Self-adjusting detachable high-locking nut assembly

A high-lock nut and self-adjusting technology, applied in the direction of nuts, threaded fasteners, locking fasteners, etc., can solve the problems of inability to achieve stable connection, unfavorable cost saving, waste of material resources, etc., to achieve enhanced self-adjustment Disassembly of the high lock nut assembly, assembly and disassembly are convenient and quick, and the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

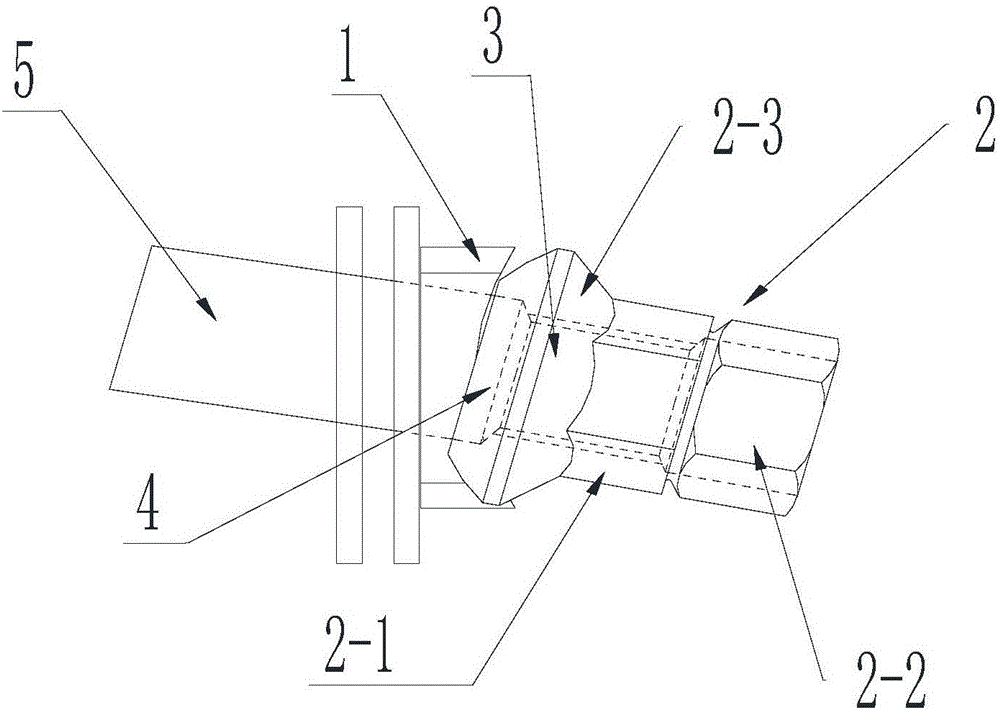

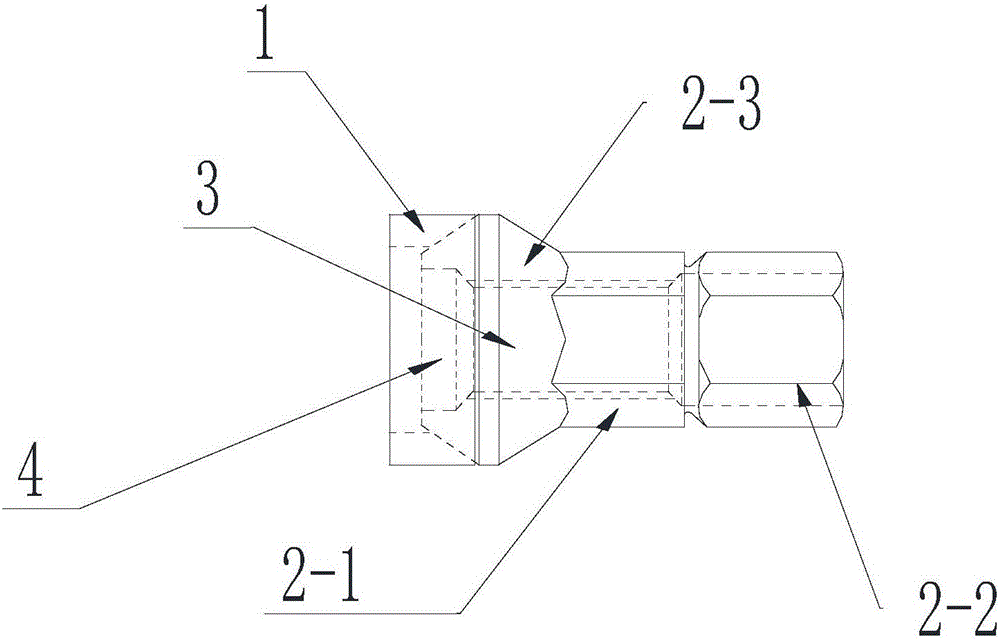

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] Such as Figure 1~4 As shown, it includes a concave spherical washer 1 and a locking piece 2, and the locking piece includes a working part 2-1 and a process part 2-2 in an integrated structure;

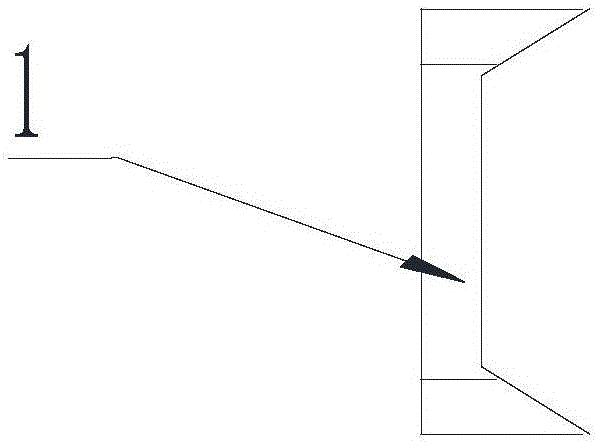

[0024] The working part 2-1 has a three-section integrated structure from front to back, the front part is a convex spherical structure, the middle part is an arc-shaped shoulder 2-3, and the rear part is an external hexagonal structure. The working part 2-1 is provided with internal threads A hole 3, the front end of the internally threaded hole 3 is provided with a flaring 4;

[0025] The front end of the concave spherical gasket 1 is a flat end surface, and the rear end is a concave spherical surface structure m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com