A kind of preparation method of meat floss

A production method and the technology of meat floss, which are applied in the direction of food science, etc., can solve the hidden dangers of manual contact with high-temperature hot oil, the difficulty of ensuring the amount and uniformity of oiling, and uneven oiling, etc., to achieve convenient spraying of mist edible oil, Accelerates the evaporation of water and increases the effect of fresh and fragrant taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

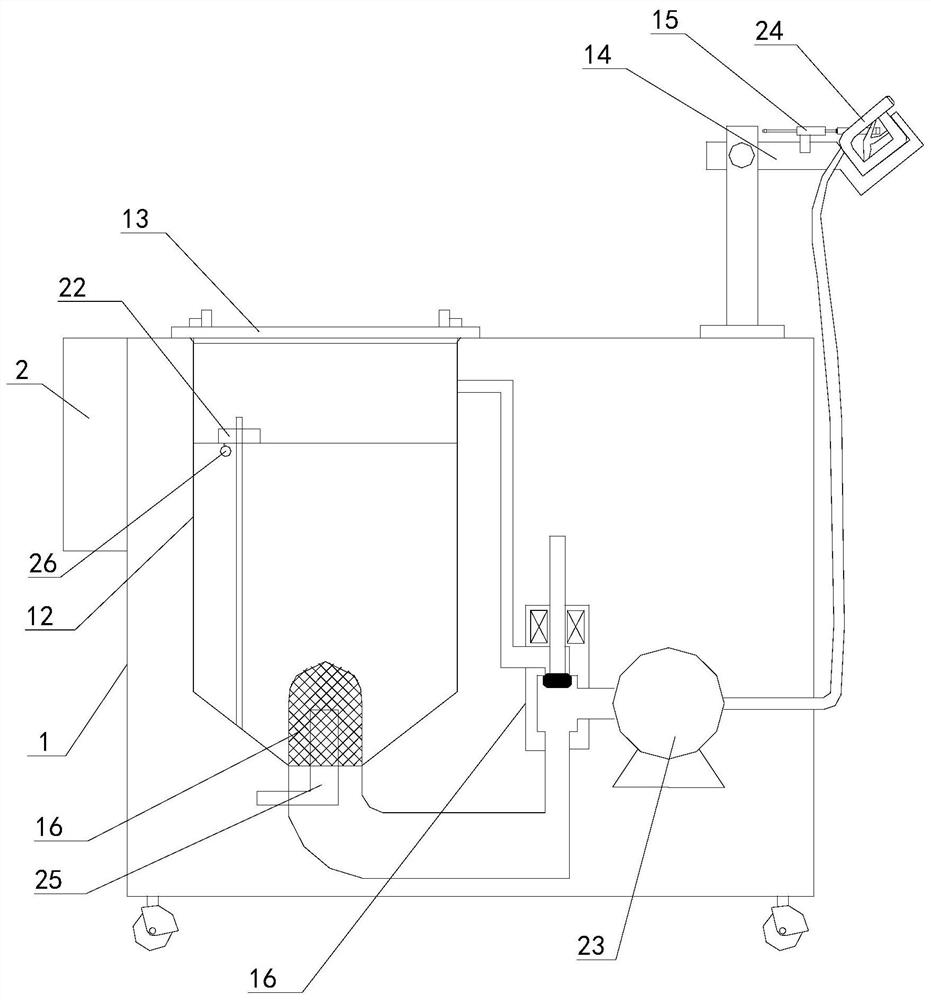

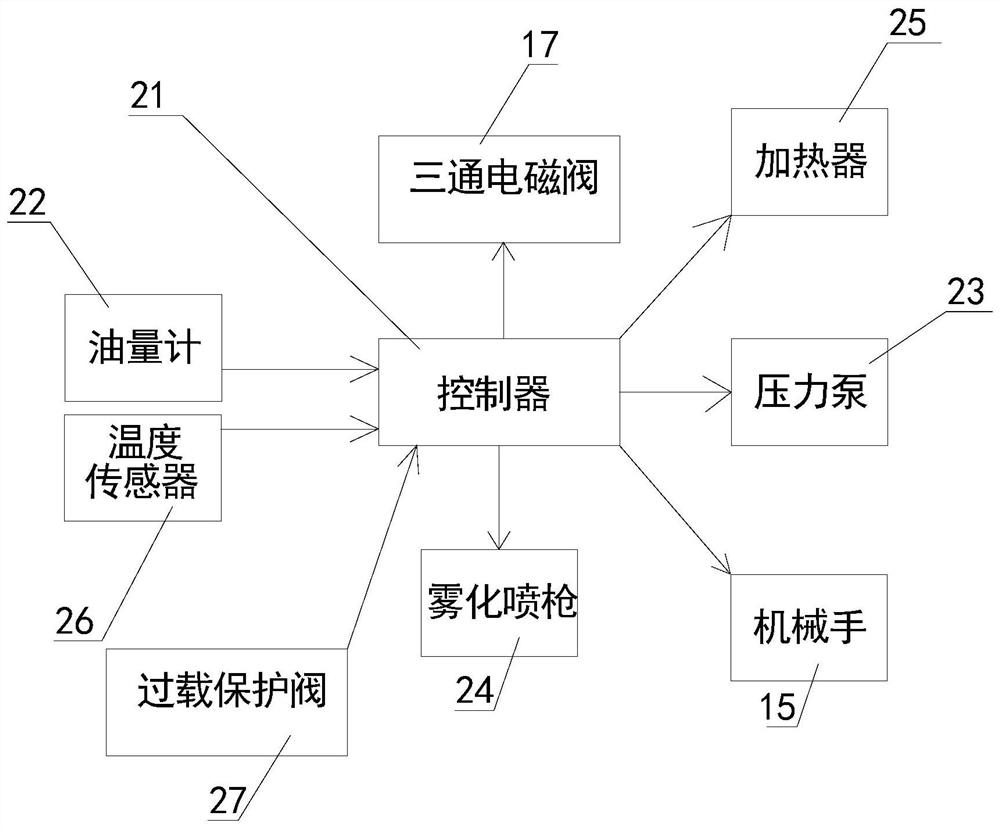

[0031] A method for making meat floss, which comprises the following steps: fresh pork is sorted and cut into pieces, steamed for 180 minutes at a temperature of 95° C., crushed, and wire-drawn; fried once after being mixed with seasoning; fried for the second time after cooling, and fried twice. Add edible oil during frying; cool and pack after taking out of the pan to obtain the finished product; it is characterized in that, adding edible oil in the second frying is to use edible oil mist spraying equipment to add 120°C and a particle size of 500μm. cooking oil.

[0032] The one-time frying includes the following steps: initial frying at 100° C. for 80 minutes; flossing and then frying at 150-180° C. for 40 minutes, the moisture content of the dried meat floss is 20%, and the meat floss is taken out of the pan to cool.

[0033] The secondary frying is frying at a temperature of 200°C for 40 minutes, spraying mist edible oil when the moisture content of the meat floss is 6%, ...

Embodiment 2

