Epoxy resin polymer cement and preparation method thereof

A technology of epoxy resin and polymer glue, applied in the direction of filling slurry, etc., can solve the problems of reducing the effective time of epoxy glue filling effect, decreasing bonding stability, poor fluidity, etc., to accelerate expansion and improve volume expansion. efficiency, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

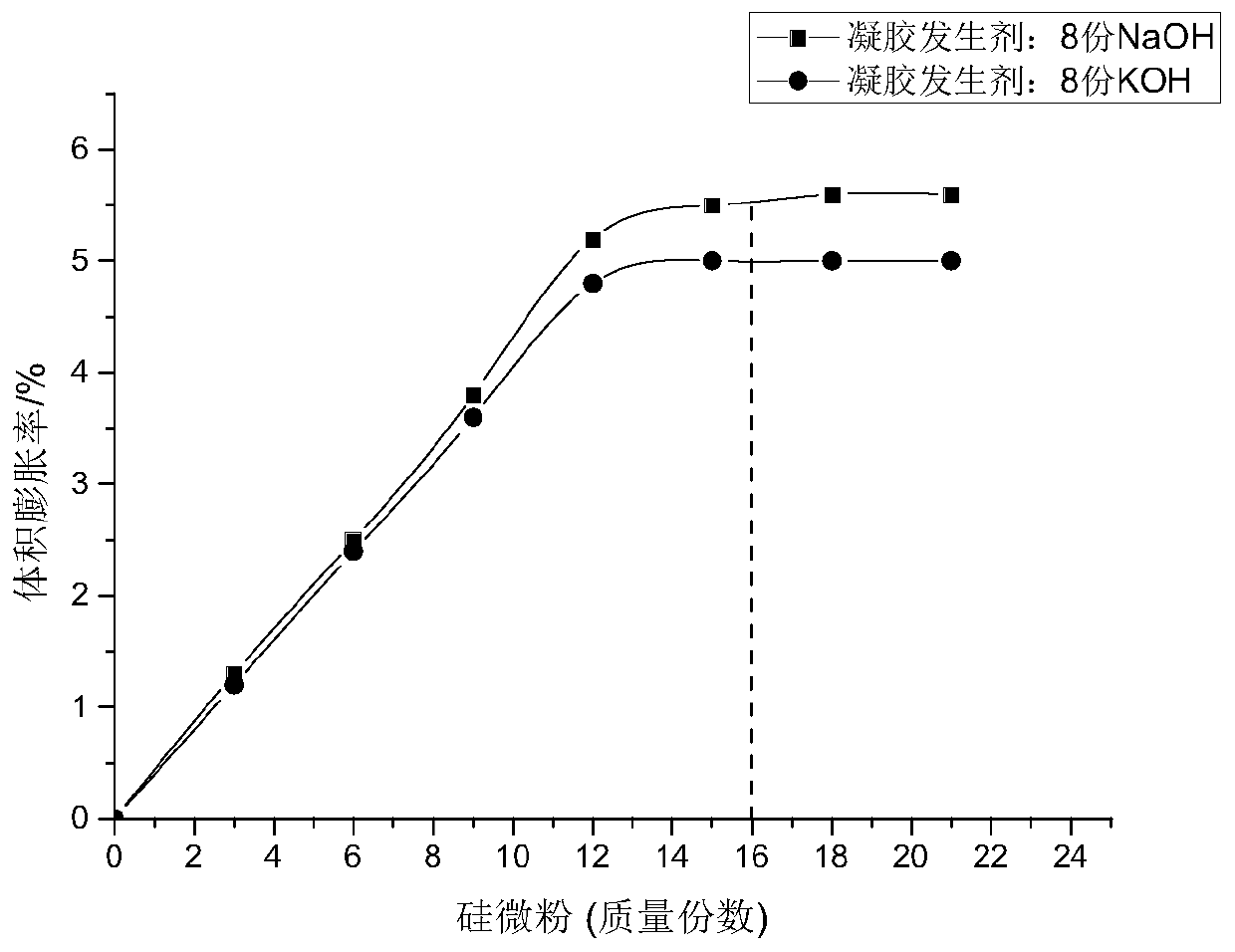

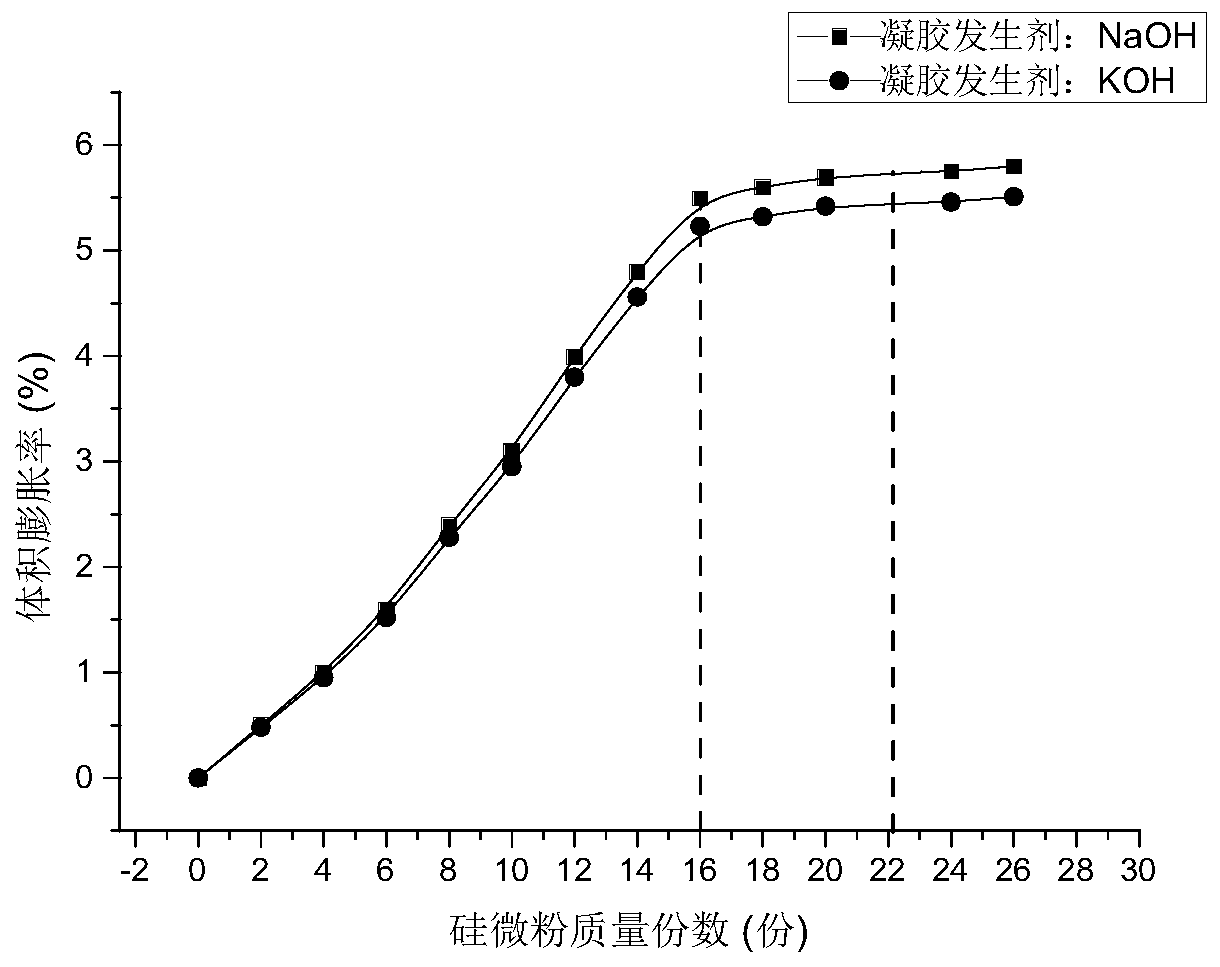

[0051] Preparation of S1 composition A: add 100 parts of bisphenol A epoxy resin and 16 parts of microsilica powder (1250 mesh) into a mixer according to the ratio of parts by mass, and stir for 10-12 minutes, and stir evenly to obtain composition A;

[0052] S2 Preparation of composition B: mix 100 parts of ketimine and 8 parts of gel generating agent (NaOH) according to the mass parts and add them into another mixer and stir for 10-12 minutes, and stir evenly to obtain composition B;

[0053] S3 Mixing configuration: The ratio of composition A and composition B is measured as 1:1 by weight, and composition A and composition B are added to the mixer at a stirring speed of 100r / min, and the epoxy resin polymer cement is obtained after stirring for 4-5 minutes .

[0054] Wherein the proportion of composition A and composition B is 1:0.8-1.2 by weight, which is convenient for actual preparation and use on the spot, and reduces calculation, and this is selected as 1:1.

Embodiment A2

