Casting method for beam guard plate of gyratory crusher

A crusher and gyratory technology, which is used in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as affecting the appearance quality of beam guard castings, time-consuming and laborious manual grinding, and shortening of riser residual time. The effect of quality assurance, labor cost reduction and feeding efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

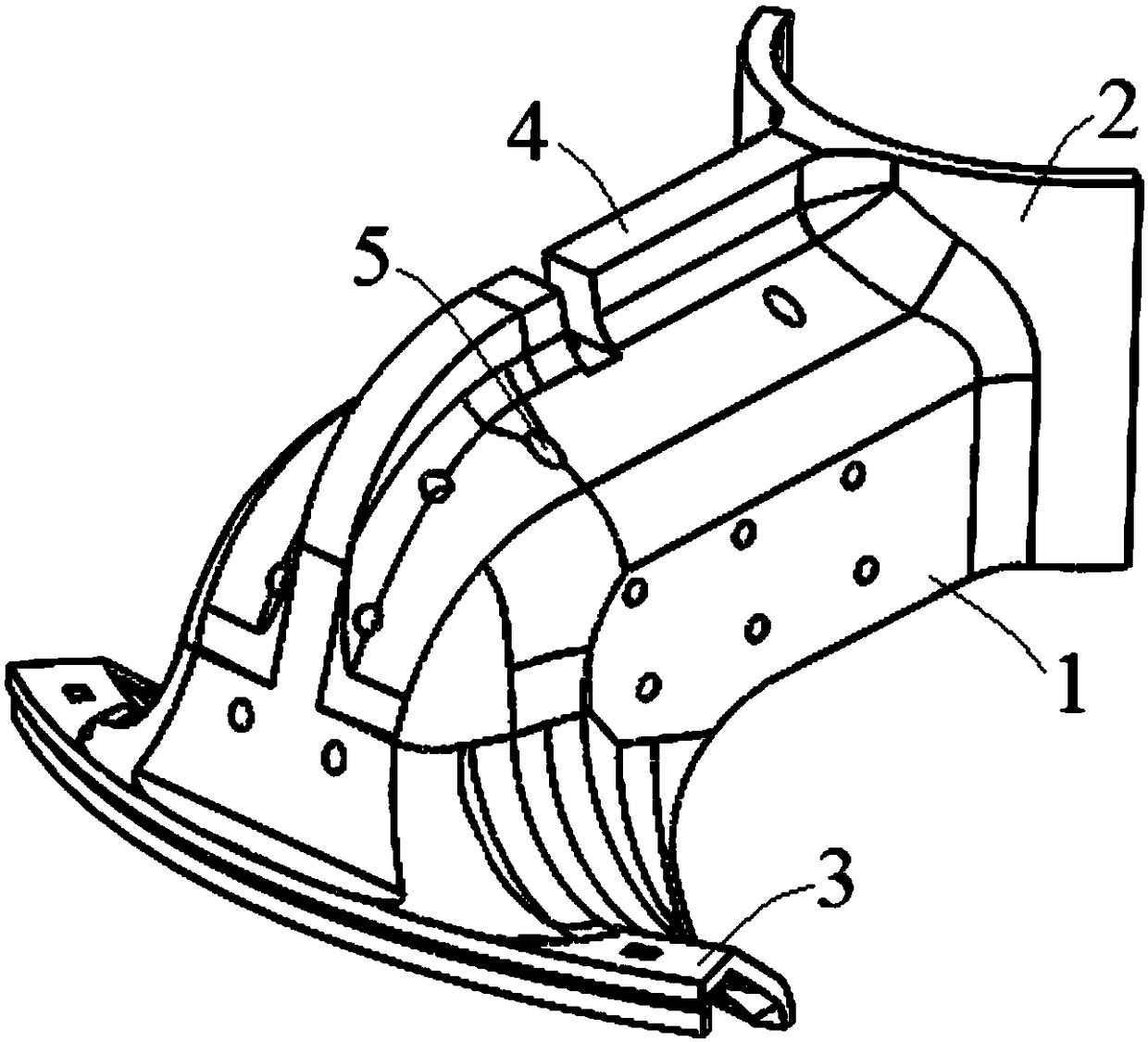

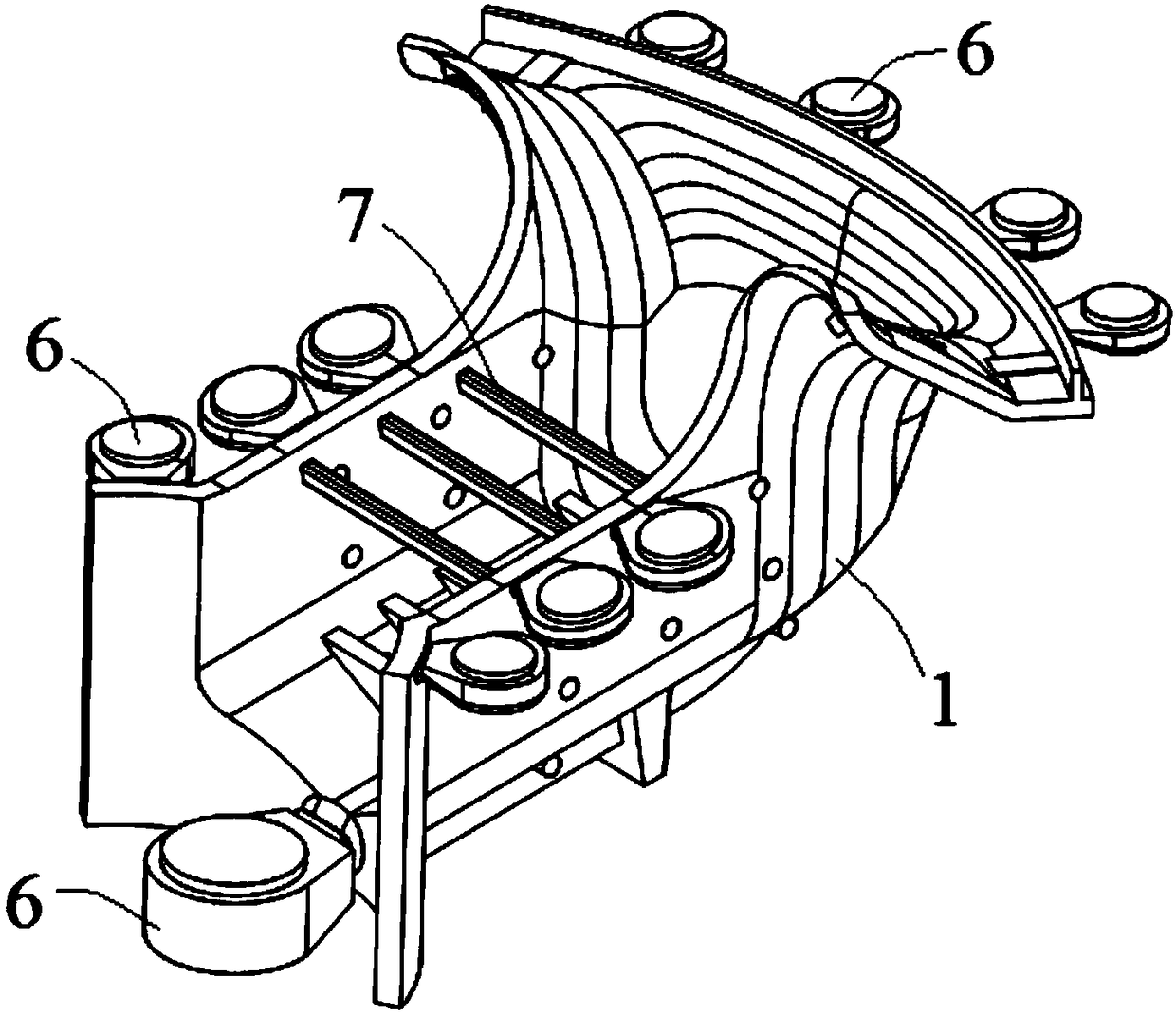

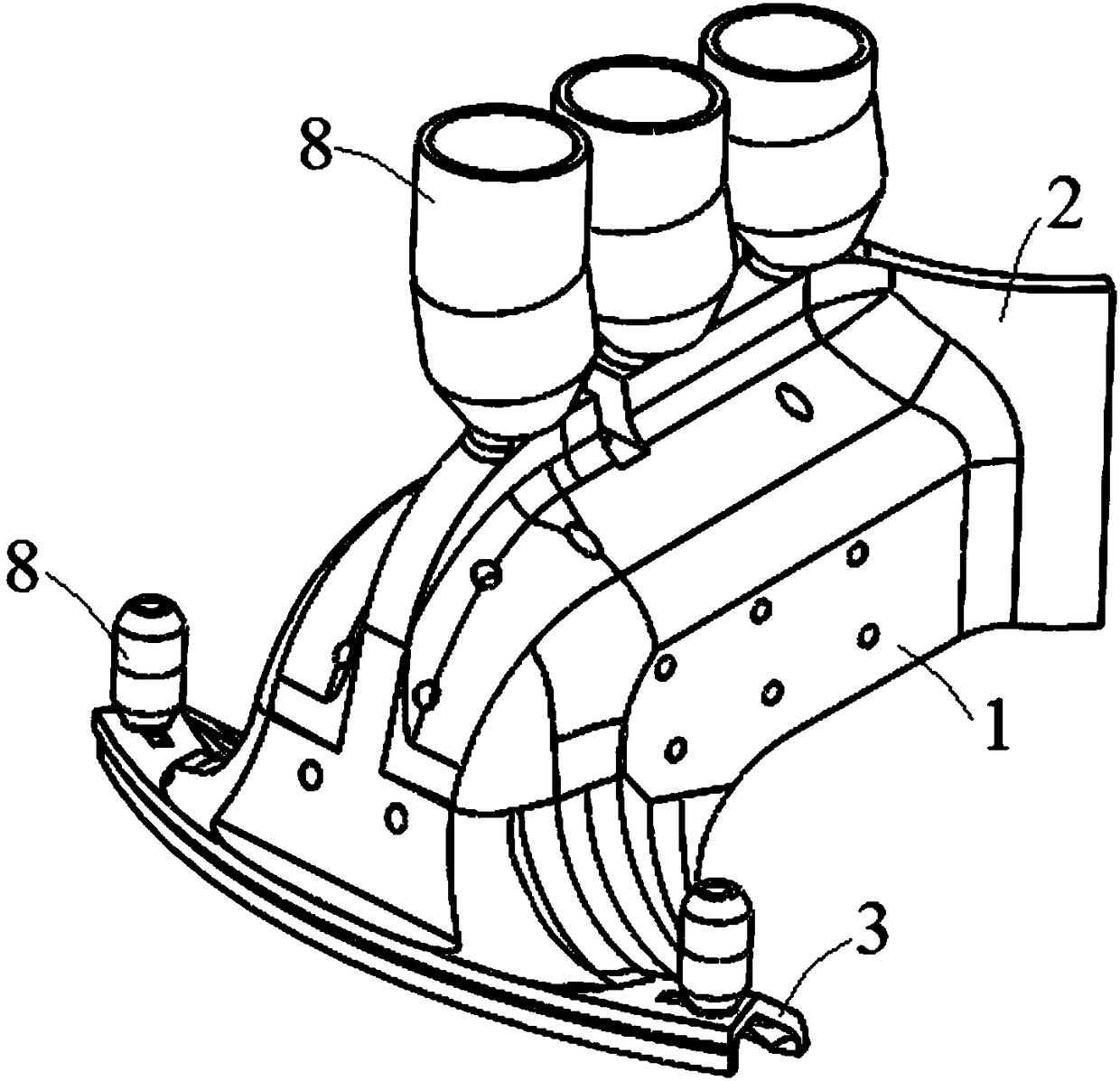

[0042] In order to overcome the upside-down casting process of the beam guard plate of the traditional gyratory crusher, there are many residual risers, which affect the appearance quality of the beam guard plate casting, and manual grinding is time-consuming and laborious. It is necessary to feed the high-position riser to the low-position riser, resulting in waste of molten steel. Problem, this embodiment provides a casting mold for the beam guard plate of a gyratory crusher, which includes an internal sand core and an external sand mold, and a cavity is formed between the sand core and the sand mold. Compared with the traditional process, this embodiment uses the beam guard plate Turn the direction and change it to face-on casting, and the sand mold is designed to be placed face-to-face according to the pouring position of the beam guard plate. Among them, the normal use state of the beam guard plate is the so-called positive position, such as figure 2 The state shown is t...

Embodiment 2

[0056] The casting mold and casting method of a gyratory crusher crossbeam guard plate in this embodiment are basically the same as in Embodiment 1, the difference is that the height ratios of the sand mold monomers L1, L2 and L3 in the vertical direction in this embodiment It is 1:2.3:1.2.

Embodiment 3

[0058] The casting mold and casting method of a gyratory crusher crossbeam guard plate in this embodiment are basically the same as in Embodiment 1, the difference is that the height ratios of the sand mold monomers L1, L2 and L3 in the vertical direction in this embodiment It is 1:2.1:1.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com