Rolling mill laminar flow uniform cooling nozzle

A uniform cooling and nozzle technology, which is applied in the workpiece cooling device, metal rolling, metal rolling, etc., can solve the problems of insufficient spraying force, poor cooling effect, waste of cooling cost, etc., to achieve small flow path resistance, Simple structure and reduced cooling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

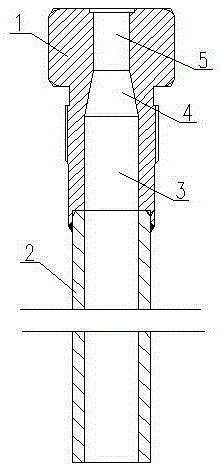

[0012] A laminar flow uniform cooling nozzle for a rolling mill, comprising a nozzle 1 and a flow channel connection 2, the rear end of the nozzle 1 is fixedly installed on the front end of the flow channel connection 2, the nozzle channel is connected with the flow channel connection channel, and the nozzle channel is divided into Rear passage 3, transition passage 4 and injection passage 5, the inner diameter of rear passage 3 is greater than the diameter of injection passage 5, and described transition passage 4 is a tapered passage, and the inner diameter of nozzle passage is identical with the inner diameter of flow path connection passage; There is a step in the end, and the front end of the flow channel joint is located at the step; the inner wall of the nozzle channel and the inner wall of the flow channel connection channel are smooth surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com