3D printing method for selective deposition of uniform metal droplets

A 3D printing and uniform technology, which is applied in the field of 3D printing of uniform metal droplet selective deposition, can solve the problems of poor printing accuracy, improve stability and printing accuracy, avoid the accumulation of heat and thermal stress, reduce deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

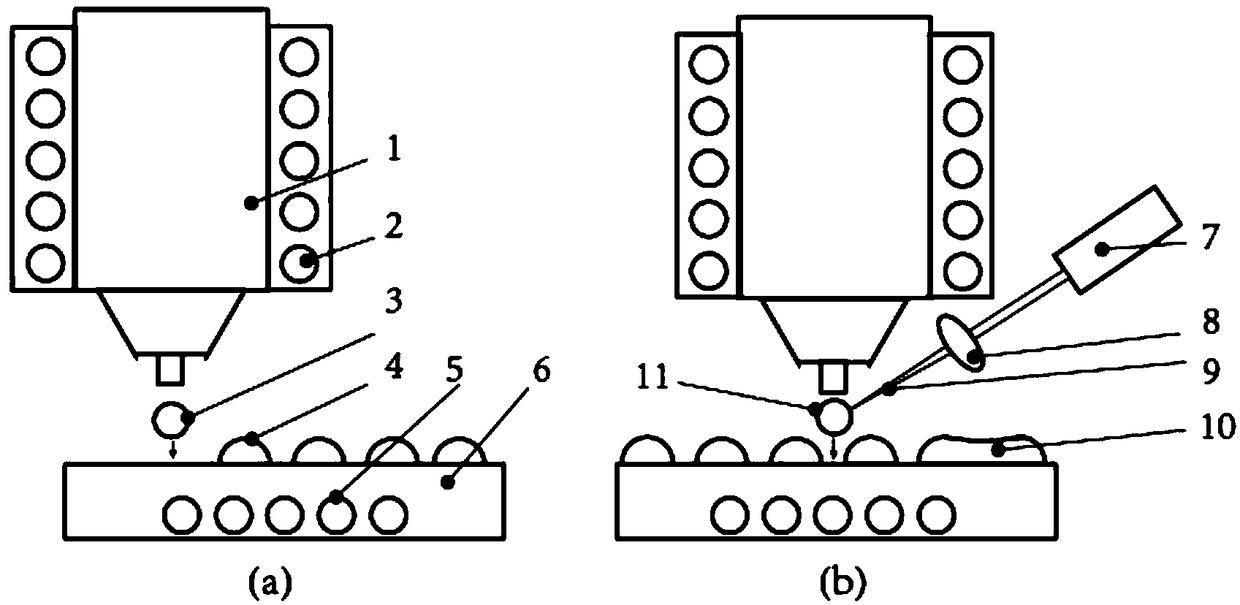

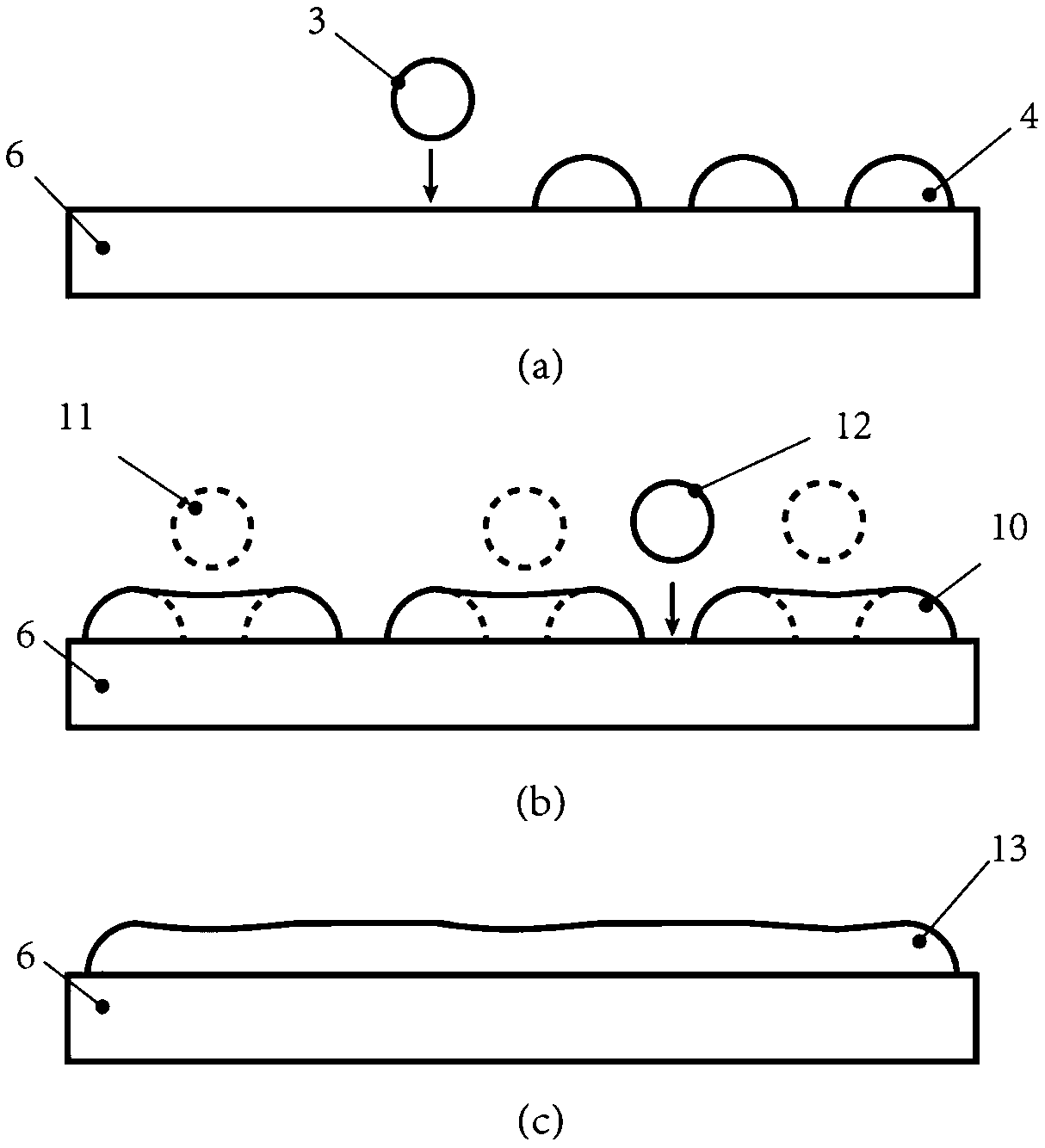

[0019] Embodiment 1: refer to figure 2 , using the 3D printing method of selective deposition of uniform metal droplets to print metal wires with smooth surface and accurate size on the substrate. When printing a shaped metal wire, it is first necessary to print uniform metal droplets 3 with a lower temperature. The substrate heating device 5 and the droplet ejection heating device 2 are turned on, and the substrate 6 and the uniform droplet ejection device 1 are heated to a predetermined temperature. Afterwards, adjust the temperature of the uniform droplet ejection device 1 and the temperature of the substrate 6, use the uniform droplet ejection device 1 to print uniform metal droplets 3, and print out A row of uniform metal micro-droplets 3 is deposited and spread until the uniform metal micro-droplets 3 are cooled and solidified, thereby forming metal bumps 4 in an array at equal intervals. Then, the relative position between the substrate 6 and the uniform droplet ejec...

