Catalytic reaction tank for sewage treatment

A catalytic reaction and sewage treatment technology, which is applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of catalyst and sewage affecting reaction efficiency, easy enrichment, and inapplicability. , to achieve the effect of convenient and full mixing, improving reaction efficiency, convenient collection and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

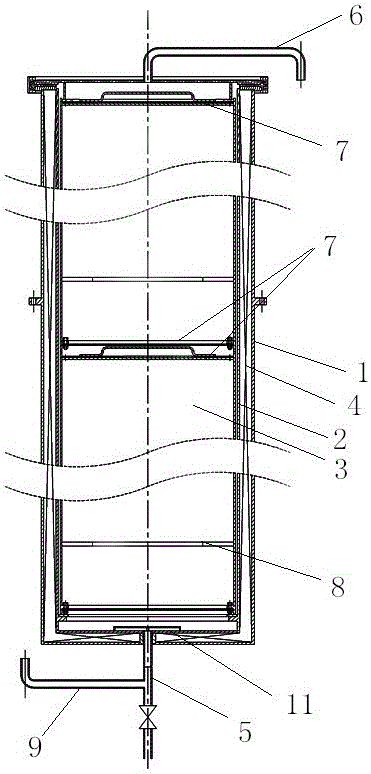

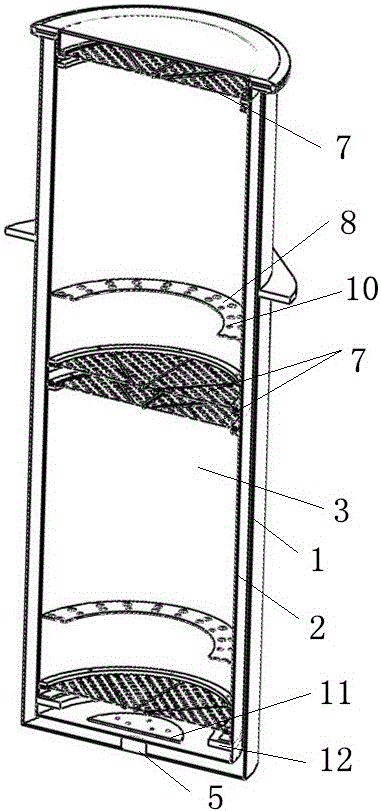

[0016] Embodiment 1: as figure 1 with 2 Shown is a catalytic reaction tank for sewage treatment, the catalytic reaction tank is a cylindrical cylinder structure, the cylinder structure is composed of a cylindrical shell 1 and a cylindrical inner tank 2, An insulating layer 4 is provided between the shell 1 and the inner tank 2, the top of the cylinder is provided with a discharge pipe 6, and the bottom of the cylinder is provided with a feed pipe 5, and the inner tank 2 is movable and installed with multiple Catalyst reaction barrel 3, described catalyst reaction barrel 3 is made up of upper and lower two circular screen mesh end faces 7 and cylindrical barrel wall, and the diameter of barrel wall matches the inner diameter of liner 2, and described catalytic reaction An annular baffle 8 is provided on the inner wall of the barrel 3, and a plurality of longitudinally installed baffle flow holes 10 are evenly distributed on the baffle 8.

Embodiment 2

[0017] Embodiment 2: as figure 1 with 2 As shown, the feed pipe 5 is provided with a feed valve and a branch pipeline 9, and the branch pipeline 9 is an emptying pipe; after the overall reaction is completed, the catalyst reaction barrel 3 is taken out from the inner tank 2, and the inner tank is The residual liquid in 2 needs to be emptied through the emptying pipe 9 to facilitate the cleaning and maintenance of the inside of the tank.

Embodiment 3

[0018] Embodiment 3: as figure 1 with 2 As shown, the bottom of the liner 2 is provided with a circular flow divider 11, the bottom of the flow divider 11 is connected to the feed pipe 5, and the top of the flow divider 11 is provided with a plurality of flow openings; The bottom of the barrel 3 is connected to facilitate sufficient contact between the sewage and the catalyst stored in the catalytic reaction barrel 3 and improve the reaction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com