Instrument valve control method and instrument valve control device

A valve control and valve technology, which is applied in the field of automatic control, can solve the problems of inability to complete the normal opening and closing of valves, and inability to detect valve status in real time, and achieve the effect of avoiding communication signal interference, precise valve control function, and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

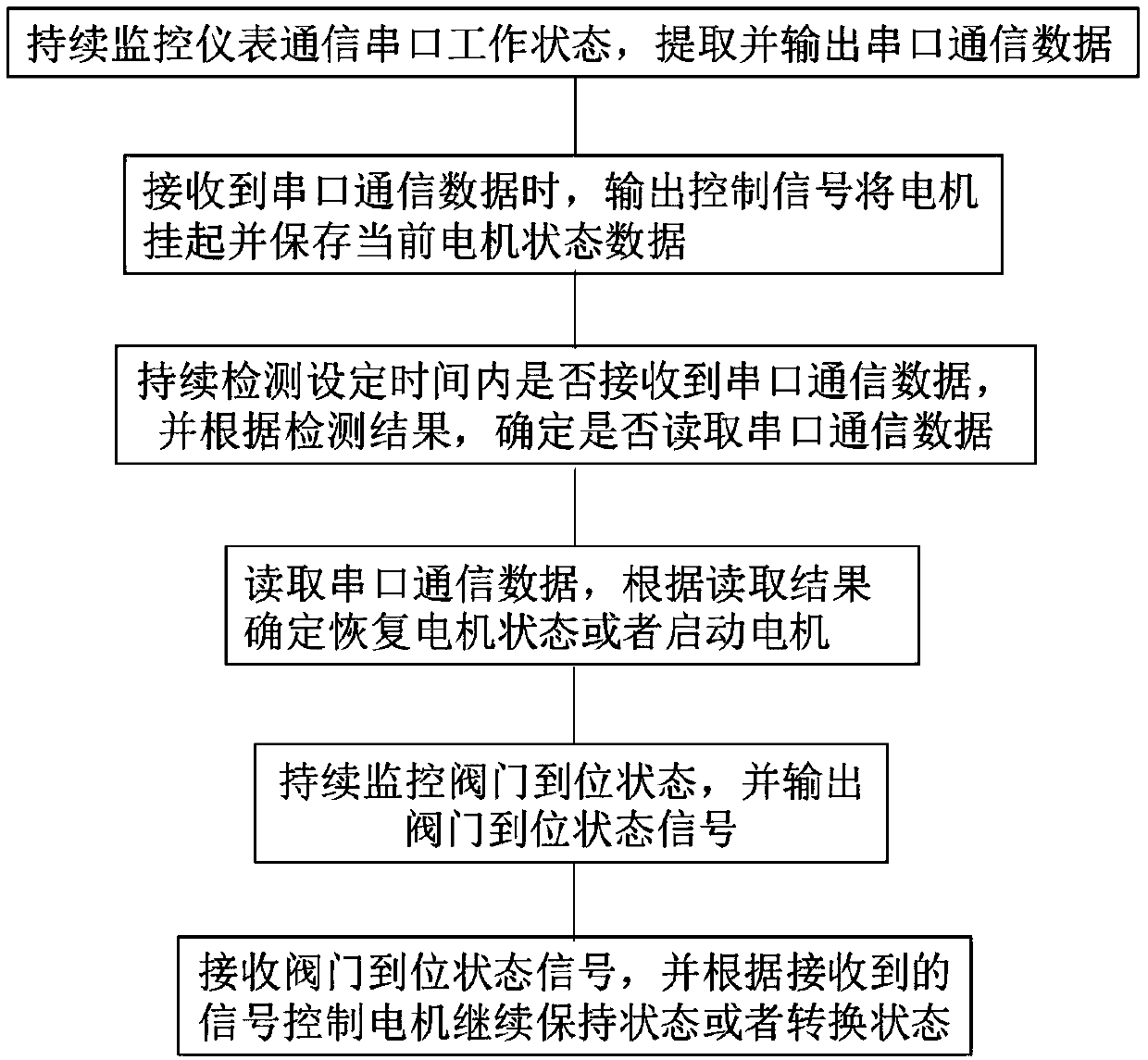

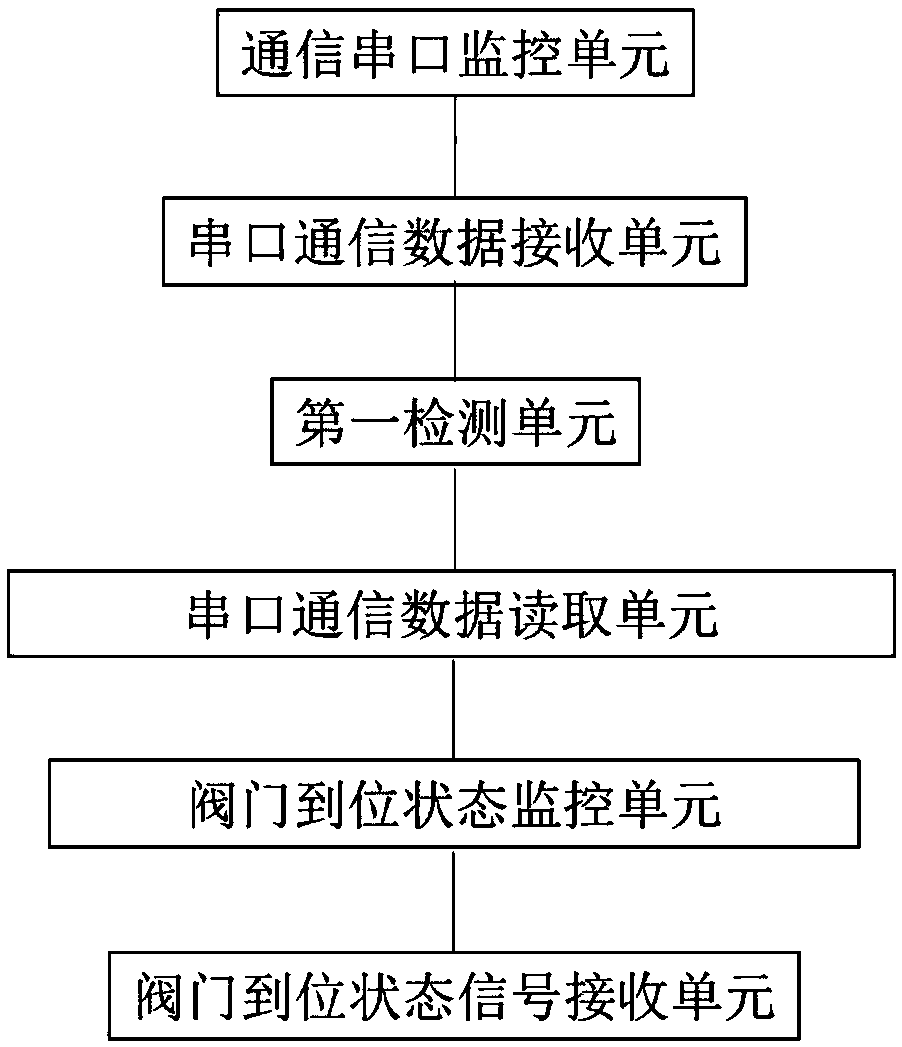

[0064] Such as figure 1 As shown, the present invention provides an instrument valve control method, comprising the following steps:

[0065] Continuously monitor the working status of the instrument communication serial port, extract and output serial communication data;

[0066] When the serial communication data is received, the output control signal will suspend the motor and save the current motor state data;

[0067] Continuously detect whether the serial communication data is received within the set time, and determine whether to read the serial communication data according to the detection result;

[0068] Read the serial communication data, and determine to restore the motor state or start the motor according to the read result;

[0069] Continuously monitor the valve in-position status, and output the valve in-position status signal;

[0070] Receive the valve in-position status signal, and control the motor to continue to maintain the status or switch the status ...