[0056] Preparation of S1 composition A: add 100 parts of bisphenol A epoxy resin and 16 parts of microsilica powder (1250 mesh) into a mixer according to the ratio of parts by mass, and stir for 10-12 minutes, and stir evenly to obtain composition A;

[0057] S2 Preparation of composition B: mix 100 parts of ketimine and 8 parts of gel generating agent (select KOH) according to the mass parts and add them into another mixer and stir for 10-12 minutes, and stir evenly to obtain composition B;

[0058] S3 Mixing configuration: The ratio of composition A and composition B is measured as 1:1 by weight, and composition A and composition B are added to the mixer at a stirring speed of 100r / min, and the epoxy resin polymer cement is obtained after stirring for 4-5 minutes .

Embodiment A3

[0060] Preparation of S1 composition A: add 100 parts of bisphenol A epoxy resin and 16 parts of microsilica powder (1250 mesh) into a mixer according to the ratio of parts by mass, and stir for 10-12 minutes, and stir evenly to obtain composition A;

[0061] S2 Preparation of composition B: mix 100 parts of ketimine, 4 parts of NaOH, and 4 parts of KOH according to the mass parts and add them into another mixer and stir for 10-12 minutes, and stir evenly to obtain composition B;

[0062] S3 Mixing configuration: The ratio of composition A and composition B is measured as 1:1 by weight, and composition A and composition B are added to the mixer at a stirring speed of 100r / min, and the epoxy resin polymer cement is obtained after stirring for 4-5 minutes .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com