Food cleaning treatment apparatus

A cleaning and food technology, applied in food preservation, food processing, food science, etc., can solve the problem of low utilization rate of heat energy, achieve the effect of improving utilization rate and preventing leakage of high-temperature steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

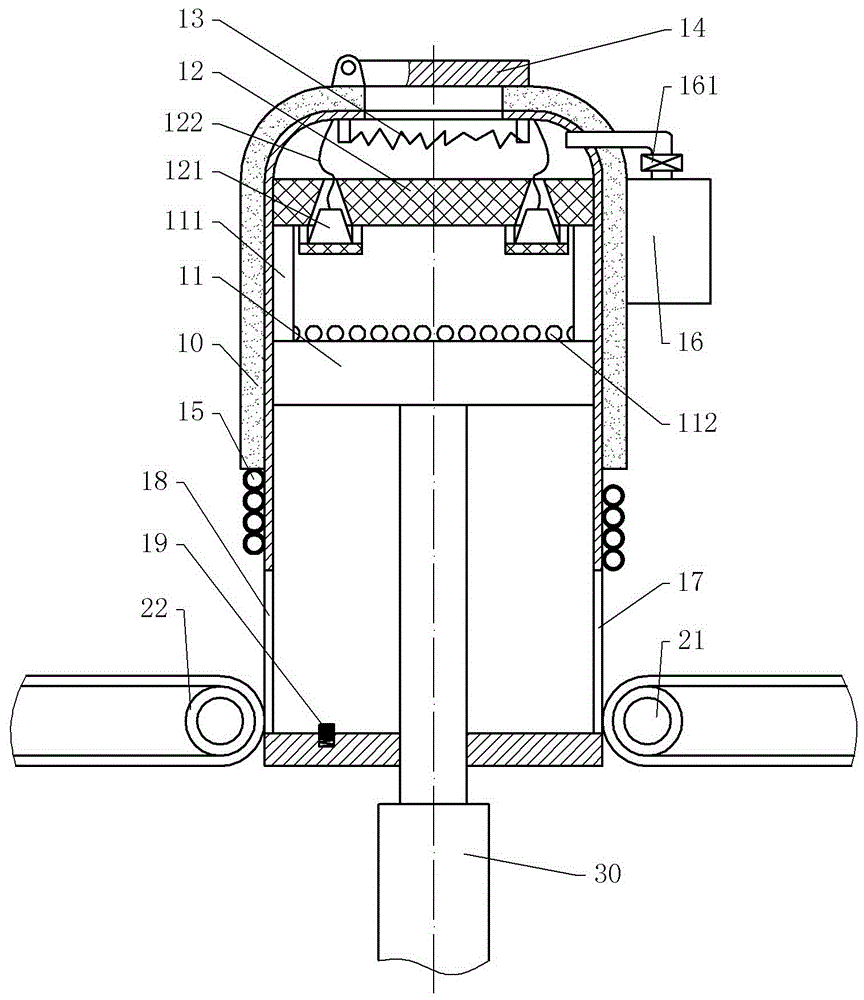

[0021] The reference signs in the drawings of the description include: sterilization cylinder 10, load bearing plate 11, support 111, roller shaft 112, sealing plate 12, cone truncated 121, pull rope 122, heating wire 13, sealing cover 14, cooling water circulation pipe 15. Steam chamber 16, air control valve 161, material inlet 17, material outlet 18, linkage switch 19, material inlet 21, material outlet 22, hydraulic cylinder 30.

[0022] The embodiment is basically as figure 1 Shown:

[0023] The food cleaning treatment device of the present embodiment comprises a sterilizing cylinder 10, a steam chamber 16, a conveying part and a lifting mechanism, the sterilizing cylinder 10 is vertically arranged, and the top of the sterilizing cylinder 10 is provided with a heating device and a temperature sensor. The device includes a heating wire 13 and a controller, the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com