Method for processing Maoshan Cuimei tea

A processing method, the technology of Cuimei tea, is applied in the processing field of Maoshan Cuimei tea, which can solve the problems of high water content in green leaves, long drying time of tea leaves, and dark tea color, so as to achieve easy management, reduce drying time, increase The effect of moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A processing method of Maoshan Cuimei tea, comprising the following steps:

[0020] 1) Raw material preparation: use one bud and one leaf, one bud and two leaves as raw materials, spray Maoshan Cuimei tea leaves and turn them over at the same time to ensure uniform spraying (the amount of spraying only needs to meet the water droplets on the leaves of the tea leaves) ), then put it into the cold storage for 0.5h, and the temperature of the cold storage is -5°C, and then quickly transfer to a constant temperature dark room with a temperature of 100°C for processing, and simultaneously vacuumize it to 0.2MPa, and the processing time is 0.5h, and then take out the Maoshan Cuimei tea leaves;

[0021] 2) Spreading: Spread the Maoshan Cuimei tea leaves taken out in step 1) naturally for 10 hours, and the spreading thickness is 2.5cm;

[0022] 3) Finishing: Use a drum fixing machine, start feeding when the temperature in the cylinder is 260°C, feed the leaves at a rate of 40kg...

Embodiment 2

[0028] A processing method of Maoshan Cuimei tea, comprising the following steps:

[0029] 1) Raw material preparation: use one bud and one leaf, one bud and two leaves as raw materials, spray Maoshan Cuimei tea leaves and turn them over at the same time to ensure uniform spraying (the amount of spraying only needs to meet the water droplets on the leaves of the tea leaves) ), then put it into the cold storage for 0.2h, and the temperature of the cold storage is -10°C, and then quickly transfer to a constant temperature dark room with a temperature of 90°C for processing, and at the same time, vacuumize it to -0.1MPa, and the processing time is 1h, and then take out the Maoshan Cuimei tea leaves ;

[0030] 2) Spreading: Spread the Maoshan Cuimei tea leaves taken out in step 1) naturally for 8 hours, and the spreading thickness is 2cm;

[0031] 3) Finishing: Use a drum fixing machine, start feeding when the temperature in the cylinder is 260°C, feed the leaves at a rate of 45k...

Embodiment 3

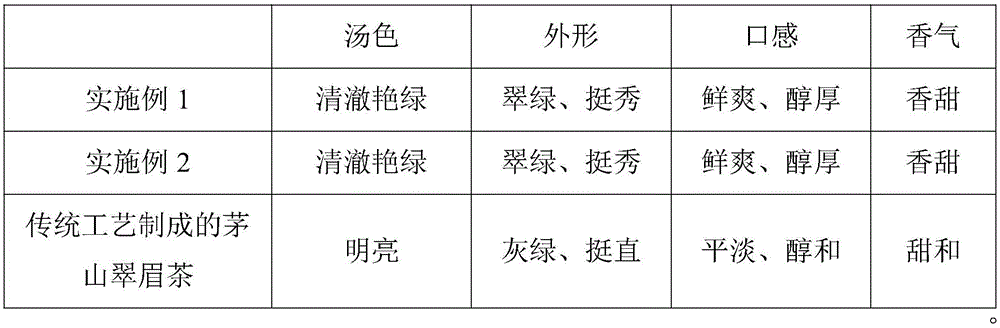

[0037] The Maoshan Cuimei tea obtained in Example 1-2 was subjected to sensory evaluation, and the results are shown in Table 1:

[0038] Table 1 Sensory evaluation results

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com