A graphite lithium battery negative electrode material crushing and collecting device

A negative electrode material and collecting device technology, which is applied in the field of graphite lithium battery negative electrode material pulverizing and collecting device, can solve the problems of long pulverization time, processing, poor pulverizing effect of pulverizer, etc., and achieve the effect of improving effect and efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

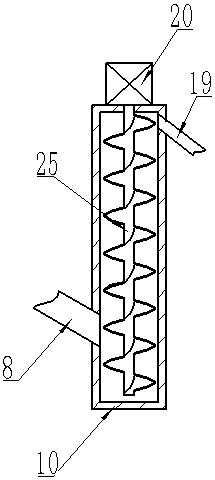

[0022] See Figure 1-5 , A graphite lithium battery negative electrode material crushing collection device, including a primary feeding crushing and feeding device and a secondary crushing receiving device; the primary feeding crushing and feeding device includes a first motor 1, a drive shaft 2, and a left carrier plate 3. Left support frame 4, crushing runner 5, rotating shaft 6, primary crushing box 7, first guide box 8, base 9, loading box 10, second guide box 19, third motor 20, The second connecting plate 21, the feeding cylinder 22, the bearing seat 23, the transmission belt 24 and the screw rod 25; the left support frame 4 is welded on the left side of the base 9; the left carrier plate 3 is welded on the left support frame 4; The first motor 1 is fixedly arranged on the left carrier plate 3; the transmission shaft 2 is fixedly arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com