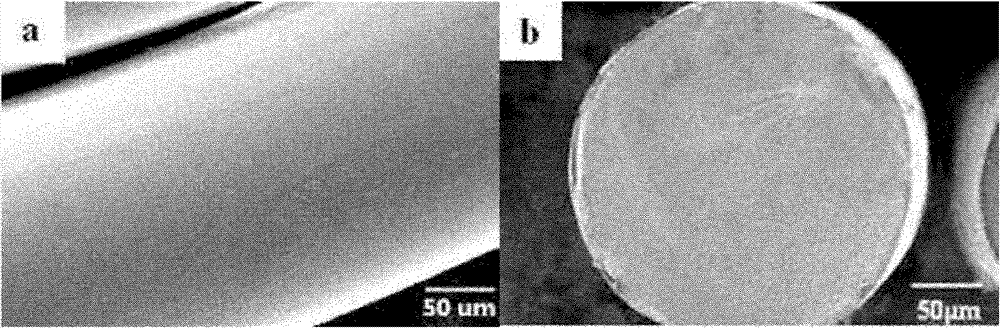

Method for preparing polyacrylonitrile-based carbon fiber precursors without skin-core structure

A technology for spinning polyacrylonitrile-based carbon fibers and polyacrylonitrile is applied in spinning solution preparation, fiber processing, drawing spinning and other directions, which can solve the problems of unfavorable comprehensive performance of precursors, increase of precursor pores, and reduction of production costs. and other problems, to achieve the effect of less defects, increased stretching ratio, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 21% (mass percentage based on the sum of the three substances) of polystyrene with a viscosity-average molecular weight of 78,000 in the dimethyl sulfoxide / water mixed solvent of 5% (based on the percentage of total mass of dimethyl sulfoxide and water) containing water. Acrylonitrile resin, stirred at a constant speed at 50°C for 3 hours to disperse and swell, stirred at 70°C for 5 hours to fully dissolve, then stood at 70°C for defoaming, and placed in a dry environment at 25°C Mature at a medium constant temperature for 3 hours, extrude through a spinneret on a twin-screw extruder, pass through a 3cm air section, and then enter a methanol extraction bath at a temperature of 25°C to solidify and form, and control the winding speed of the winding roller and the extrusion speed of the stock solution The ratio is 10. The as-spun filaments were washed and stretched 1.5 times in a water bath at 40°C, stretched 2 times and 2.5 times in hot water at 80°C and 95°C in turn...

Embodiment 2

[0035] In the dimethylacetamide / water mixed solvent of 1% (based on the percentage of total mass of dimethylacetamide and water) containing water, add 23% (based on the mass percentage of the sum of the three substances) of polystyrene with a viscosity-average molecular weight of 78000 Acrylonitrile resin, stirred at a constant speed at 50°C for 3 hours to disperse and swell, stirred at 75°C for 5 hours to fully dissolve, then stood at 75°C for defoaming, and placed in a dry environment at 25°C Mature at a medium constant temperature for 2 hours, extrude through the spinneret on the twin-screw extruder, pass through a 3cm air section, and then enter the methanol extraction bath with a temperature of 25°C to solidify and form, and control the winding speed of the winding roller and the extrusion speed of the stock solution The ratio is 10. The as-spun filaments were washed and stretched 1.5 times in a water bath at 40°C, stretched 2 times and 2.5 times in hot water at 80°C and ...

Embodiment 3

[0037]Add 23% (mass percentage based on the sum of the three substances) of polystyrene with a viscosity-average molecular weight of 78,000 in the dimethyl sulfoxide / water mixed solvent of 5% (based on the percentage of total mass of dimethyl sulfoxide and water) containing water. Acrylonitrile resin, stirred at a constant speed at 50°C for 3 hours to disperse and swell, stirred at 80°C for 5 hours to fully dissolve, then stood at 80°C for defoaming, and placed in a dry environment at 25°C Mature at a medium constant temperature for 2 hours, extrude through a spinneret on a twin-screw extruder, pass through a 3cm air section, and enter a methanol / ethanol extraction bath with a temperature of 20°C and a methanol content of 80% by mass to solidify and form. The ratio of the winding speed of the winding roll to the dope extrusion speed is 12. The as-spun filaments were washed and stretched 1.8 times in a water bath at 40°C, stretched 2 times and 2.5 times in hot water at 85°C and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com