Carbon strong kneading cylinder body

A kneading and cylinder technology, which is applied to mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of large installation space, impossibility of use, poor kneading effect, etc., and achieve smooth feeding process and increased The area of heat exchange and the effect of improving the kneading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

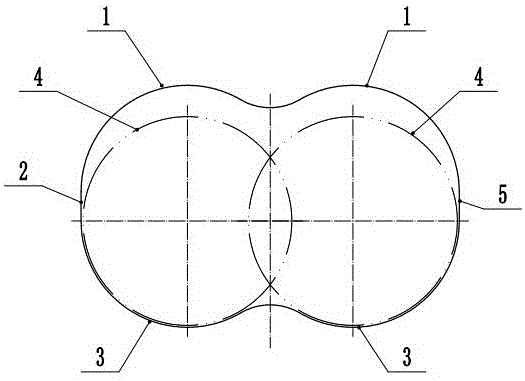

[0019] Such as figure 1 , a carbon strong mixing and kneading cylinder body, each of the left and right mixing knives 4 is installed in the cylinder body, and the axes of the mixing knives 4 are all moving forward and backward, and are used to stir the paste;

[0020] The cross-sectional profile of the inner wall of the cylinder in the front-back direction includes an upper extrusion kneading arc section located above the mixing knife 4 and a lower extrusion kneading arc section located below the mixing knife 4;

[0021] The upper extrusion kneading arc section is provided with two concave upper arc sections 1 corresponding to the two mixing knives 4 one by one;

[0022] The lower extrusion kneading arc section is provided with two concave lower arc sections 3 corresponding to the two mixing knives 4 one by one.

[0023] The gap between the upper arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com