Commutation torque ripple suppression device and suppression method for brushless DC motor

A technology for brush DC motor and pulsation suppression, which is applied in the field of device for suppressing brushless DC motor commutation torque pulsation and brushless DC motor control device, can solve the problems of errors in the manufacturing process, influence of DC brushless motor, non-commutation Phase current fluctuations and other issues, to achieve the effect of low cost, easy transformation and upgrading, and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

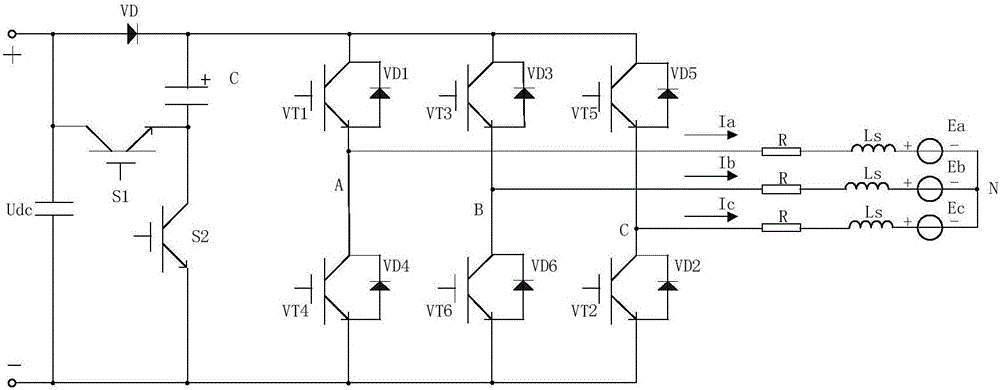

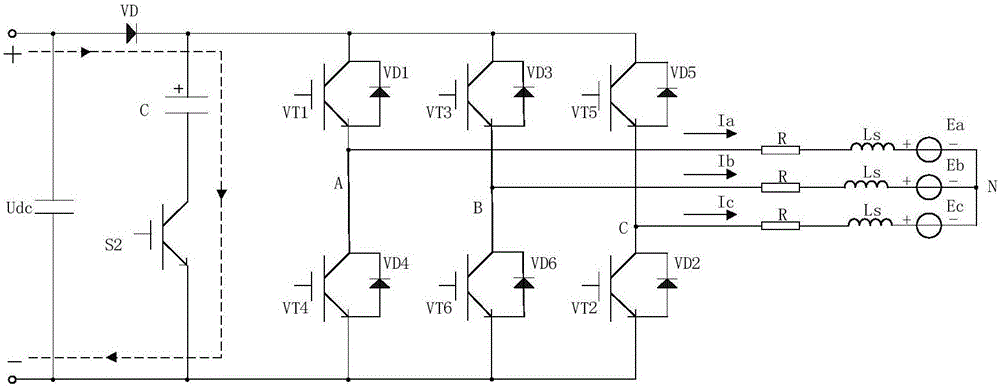

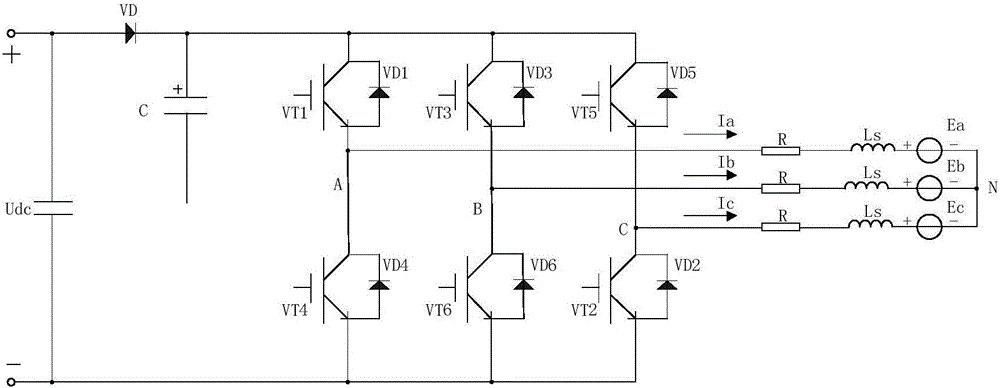

[0032] The parameters of the brushless DC motor used in the present invention are: rated power 3.7kW, rated voltage 300V, rated speed 1500rmp, inductance 0.188mH, back electromotive force coefficient 0.592. In this example, the voltage across the capacitor is charged to 90V.

[0033] image 3 In (a), the DC bus voltage during the non-commutation period is the power supply voltage 300V, and the DC bus voltage during the commutation period is the sum of the power supply voltage and the capacitor voltage 390V. Figure 4 It is the three-phase current waveform diagram and the torque waveform diagram of the embodiment without using the method of the present invention. From Figure 4 It can be seen from the figure that during commutation, the rate of commutation current decrease and rate of increase are not equal, and the commutation torque ripple is relatively large. At this time, the torque is 22N*m, the minimum torque value is 17N*m during commutation, and the torque change rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com