Embodiment 2

[0072] The invention provides a method for controlling an instrument valve, comprising the following steps:

[0073] Continuously monitor the working status of the instrument communication serial port, extract and output the serial port communication data, the serial port communication data can be commands related to valve action, or other communication content;

[0074] When the serial port communication data is received, the output control signal will suspend the motor and save the current motor state data. In this step, receiving the serial port communication data means that the serial port starts to communicate. Motor state data, that is, if the current motor is in the "action" or "end" state, the control will convert the motor to the "standby" state and save the current motor "action" or "end" state, if the current motor is in the "standby" state " or "idle" status, the motor status will not change, only the current motor status will be saved;

[0075] Continuously detec...

Embodiment 3

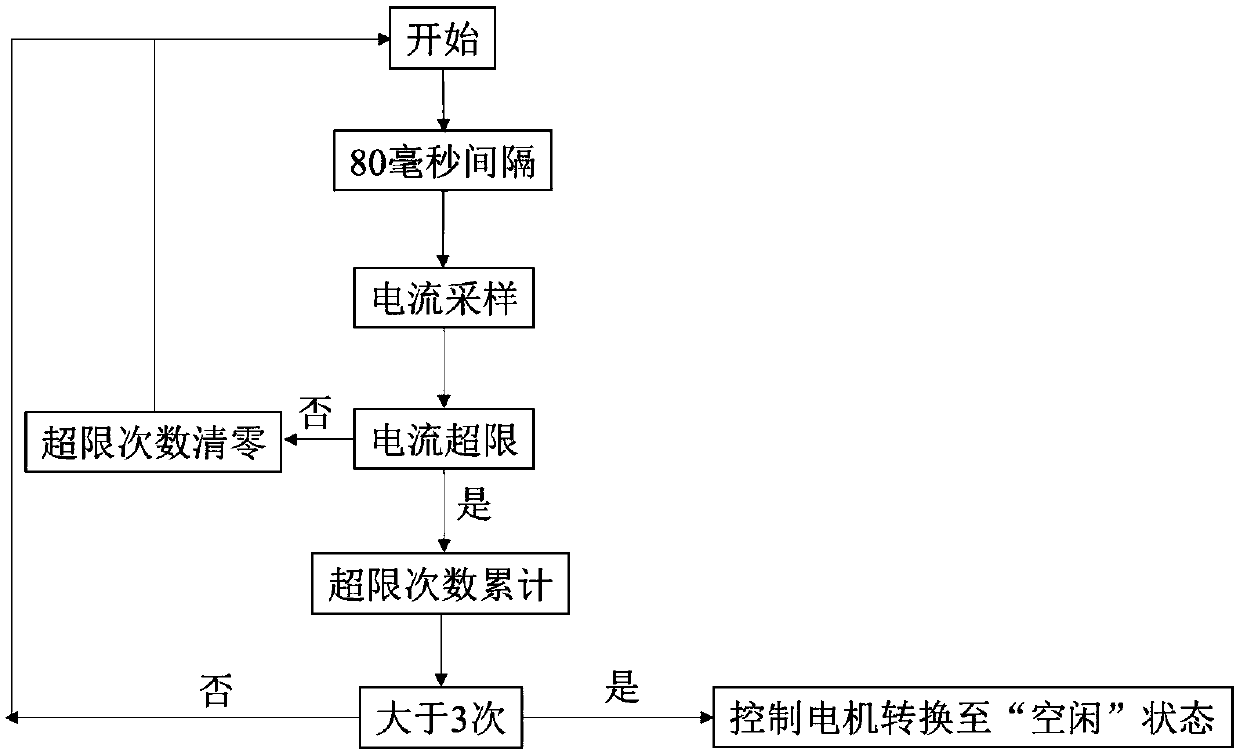

[0080] On the basis of embodiment 2, in further embodiment 3, the instrument valve control method of the present invention also includes, while continuously monitoring the valve in-position state and outputting the valve in-position state signal, continuously monitoring the valve action time signal, and according to the valve The action time signal controls the maintenance or conversion of the motor state; and continuously monitors the motor current signal, and controls the maintenance or conversion of the motor state according to the motor current signal.

[0081] Specifically, if the valve action time does not exceed the predetermined time, the control motor remains in the "acting" or "end" state, or if the valve action time exceeds the predetermined time, the control motor turns into an "idle" state. Here, according to the actual situation, set the predetermined time of the valve action time.

[0082] At the same time, if the motor current signal does not exceed the limit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com