Lentinula edodes drying mechanism

A technology for drying mechanism and shiitake mushrooms, applied in application, food processing, food science, etc., can solve the problems of insufficient drying and uneven heating of shiitake mushrooms, and achieve strong deformation irreversibility, enhanced flexibility, and good drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific embodiments,

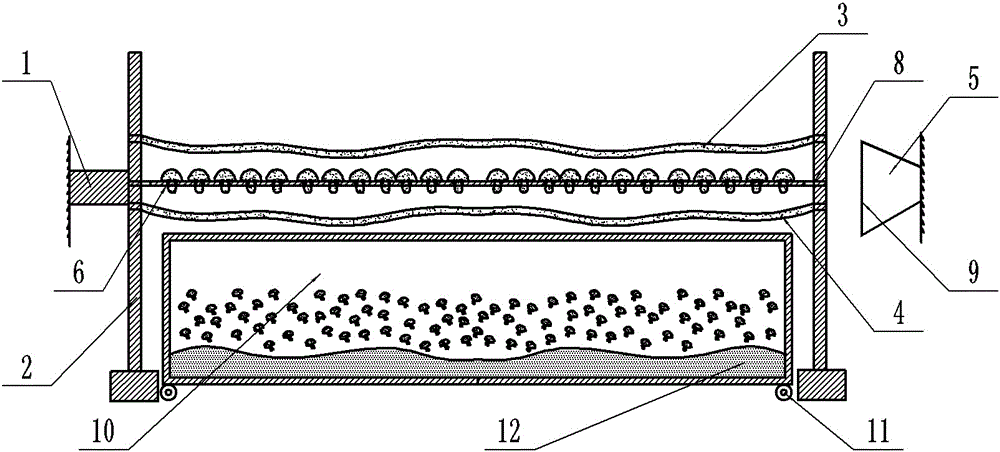

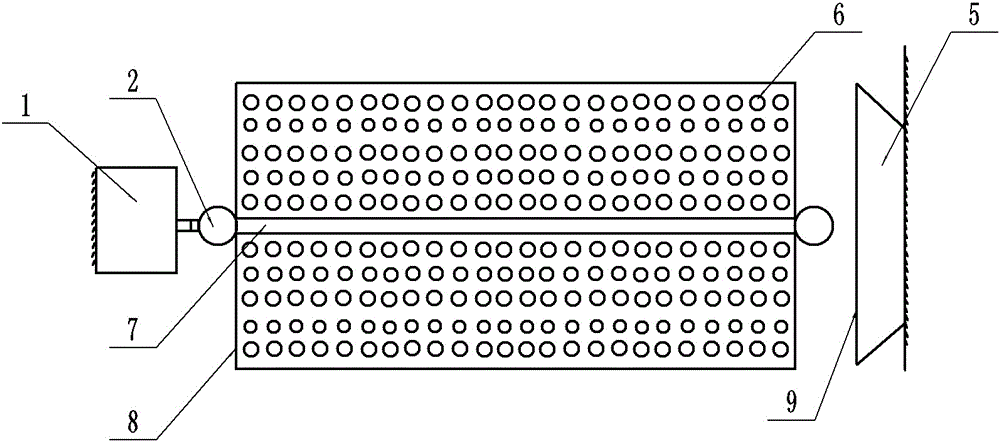

[0018] The reference signs in the accompanying drawings of the specification include motor 1, support column 2, first tin foil layer 3, second tin foil layer 4, drying fan 5, mushroom port 6, rotating shaft 7, drying rack 8, blowing port 9. Collection frame 10, universal wheels 11, drying layer 12.

[0019] Embodiment The shiitake mushroom drying mechanism is basically as attached figure 1 And attached figure 2 As shown, it includes a control mechanism, a motor 1 and a frame, and also includes two supporting columns 2, two tinfoil layers, a vibrator and a drying fan 5, and the tinfoil layer includes an elastic net and tinfoil paper on the elastic net, two pieces The tin foil layer is an upper tin foil layer and a lower tin foil layer, and an upper tin foil layer, a drying rack 8 and a lower tin foil layer are respectively arranged between the two support columns 2 from top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com