Tea base steaming device and in-mold steaming molding process

A technology of steaming and tea base, applied in the direction of tea processing before extraction, can solve the problems of unfriendly working environment, large labor and material resources, etc., and achieve the effect of reducing secondary pollution opportunities, saving labor, and uniform steaming degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments.

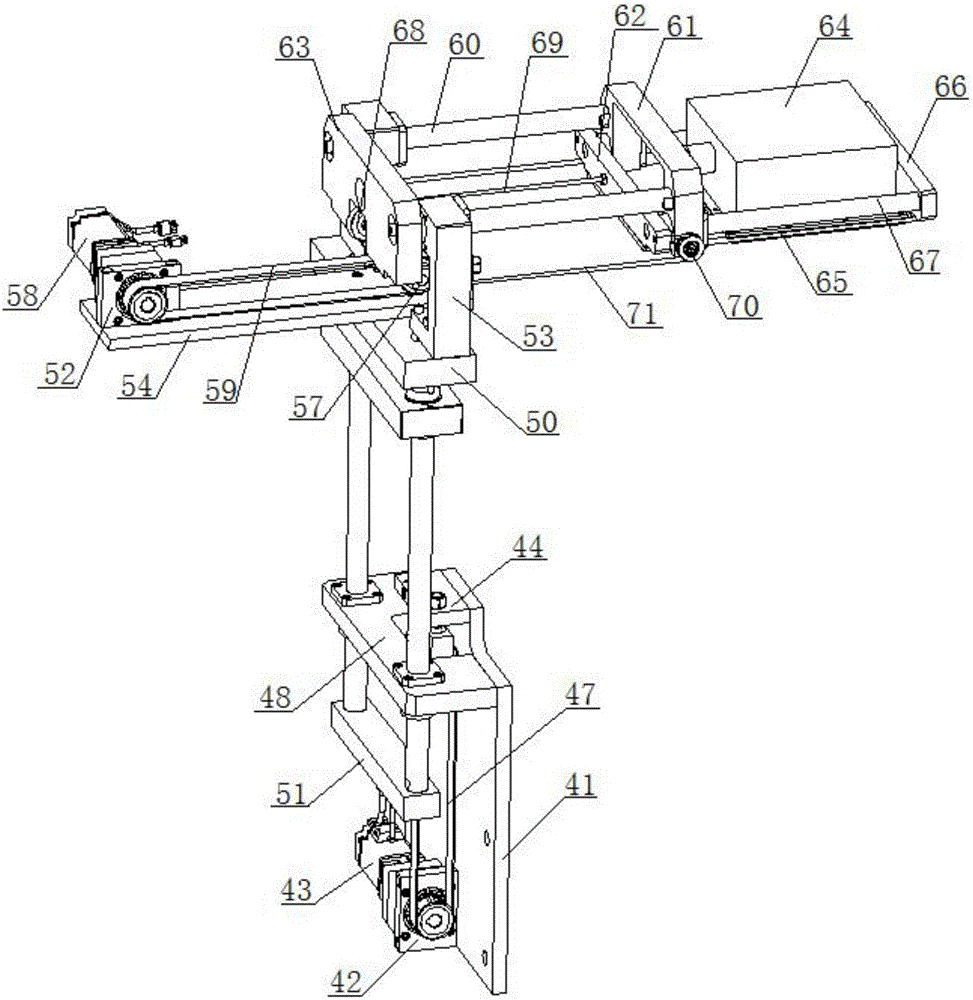

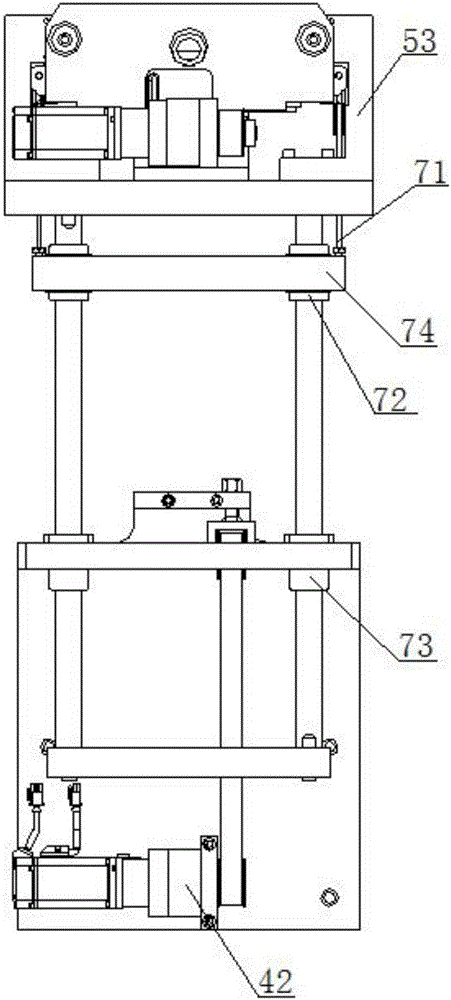

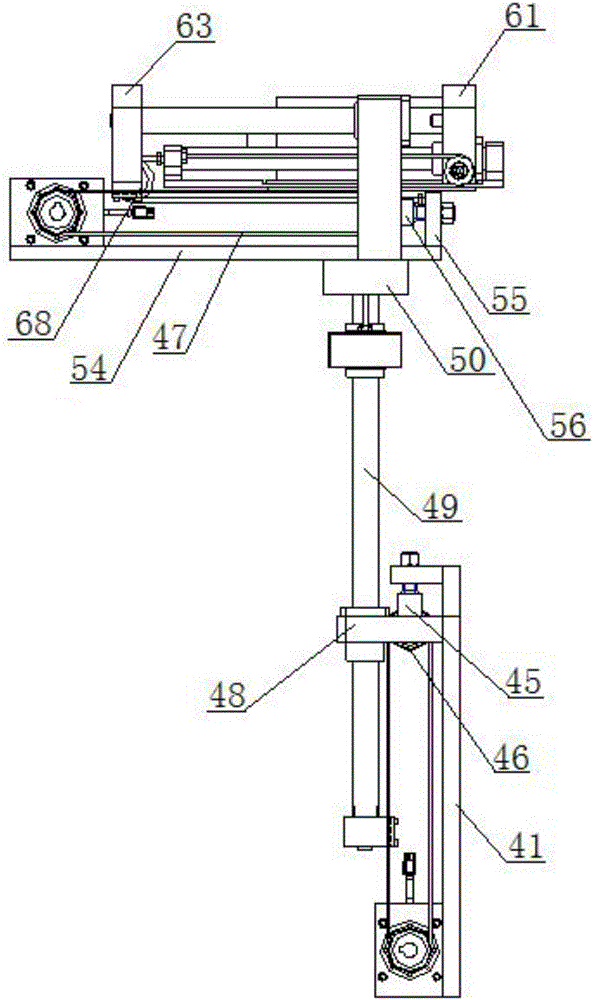

[0036] see Figure 1 to Figure 12 , a steaming device used in conjunction with an oil press, including a pressing mold and a steaming assembly.

[0037] see Figure 1 to Figure 5 , the steaming assembly includes a vertical plate 41 , a connecting plate 1 50 and a connecting plate 2 51 . The lower part of the vertical plate 41 is provided with a lifting motor 43 through the motor support I42, and the top of the vertical plate 41 is provided with a pull plate I44; the pull plate I44 is provided with a pulley I46 through a pulley seat I45, so The lifting motor 43 and the pulley 146 are connected through the synchronous belt 147, and the connecting plate 2 51 is connected with the synchronous belt 147.

[0038] see Figure 1 to Figure 5 , the upper end of the vertical plate 41 is provided with a side vertical plate 48, and the lower part of the connecting plate 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com