Frog farming method and frog cage

A technology for frogs and frog cages, which is applied in animal houses, applications, animal husbandry, etc., can solve the problems of low efficiency, and achieve the effects of low cost of cage breeding, high reproduction rate, and high transformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

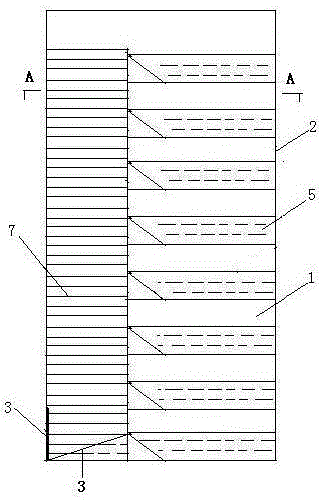

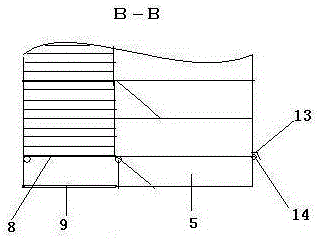

[0030] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0031] The frog cages for this kind of frog breeding are divided into fixed-point frog cages and vehicle-mounted frog cages. The outside is surrounded by a cover net 2.

[0032] The structure of the fixed-point frog cage is as follows. The frog cage is a cube, including four-cornered vertical bars 4 and 5 layered horizontal bars 14 of the Japanese font, and each layer is 10-15 cm high, depending on the size of the frogs cultivated in various places. It is determined that the 6 faces of the overall frog cage are surrounded by the cover net 2. The mesh is the lower limit that small frogs cannot escape, and the aperture is 10-20mm. The upper limit is that natural enemies cannot enter, and the aperture is 20-30mm, but insects can easily enter. Cover net 2 surface will be smooth as far as possible, in order to prevent the skin of bruising frog, there is a dodge door 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com