Heat preservation type drying machine

A dryer and drying cylinder technology, which is applied to local stirring dryers, dryers, dryers for static materials, etc., can solve the problems of slow drying speed, difficult cleaning, and poor thermal insulation effect of dryers, and achieve thermal insulation effect. Good, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

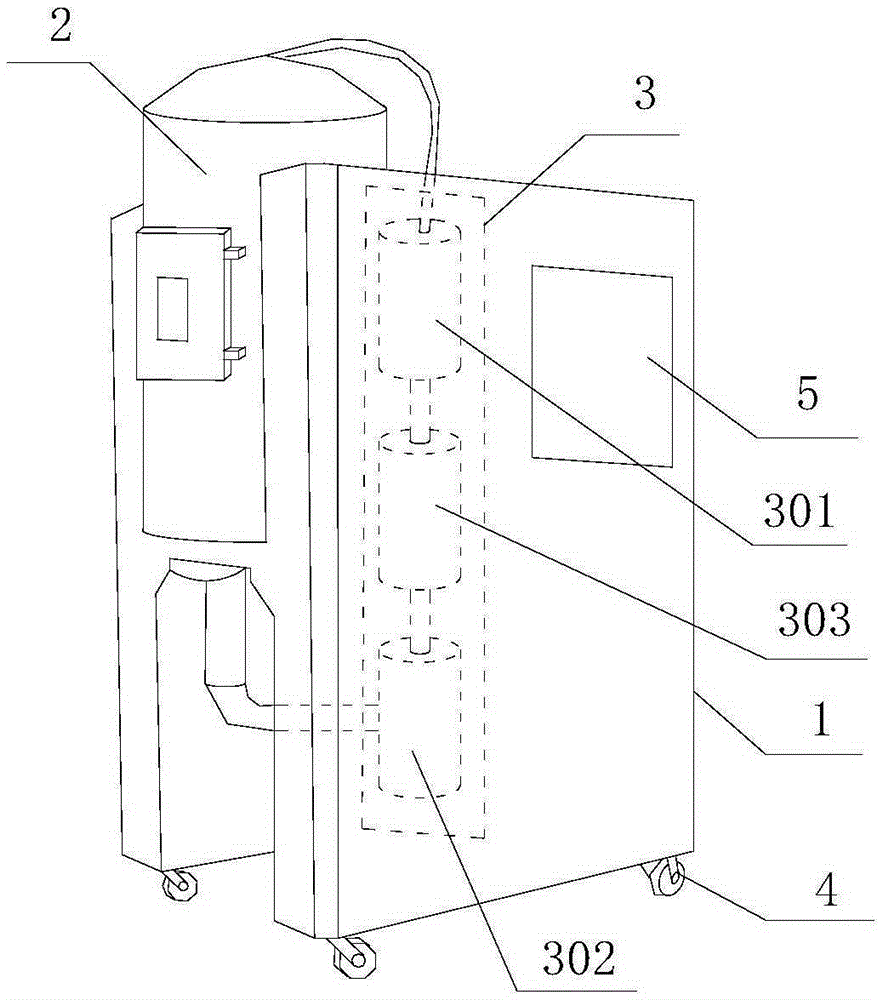

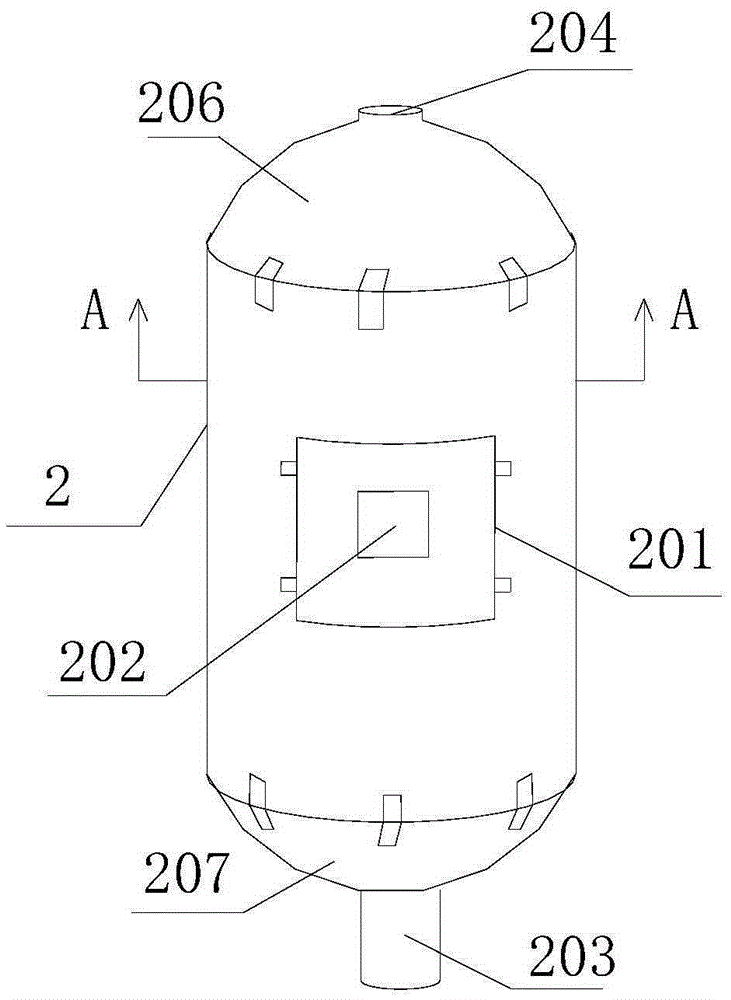

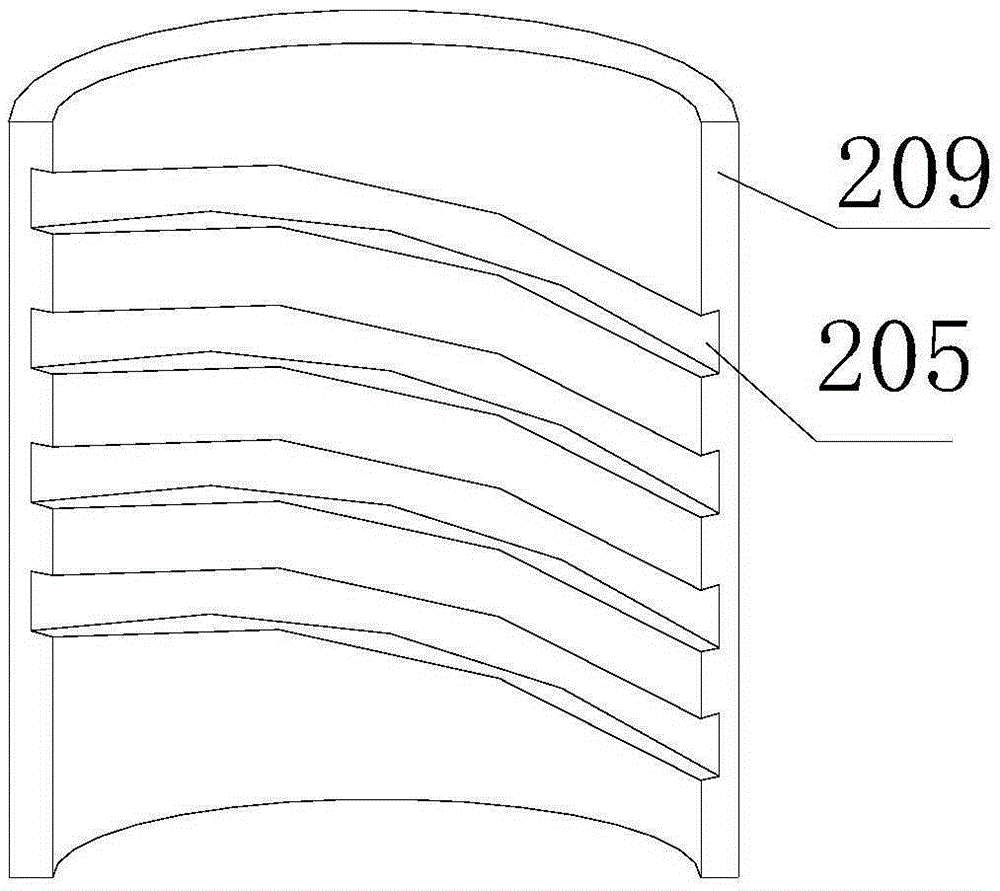

[0022] Such as Figure 1 to Figure 4 As shown, the thermal insulation dryer includes a frame 1 and a drying cylinder 2 fixed on the frame 1. The drying cylinder 2 is in the shape of a hollow cylinder, and its side is provided with a material door 201, which is matched with the inside of the material door 201. The position is provided with a material rack, the frame 1 is provided with an air inlet device 3, the air inlet device 3 includes an air pump 301, a heater 302 and a dryer 303, and the air outlet of the air pump 301 is connected to the air outlet through the dryer 303 and the heater 302 The inlet 203 at the lower end of the drying cylinder 2 and the air inlet of the air pump 301 are connected to the outlet 204 at the top of the drying cylinder 2. The top of the drying cylinder 2 is provided with an upper cover 206. The upper cover 206 is in the shape of an inverted bowl. The cylinder 2 is hinged, and the lower end of the drying cylinder 2 is provided with a lower cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com