Liquid-cooled board card module for multipoint temperature monitoring

A multi-point temperature and board technology, applied in the computer field, can solve the problems of complexity, different heating power, different sizes, etc., and achieve the effects of high structural integration, good heat dissipation effect and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

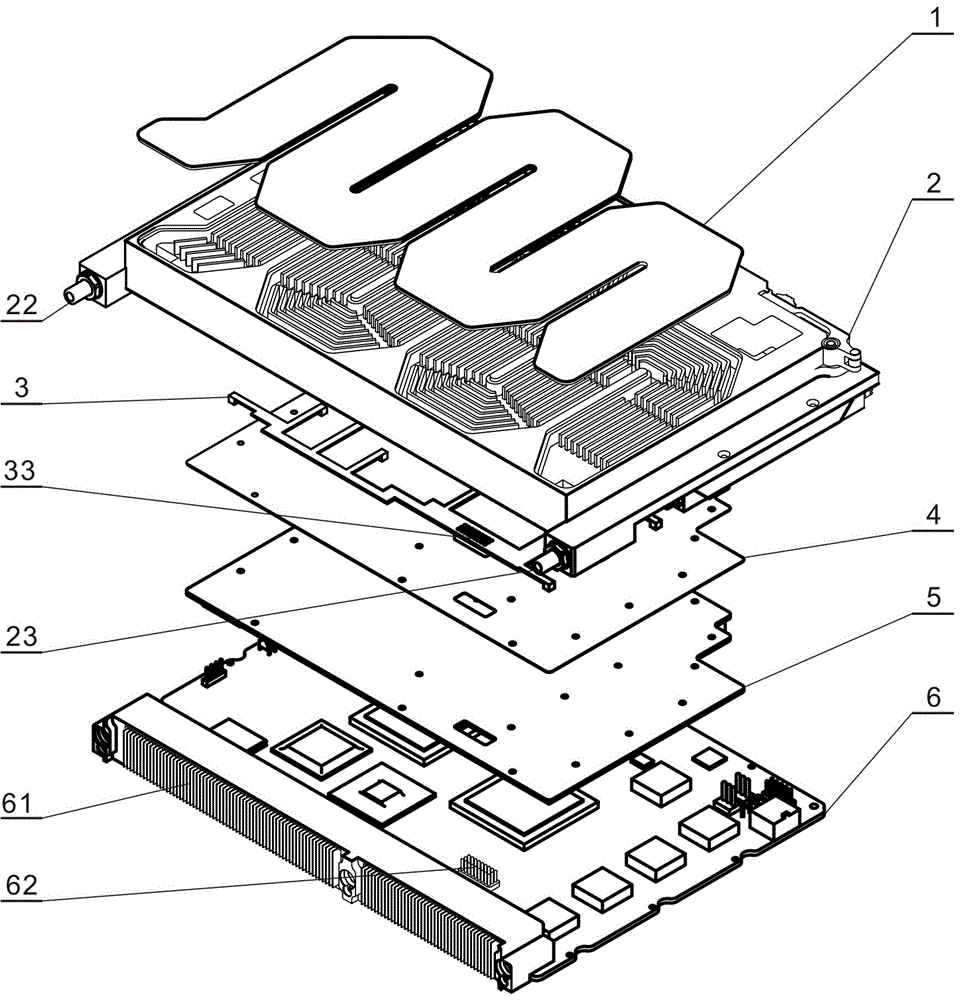

[0019] refer to figure 1 , the present invention includes a flow channel cover plate 1, a cold plate module 2, a sensor flexible component 3, a heat-conducting colloid 4, a heat-conducting copper plate 5, and a circuit board 6;

