Metal-nozzle and micro-flow water flow sensor

The technology of a water flow sensor and elastic metal sheet is applied in the field of metal nozzle micro-flow water flow sensor, and can solve the problems of no application value, measurement error, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

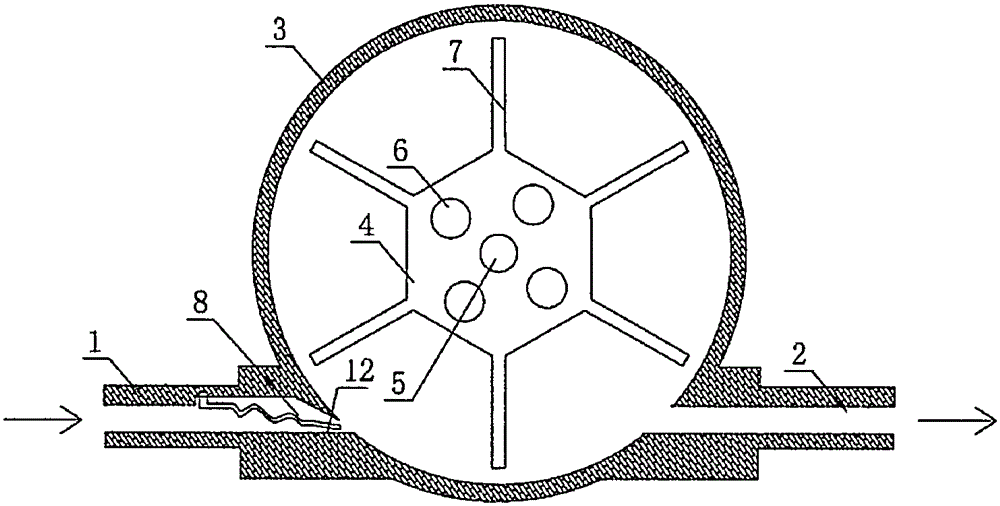

[0012] figure 1 Among them, the water flow sensor includes a main component housing (3), the front and rear ends of the housing (3) respectively have a water inlet (1) and a water outlet (2), the housing (3) is equipped with an impeller (4), and the impeller ( 4) There are impeller shafts (5), magnets (6), and impeller blades (7).

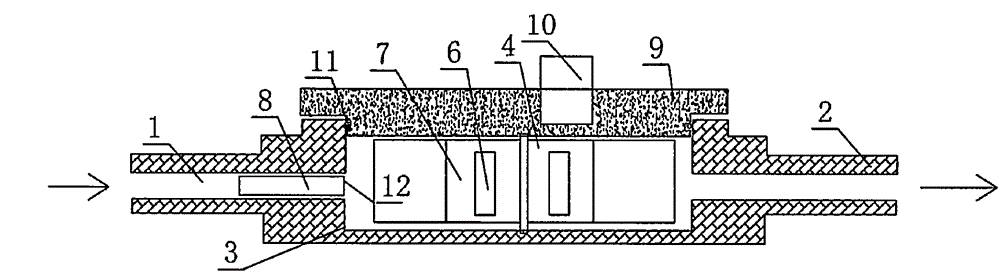

[0013] figure 2 Among them, an upper cover (9) is arranged on the opening of the housing (3), and a sealing ring (11) is arranged between the housing (3) and the upper cover (9). The upper cover (9) is equipped with an induction head (10) near the magnet (6). The magnet (6) rotates with the impeller (4). The induction head (10) senses the switching of the magnetic field of the magnet (6) and converts it into a pulse signal. The head (10) transmits the pulse signal to the metering circuit unit.

[0014] The water inlet (1) is provided with an elastic metal sheet (8), and one end of the elastic metal sheet (8) narrows an angle with the water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com