Steel wire rope oil stain cleaning device for fixed winding headstock gear

A technology of oil stain removal and hoist, which is applied to the device for coating liquid on the surface, the cleaning method and utensils, the cleaning method using tools, etc., which can solve the problem of unfavorable new butter application, the effect of rag degreasing is not obvious, and the influence of wire rope Use and other problems to achieve the effect of improving the cleaning effect, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

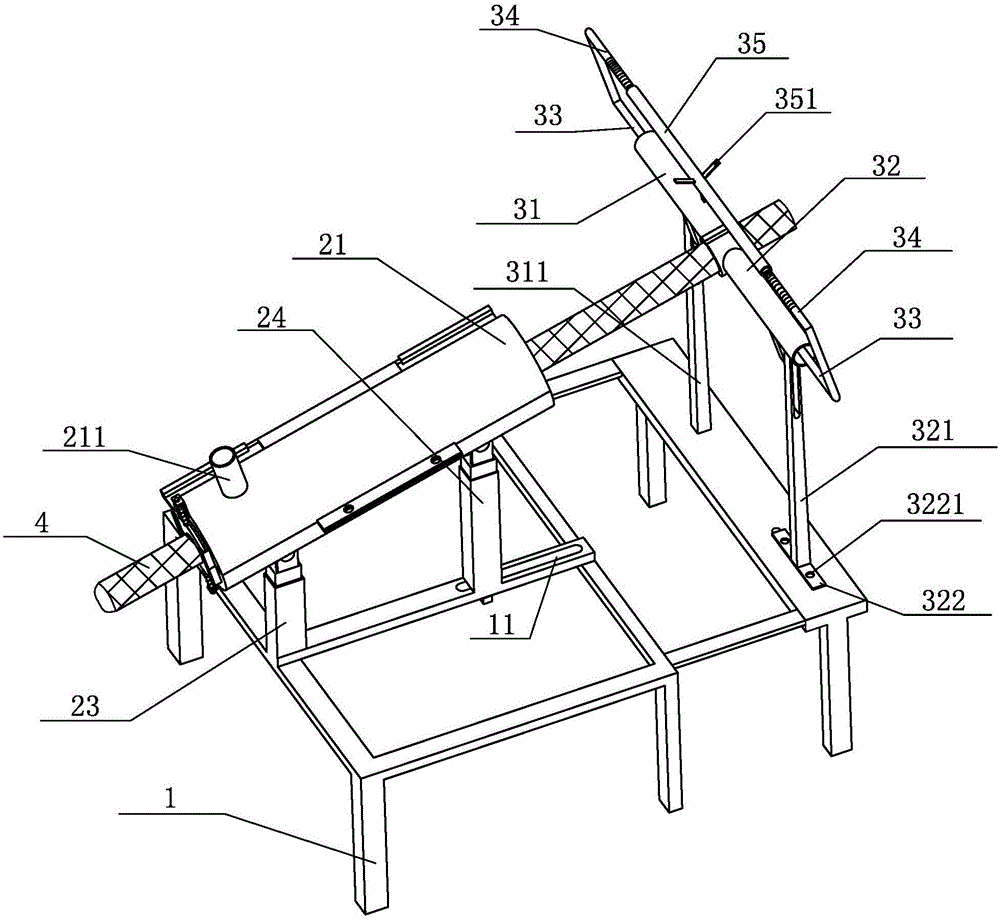

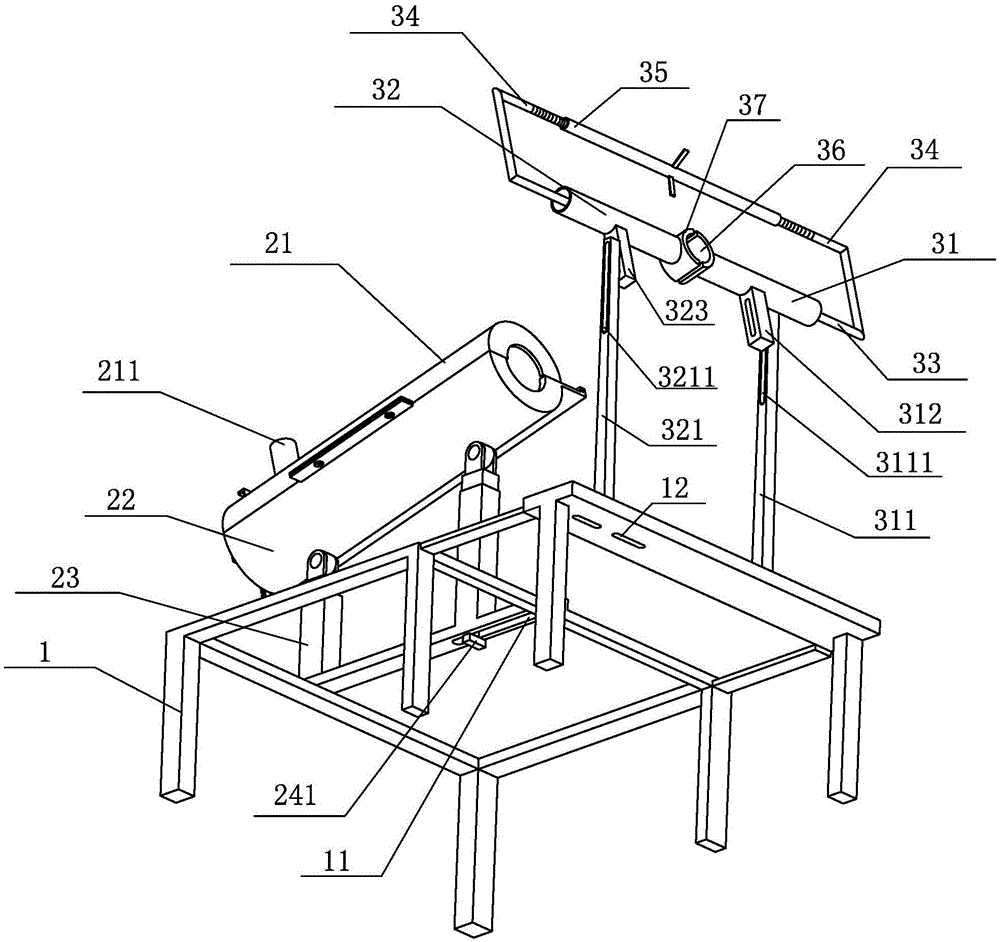

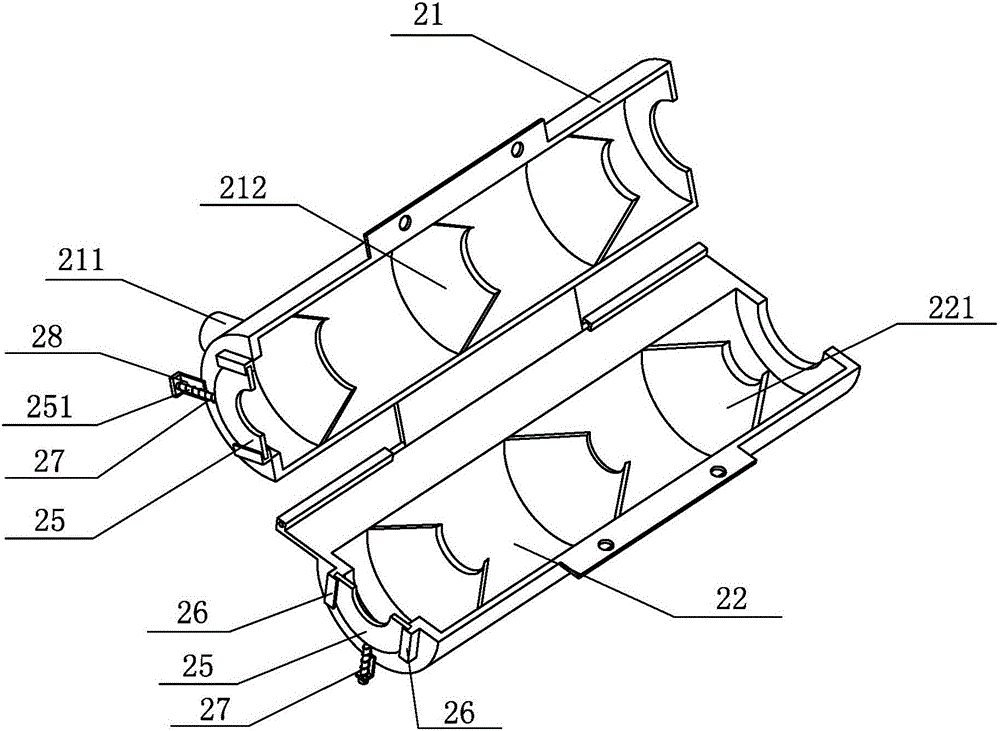

[0018] The following will combine specific embodiments and appendixes Figure 1-5 , clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the preferred embodiments of the present invention, rather than all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0019] The invention provides a fixed type hoisting hoist wire rope oil pollution removal device (such as figure 1 shown), including a bracket 1, a degreasing mechanism and an oiling mechanism, the degreasing mechanism includes an upper arc-shaped casing 21, a lower arc-shaped casing 22 and a small hot air blower (in order to keep the drawings clear, in the accompanying drawings It is not shown), the small hot air blower is a mature product on the mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com