[0040] A method for making meat floss, which comprises the following steps: fresh mutton or beef is arranged and cut into pieces, steamed at a temperature of 95-100°C for 150-180 minutes, crushed, and wire-drawn; fried once after being mixed with seasoning; The second frying, adding edible oil in the second frying; cooling and packaging after being out of the pan, and the finished product is obtained; it is characterized in that the addition of edible oil in the second frying is to use edible oil mist spraying equipment to add 120-150 ° C , Mist edible oil with a particle size of 50-500 μm.

[0041] The one-time frying includes the following steps: initial frying at a temperature of 100-120°C for 60-80 minutes; after loosening, frying at a temperature of 150-180°C for 40-80 minutes, after the moisture content of the dried meat floss is 20-25%. Let cool.

[0042] The secondary frying is frying at a temperature of 200-240° C. for 20-40 minutes, spraying mist edible oil when the...

Embodiment 3

[0045] A method for making meat floss, which comprises the following steps: fresh fish meat is sorted and cut into pieces, steamed for 150-180 minutes at a temperature of 95-100° C., crushed, and wire-drawn; fried once after being mixed with seasoning; fried twice after cooling Cooking, adding edible oil in the second frying; cooling and packaging after being out of the pan, and then obtaining the finished product; it is characterized in that, adding edible oil in the second frying is to use edible oil mist spraying equipment to add 120-150 ° C, granular Mist edible oil with a diameter of 50-500 μm.

[0046] The one-time frying includes the following steps: initial frying at a temperature of 100-120°C for 60-80 minutes; after loosening, frying at a temperature of 150-180°C for 40-80 minutes, after the moisture content of the dried meat floss is 20-25%. Let cool.

[0047] The secondary frying is frying at a temperature of 200-240° C. for 20-40 minutes, spraying mist edible oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com