Layer structure of the ballistic armor module

A layer structure and armor technology, which is applied in the structure of armor plates, armored vehicles, transportation and packaging, etc., can solve the problems of poor damping performance, difficult disassembly of armor, and low strength of layered composite structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

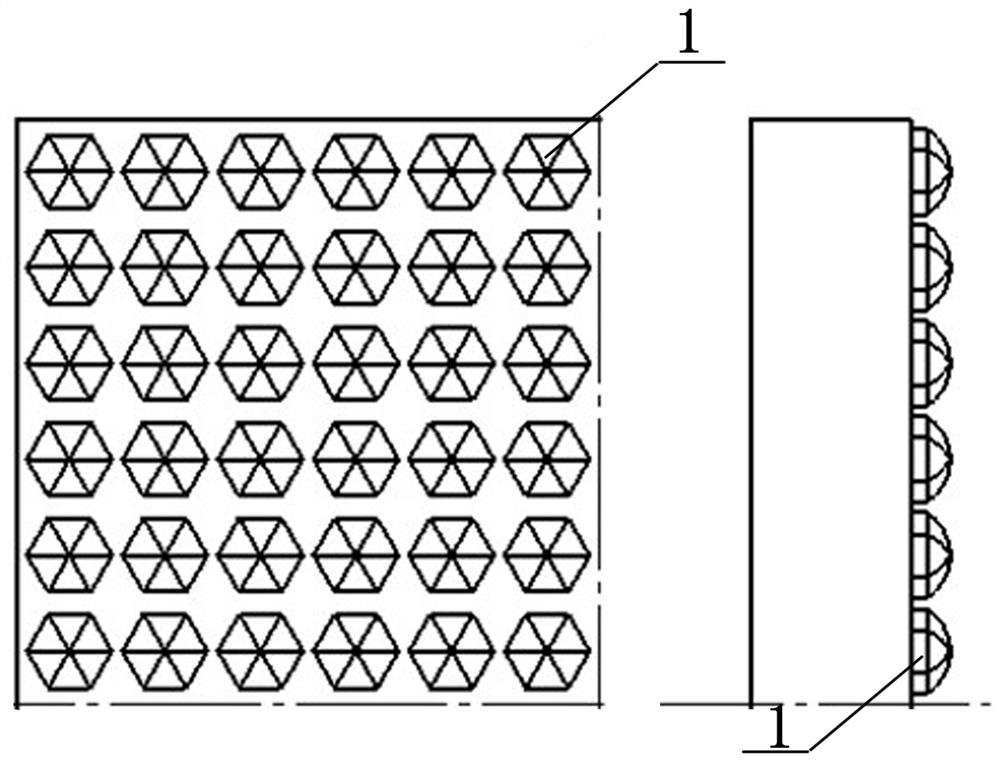

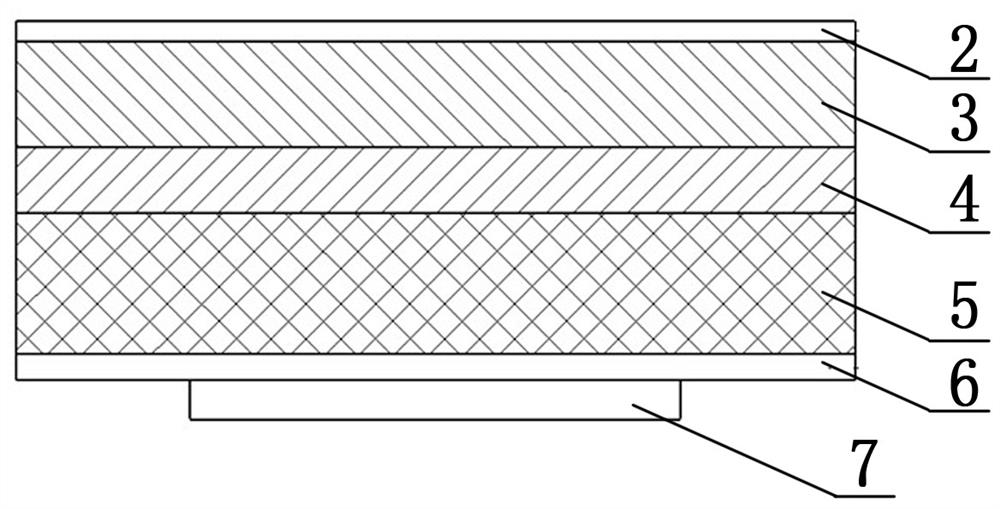

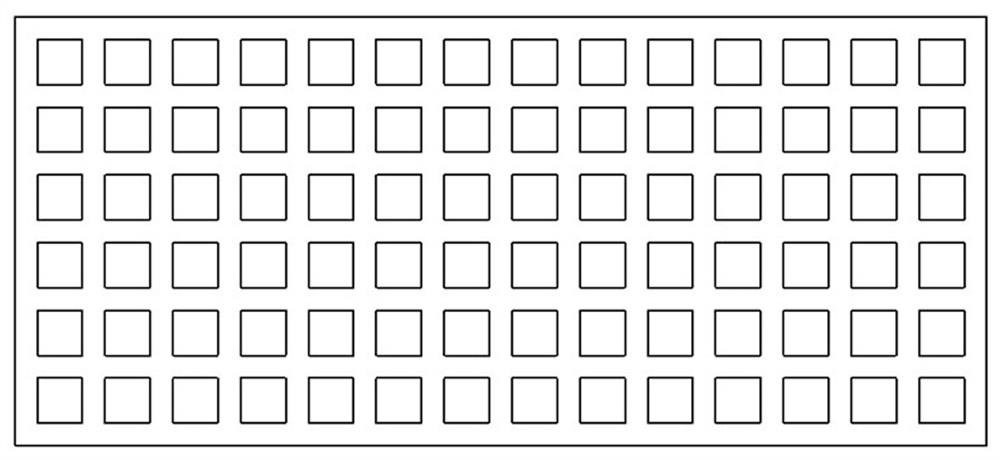

[0021] according to Figure 1~3 The specific structure of the present invention will be described in detail. The layer structure of the bulletproof armor module includes a skin, a neoprene layer, a ceramic layer, a foamed aluminum layer, and a titanium alloy layer arranged sequentially in the restraint box from outside to inside. The bottom of the constraint box is provided with a flange, and the outside of the ceramic layer is a crown structure. The restraint box is formed by punching and stretching titanium or aluminum metal plates. The structure of each layer is sealed and welded in the box by pressure assembly method, and is bound in the box by the elastic force of the rubber plate. The above-mentioned structure is made into a modular bulletproof armor, which then includes a grid plate, a modular armor with the bottom flanges of some restraint boxes fixed on the grid plate.

[0022] The skin has a density of 4.49~5.53g / cm 3 Made of titanium alloy, thickness 0.5mm, densi...

Embodiment 2

[0030] The thickness of the skin is 0.6mm, the thickness of the ceramic layer is 16.0mm, the thickness of the neoprene layer is 8.0mm, the thickness of the aluminum foam layer is 20.0mm, and the thickness of the titanium alloy layer is 8.0mm. The titanium alloy is composed of the following components, aluminum 7.9wt%, molybdenum 0.9wt%, vanadium 0.9wt%, titanium 90.3wt%.

Embodiment 3

[0032] The thickness of the skin is 0.8mm, the thickness of the ceramic layer is 14.0mm, the thickness of the neoprene layer is 10.0mm, the thickness of the aluminum foam layer is 18.0mm, and the thickness of the titanium alloy layer is 6.0mm. The titanium alloy is composed of the following components, aluminum 8.0wt%, molybdenum 0.9wt%, vanadium 1.1wt%, titanium 90.0wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com