Photoinduced reversible solid-liquid conversion azobenzene high polymer material and application thereof in trenchless pipeline repair

A polymer material and solid-liquid transformation technology, applied in the field of pipeline repair, can solve the problems that cannot be repaired again, cross-linked polymers cannot be melted or dissolved, and achieve a good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

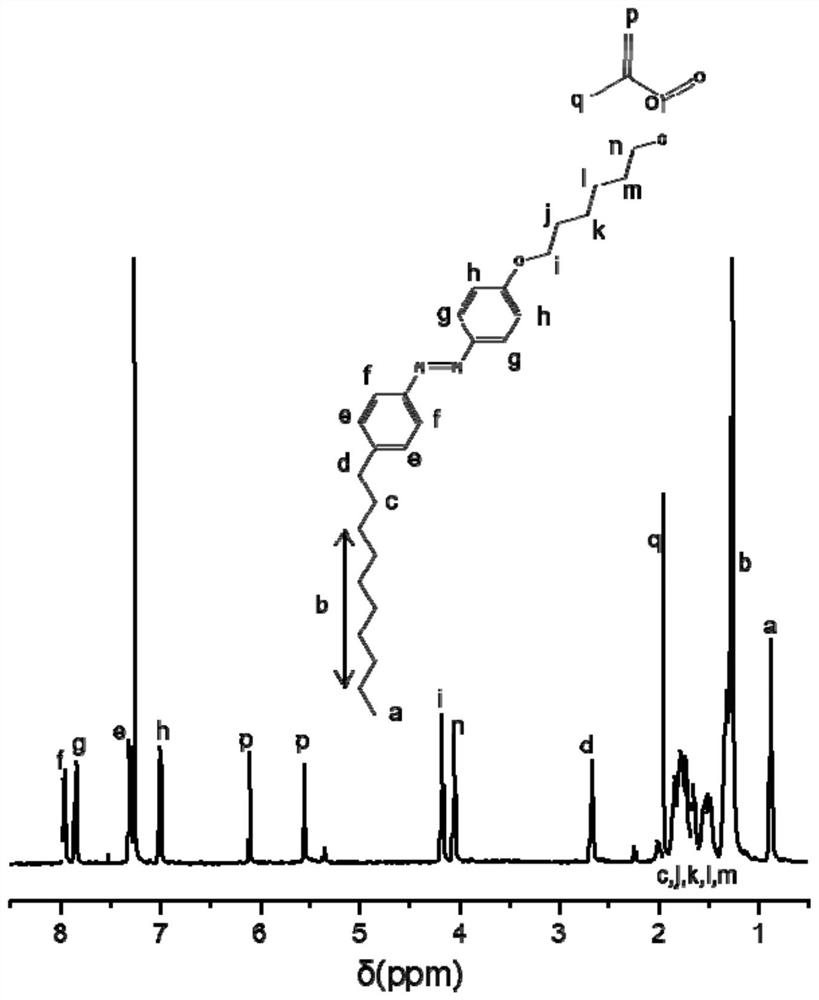

[0032] Embodiment 1: the synthesis of polymerization monomer

[0033]

[0034] 1. 4-n-decylaniline (10g, 42.8mmol) was added to a mixed solution of dilute hydrochloric acid (11.0ml, ρ=1.18g / ml, 128.8mmol) and tetrahydrofuran (40ml), then placed in an ice-water bath. After stirring evenly, an aqueous solution of sodium nitrite (2.950 g, 42.8 mmol) was slowly added thereto, and mixed for 20 min. Phenol (4.6 mL, 1.071 g / ml, 49.5 mmol) was dissolved in an aqueous solution of sodium hydroxide (1.7 g, 43.0 mmol) and potassium carbonate (6.0 g, 43.4 mmol), and stirred for 20 min. The mixed solution containing 4-n-decylaniline was slowly added dropwise to the mixed solution containing phenol to react, the solution gradually changed from yellow to brown, and stirred at room temperature for 4 h. Neutralize to pH=6 with dilute hydrochloric acid, filter with suction, and wash with water three times to obtain a yellow-brown solid. Vacuum-dried at 45°C overnight, thermally recrystalliz...

