Two-way spiral vacuum tube structure capable of being used for air type solar heat collector

A technology of solar collectors and vacuum tubes, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of system service life decline, antifreeze leakage, paralysis, etc., to reduce the possibility of broken tubes and ensure Stability and safety, likelihood reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

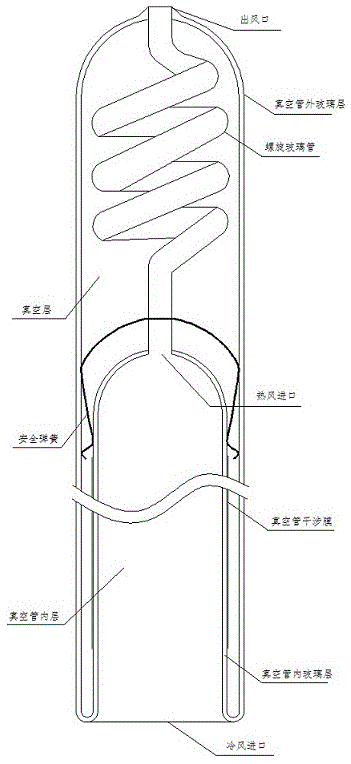

[0017] like figure 1 As shown, the present invention provides a double-pass spiral vacuum tube structure that can be used in air-type solar collectors. The double-pass spiral vacuum tube structure includes: vacuum tube outer glass layer, vacuum tube inner glass layer, spiral glass tube, vacuum tube interference film, safety Spring, vacuum layer, inner layer of vacuum tube, cold air inlet, hot air inlet and air outlet, wherein the outer glass layer of the vacuum tube is connected with the inner glass layer of the vacuum tube, the joint is the cold air inlet, one end of the spiral glass tube is connected with the inner glass layer of the vacuum tube, and the joint is It is the hot air inlet. The other end of the spiral glass tube is connected to the outer glass layer of the vacuum tube. The connection is the air outlet. The area wrapped by the inner glass layer of the vacuum tube between the cold air inlet and the hot air inlet is the inner layer of the vacuum tube. The vacuum l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com