Embodiment 2

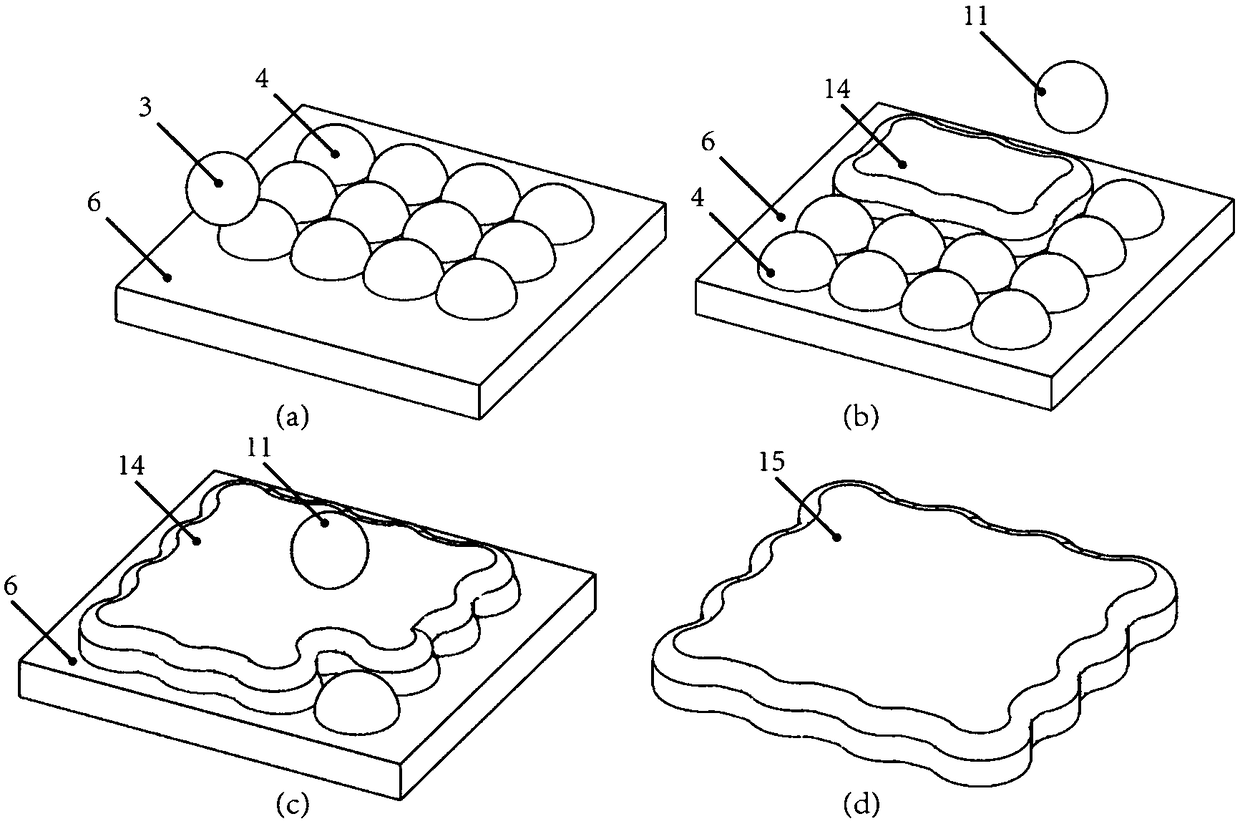

[0020] Embodiment 2: refer to image 3 , using the 3D printing method of selective deposition of uniform metal droplets to print a metal sheet with a smooth surface and accurate dimensions on the substrate. When printing and forming a thin metal plate, it is first necessary to print uniform metal droplets 3 with lower temperature on the substrate 6 in the form of row by row and column by column with equal spacing under the condition of optimal droplet spacing, thereby forming The metal bumps 4 on the array, this process is basically the same as the steps in the method embodiment 1. Afterwards, adjust the relative position between the substrate 6 and the uniform droplet ejection device 1 , and position it in the middle of the intersecting gap between every two rows of metal bumps 4 and every two rows of metal bumps 4 . At this time, the pulse laser 7 is turned on and synchronized with the uniform droplet ejection device 1. After the laser beam 9 is focused by the lens 8, it ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com