Embodiment 2

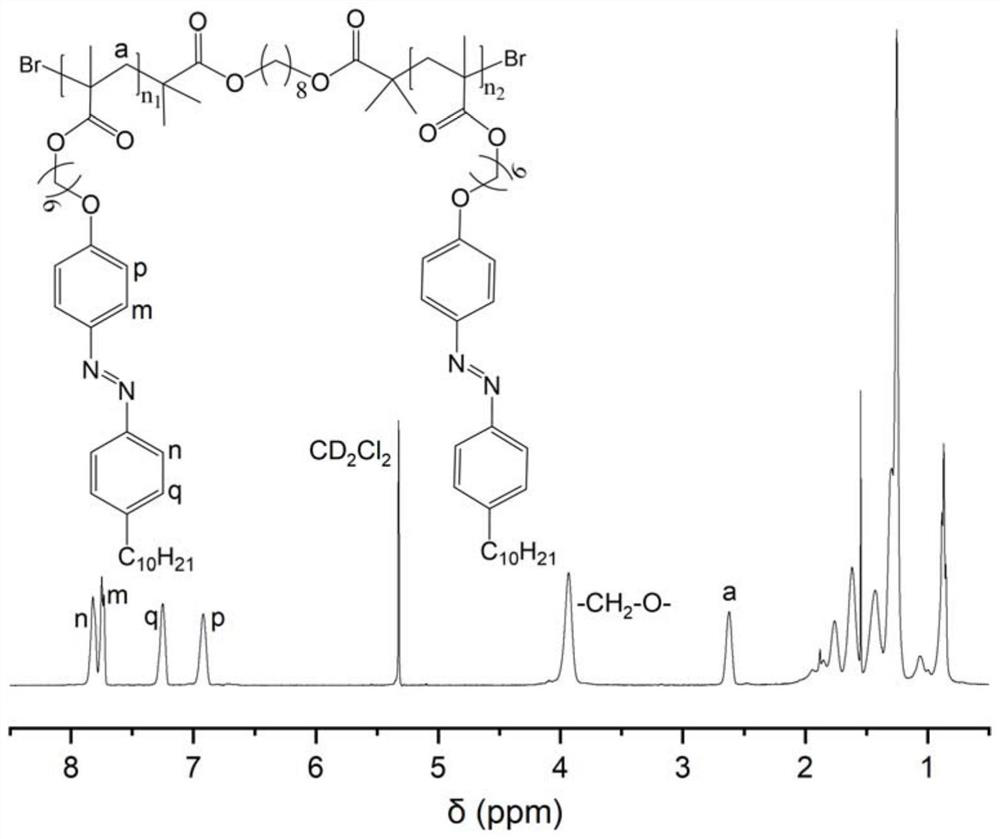

[0038] Embodiment 2: Polymerization of azobenzene macromolecule

[0039] Dissolve 1,8-octanediol (1.65g, 11.3mmol) in 80mml of dichloromethane solvent, then add triethylamine (8.2mL, 58.9mmol) to it, stir well, and cool to 5°C in an ice-water bath Below; through the dropping funnel, add 2-bromoisobutyryl bromide (7ml, 56.5mmol) in this solution with the speed of 3s / drops, white mist is produced in the dropping process, and temperature rises slightly. After the dropwise addition, seal the mouth of the bottle with parafilm and continue to stir overnight for 12h. Extract three times with dichloromethane (lower layer) and saturated aqueous sodium chloride, and collect the organic phase. Dry with anhydrous sodium sulfate to remove water, filter, and remove solvent by rotary evaporation at 40°C. Pass through a silica gel column, and the eluent is petroleum ether:dichloromethane 100:0-4:1. Vacuum-dry at 45°C for 4 hours to obtain 1.8g of initiator.

[0040] Take the monomer 6-(4-((...

Embodiment 3

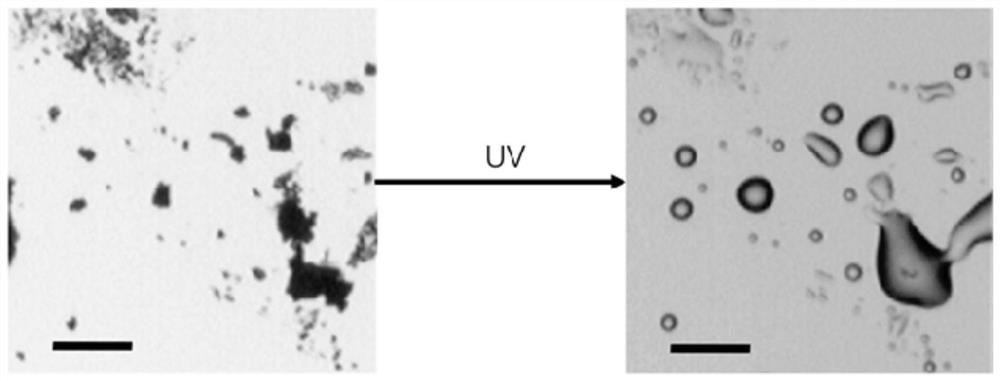

[0041] Example 3: Photo-induced solid-liquid transition of azobenzene polymers at the micron scale

[0042] At room temperature, take a small amount of azobenzene macromolecule (embodiment 2) solid sample on a smooth and clean glass slide, put the glass slide on the stage of the microscope, and use 365nm (5.5mW / cm 2 ) ultraviolet light irradiates the surface of the solid sample to cause photoisomerization, and after 15 minutes of irradiation, a complete solid-liquid transition is achieved. image 3 Liquefaction of trans solid samples under UV light irradiation is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com