A waste glass recycling system

A waste glass and drum technology, applied in the field of recycling systems, can solve the problems of poor environmental protection effect and unsafety of waste glass, and achieve the effects of shortening melting time, strong pertinence and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

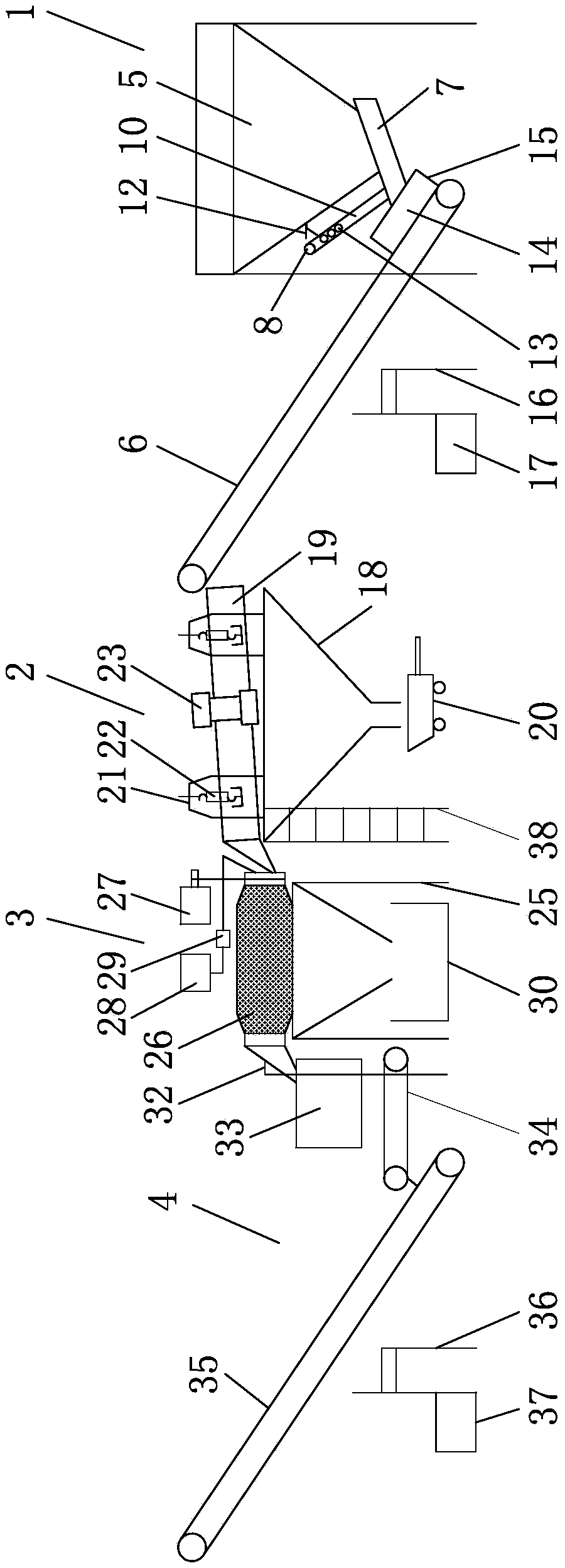

[0022] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

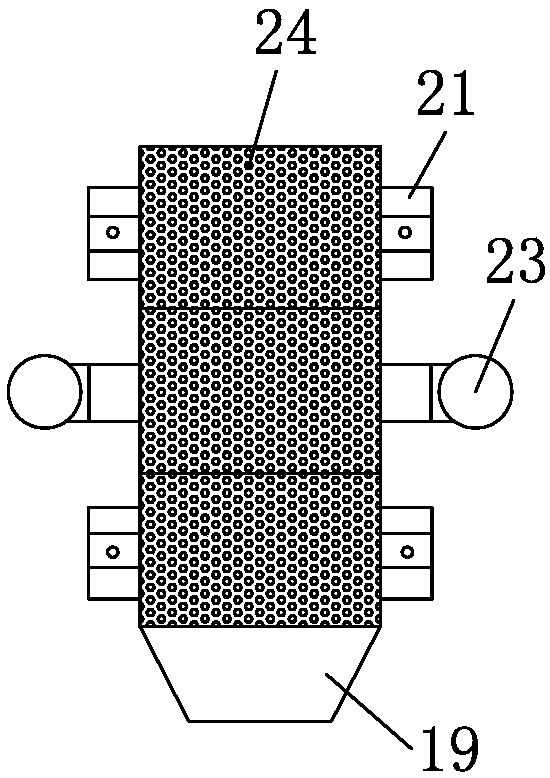

[0023] like figure 1 As shown, the present invention is provided with a feeding mechanism 1, a screening mechanism 2, a cleaning mechanism 3 and a crushing and conveying mechanism 4. The feeding mechanism 1 transfers the collected waste glass to the screening mechanism 2 for screening, and the finely divided impurities are After screening, it enters the cleaning mechanism 3 for cleaning, and finally enters the crushing and conveying mechanism 4 for crushing and transports to the designated area.

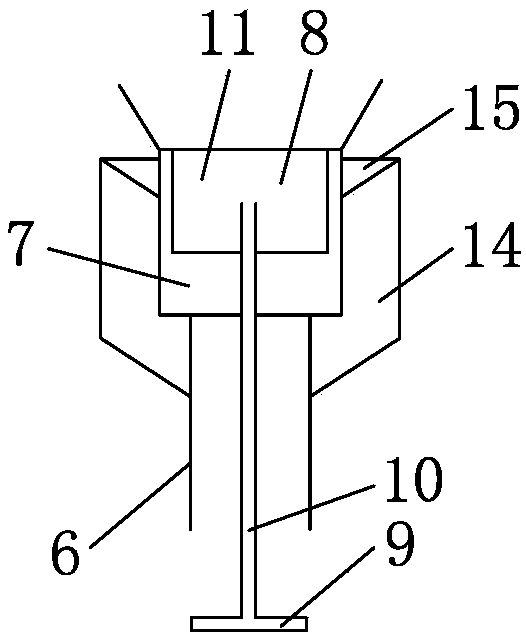

[0024] The feeding mechanism 1 is provided with a feeding chute 5 and a feeding conveyor belt 6, and the waste glass in the feeding trough 5 falls onto the feeding conveyor belt 6 for transmission. The bottom of the feeding chute 5 is provided with an opening, and the opening is fixedly connected with an inclined guide groove 7, which can smoothly gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com