Refrigerant piping device

A refrigerant and return pipe technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of embrittlement of the refrigerant return pipe 15, the inability of the user to continue working, and the exhaustion of the refrigerant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

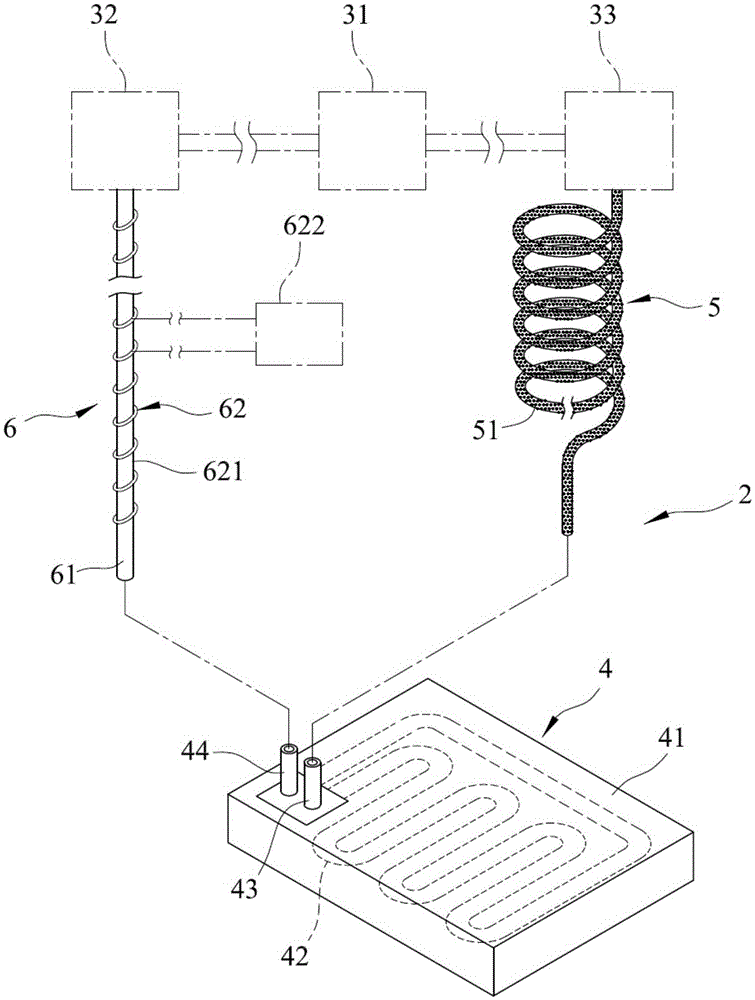

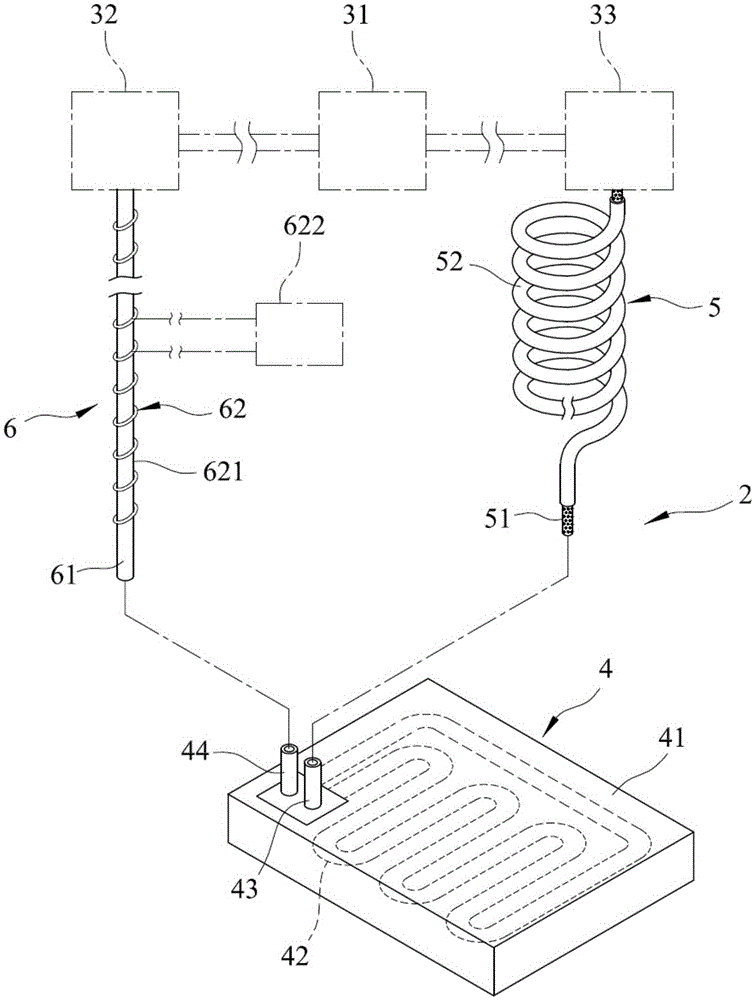

[0028] refer to figure 2 , is the first embodiment of the refrigerant piping device 2 of the present invention, the refrigerant piping device 2 is used in conjunction with a condenser 31, a compressor 32, and a refrigerant controller 33, the condenser 31, the compressor 32, and the refrigerant controller 33 is like figure 2 As shown, they communicate with each other. In the first embodiment, the refrigerant controller 33 is preferably a solenoid valve with a capillary tube. The refrigerant piping device 2 includes a refrigerant head 4 , an input unit 5 connected to the refrigerant controller 33 and the refrigerant head 4 to input refrigerant, and an output unit 6 connected to the refrigerant controller 33 and the compressor 32 to output refrigerant.

[0029] The freezing head 4 includes a main body 41, a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com