A Simple Method of Adding Pre-buried Pipes

A kind of pre-embedded pipe, simple technology, applied in the direction of pipeline laying and maintenance, mechanical equipment, pipe/pipe joints/pipe fittings, etc., can solve the problems of complex construction and anti-corrosion process, long construction period, complicated construction process steps, etc., to achieve the construction period Short, easy to operate, easy to construct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

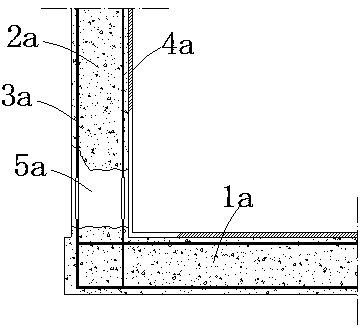

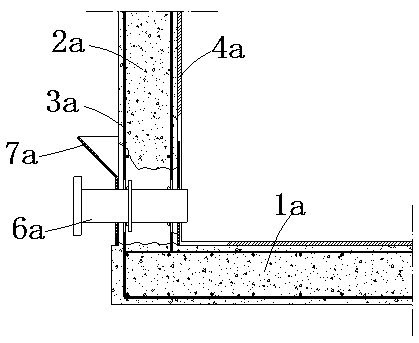

[0038] Such as Figures 1b to 6b As shown, a simple method of adding embedded pipes includes the following steps:

[0039] Step 1: Select the installation position of the embedded pipe on the bottom 1 or wall 2 of the tank and mark the positioning point;

[0040] Step 2: Drill a hole at the location of the positioning point with a water drill hole opener to form an installation hole 3 that communicates with the inner cavity of the tank. The tank wall 2 includes an outer surface 21 and an inner surface 22. 21 to the inner side 22 successively penetrate the reinforcement layer 23, the concrete layer 24 and the anti-corrosion layer 25, and the diameter of the installation hole 3 is larger than the outer diameter of the embedded pipe 4;

[0041] Step 3: coating the hole wall of the installation hole 3 with the installation hole anticorrosion layer 31 connected with the anticorrosion layer 25 on the inner surface 22 of the tank wall 2, the installation hole anticorrosion layer 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com