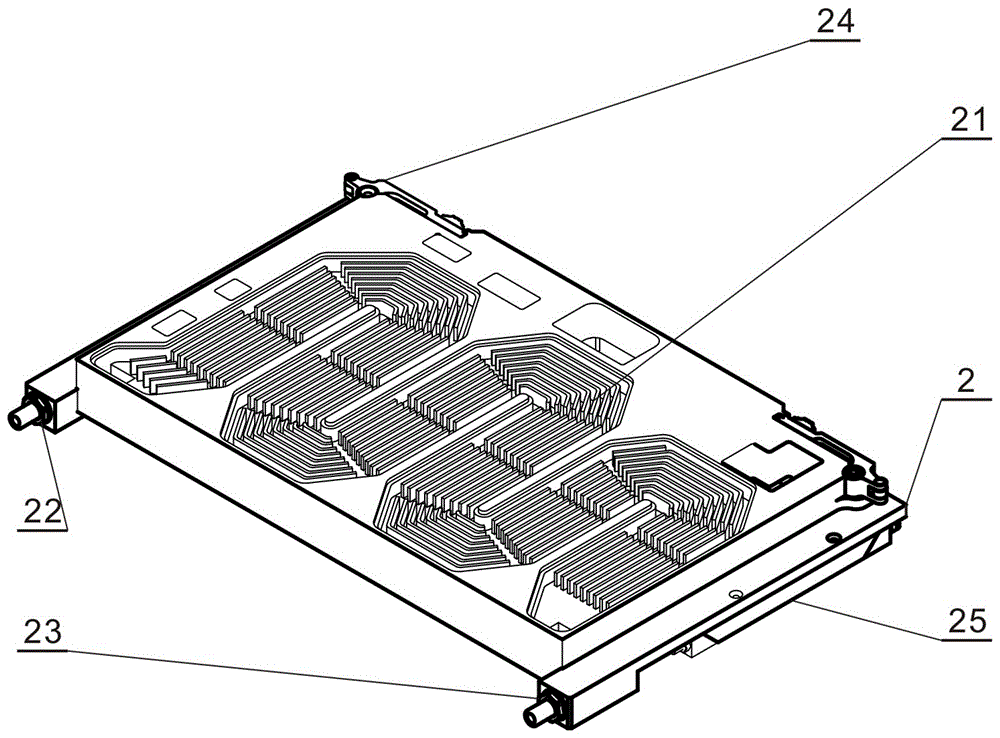

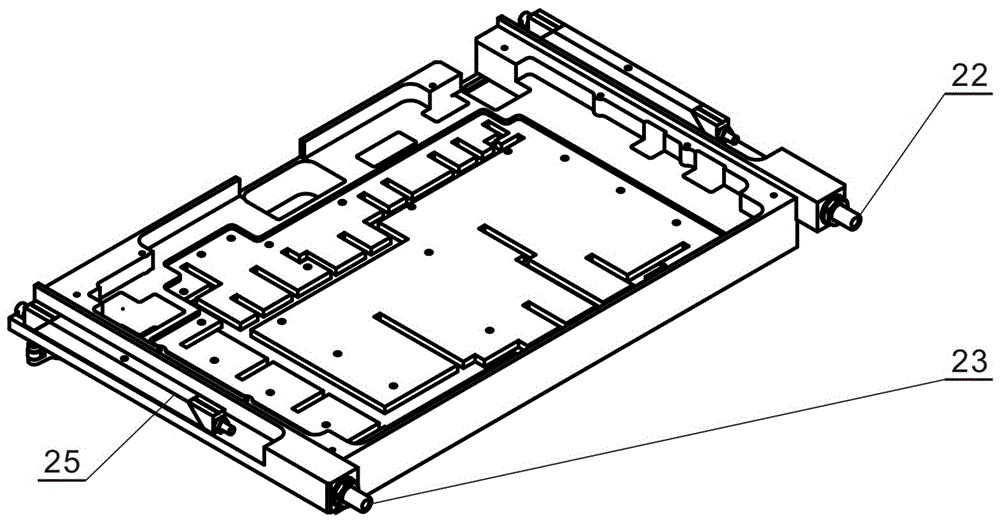

[0020] refer to figure 1 , figure 2 , image 3 , the cold plate module 2 is a module part provided with a flow channel 21, a liquid inlet 22, and a liquid outlet 23, and the outer side of the module is provided with a puller 24 and a wedge-shaped strip 25;

[0021] refer to figure 1 , Figure 4 , the sensor flexible assembly 3 is a flexible printed board 31 provided with a sensor signal socket 33, the flexible printed board 31 is provided with a plurality of heat conduction nodes, and each heat conduction node is provided with a temperature sensor 32;

[0022] refer to figure 1 , Figure 6 , the heat-conducting copper plate 5 is provided with several protrusions 51;

[0023] refer to figure 1 , Figure 7 , the circuit board 6 is a printed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com