Manufacturing method for high-strength and high-precision small taper angle part

A manufacturing method and high-precision technology, applied in the field of precise plastic processing, can solve the problems of high risk of product use, weakening of weld strength, cumbersome weld inspection, etc., to overcome the risk of injury, improve product quality, and product consistency. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

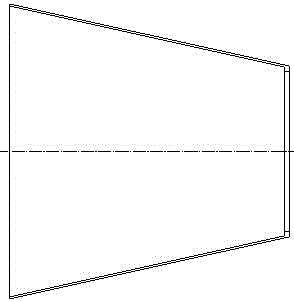

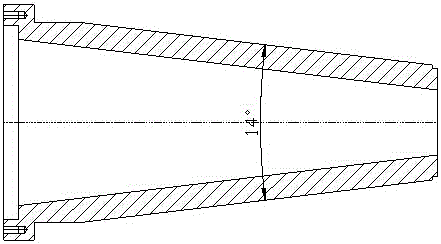

[0028] This embodiment takes the manufacturing method of a small cone angle part as an example, and elaborates in detail the core technical issues of using the spinning process to obtain this type of part. The material of the target product in this embodiment is 5A06, and the structural size is as follows figure 1 As shown, the wall thickness requirement δ=2.5±0.05mm, the strength requirement σs≥309Mpa, σb≥417MPa. Generally speaking, the product precision requirement is high, and the product strength is also much higher than the index of the base material tensile strength 315Mpa.

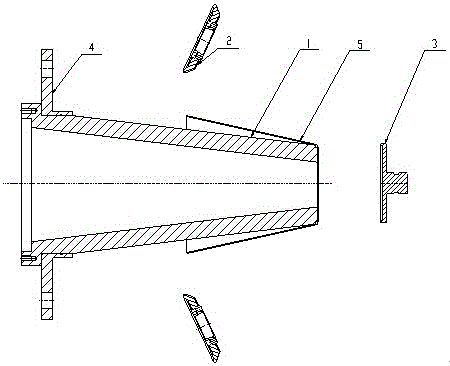

[0029] The processing scheme determined in this embodiment is "machining (forging billet)-spinning-machining (finished product)". Among them, the supply status of purchased forging blanks is 5A06-O, and the raw material standards are implemented in accordance with GJB2351-1995.

[0030] After machining the forging blank, the blank before spinning is obtained such as figure 2 As shown, the design...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com