A kind of machine clip cutting knife and its processing method

A processing method and cutting knife technology, applied in metal processing equipment, manufacturing tools, accessories of toolholders, etc., can solve the problems of affecting the production efficiency of cutting operations, increasing manufacturing costs, and large chip deformation, and enhancing the ability to prevent deviation. , Increase the number of repeated use, the effect of smooth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention will be described in detail below with examples, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

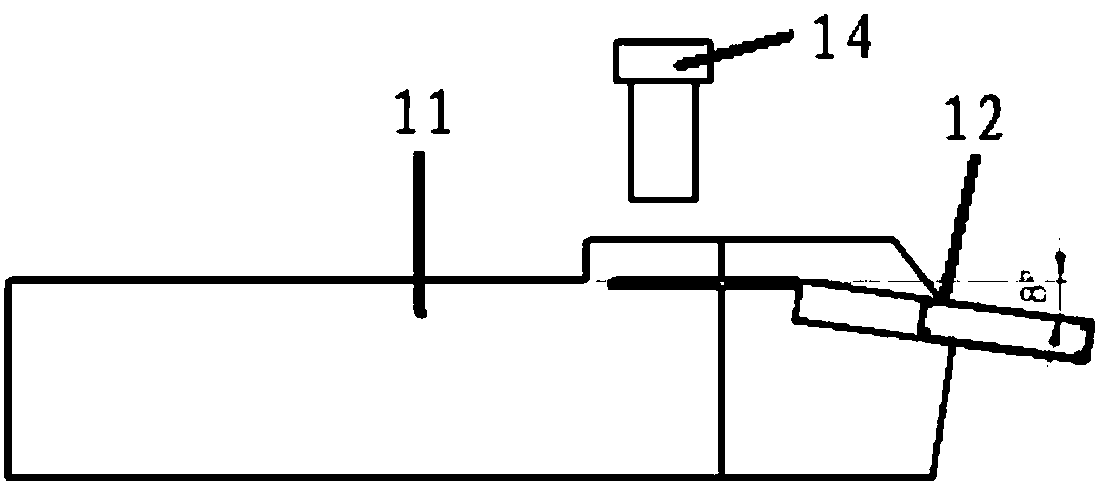

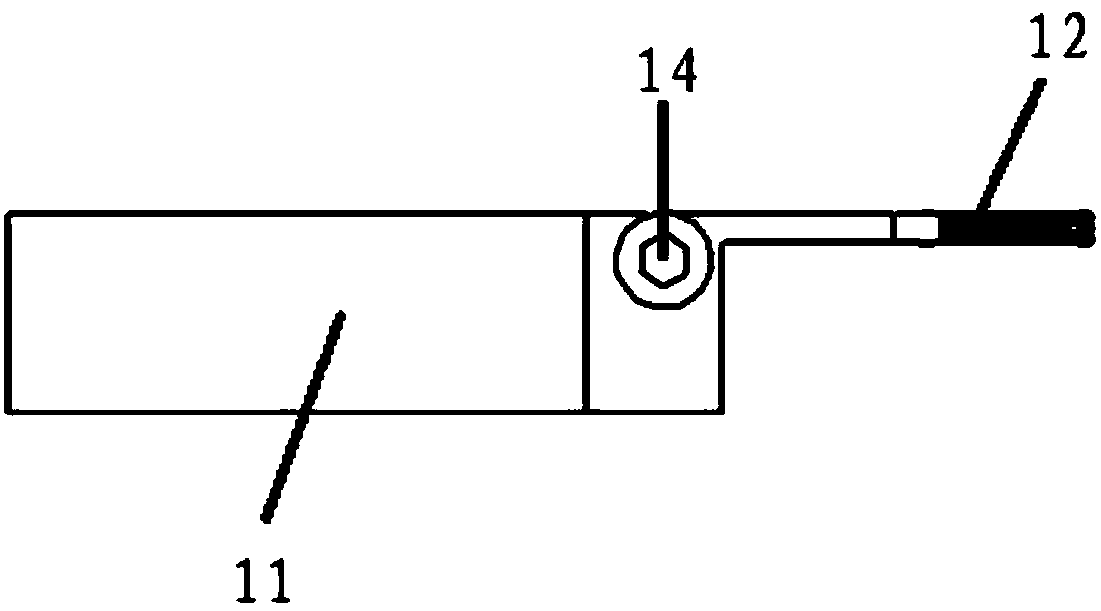

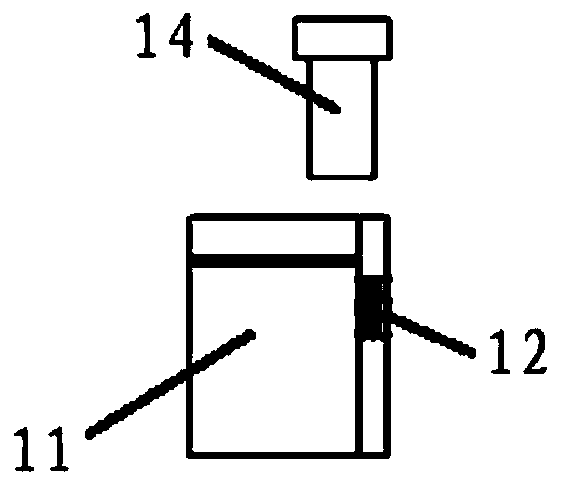

[0043] The invention discloses a machine clip cutting knife, such as Figure 1-Figure 3 As shown, comprise cutter body 11, the head of described cutter body 11 is connected with blade 12 by fixing bolt 14, and cutter back angle is 5~8 °, and blade 12 is straight type cutter outer contour shape and is cuboid; Blade 12 Both ends of the blade are provided with two cutting heads; the two cutting heads at the same end are axisymmetric, and are respectively arranged on the top and bottom of the blade 12;

[0044] Such as Figure 4 As shown, taking the cutting head arranged on the top of the front end of the blade 12 as an example: the cutting head includes a cutting edge 1, a chip pocket 3, a rake face 4, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com