Method for efficiently and controllably processing large-area silicon micro-nano structure

A large-area, silicon micro-nano technology, applied in the field of femtosecond laser applications, can solve the problems of low processing efficiency and high cost, and achieve the effects of improving processing efficiency, facilitating operation and control, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

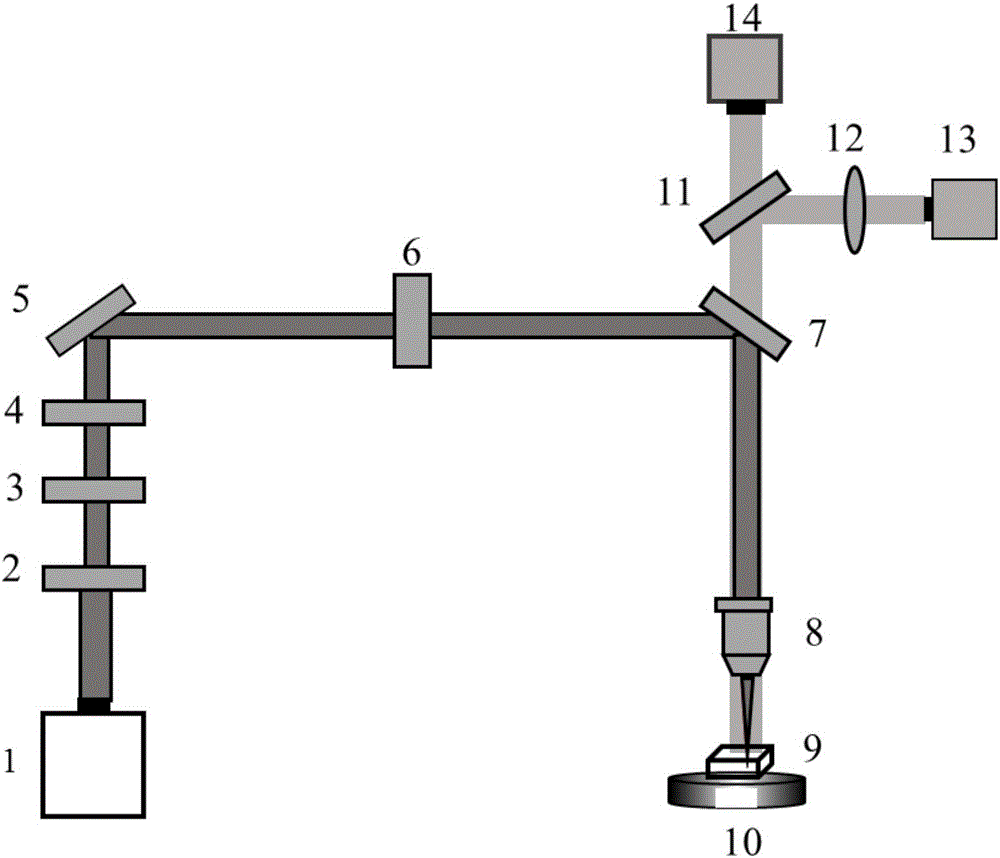

[0030] The femtosecond laser system in this embodiment adopts the laser produced by American Spectra Physics Company, the laser center wavelength is 800nm, the pulse width is 35fs, the repetition frequency is adjustable at 1KHz, the single pulse maximum energy is 3mJ, and the light intensity distribution is Gaussian , linearly polarized.

[0031] The processing material 9 is N-type non-doped single crystal silicon with crystal orientation 100, and its size is 10mm×10mm×1mm. Of course, those skilled in the art know that the actual processed object is not limited to single crystal silicon, it can be any other substance whose chemical properties can be changed by laser irradiation.

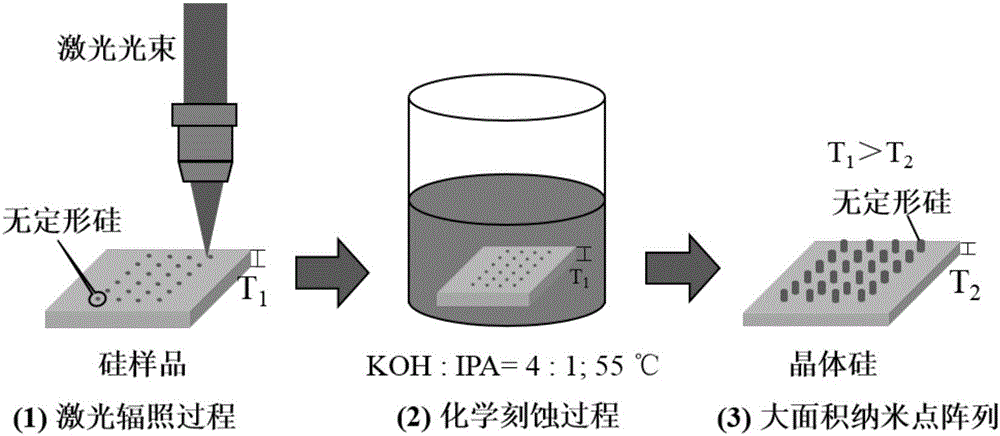

[0032] A method for efficiently processing large-area silicon micro-nano structures combined with chemical etching-assisted femtosecond laser proposed by the present invention, the processing optical path diagram and the schematic diagram of the experimental steps are as follows figure 1 and figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap