Liquid level control system of five-axis machining center spindle box

A five-axis machining center and liquid level control technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of spindle flooding, liquid level instability, etc., and achieve the effect of improving the efficiency of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The liquid level control system of the spindle box of the five-axis machining center of the present invention is described in conjunction with the accompanying drawings and specific examples.

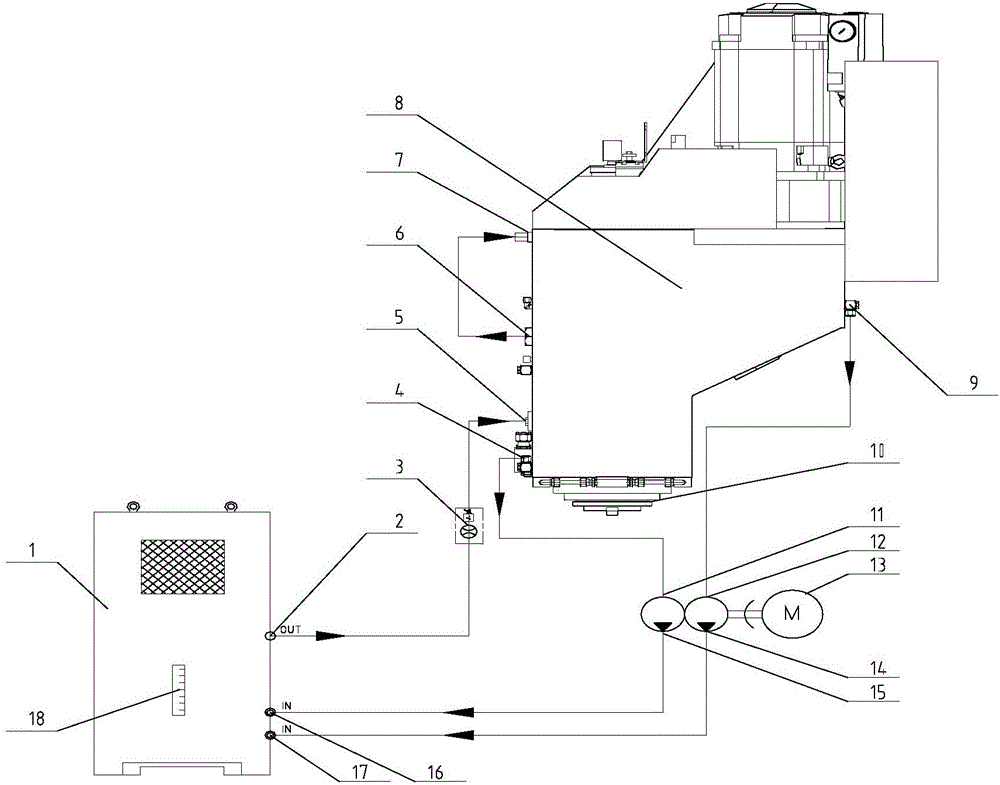

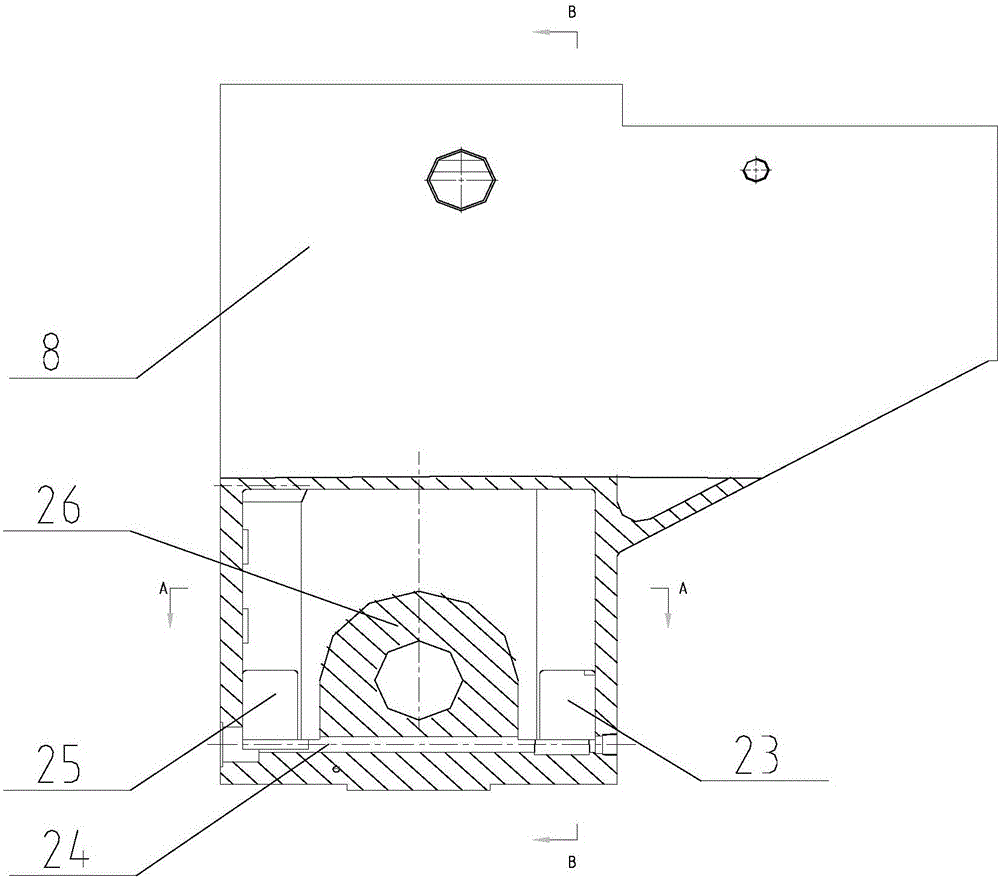

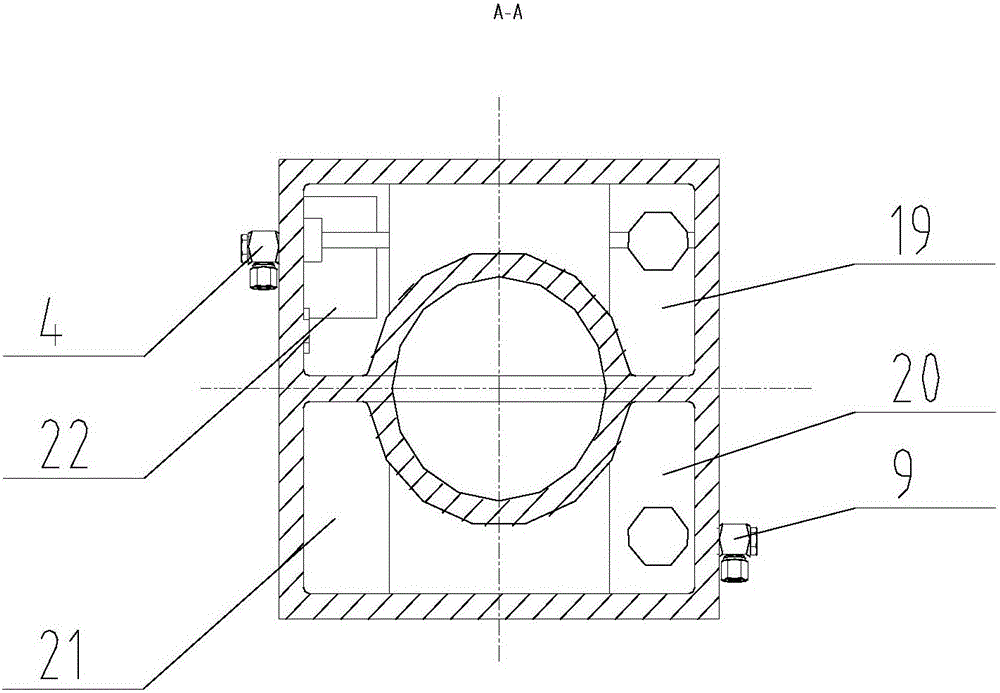

[0017] The liquid level control system of the present invention adopts an oil cooler with liquid level alarm and flow monitoring as an oil liquid delivery device, and also includes a spindle box, an oil liquid recovery device and a liquid level electrical control program unit, and is characterized in that the oil cooler Add a liquid level switch 18 and a flow switch 3 to 1. The liquid level switch 18 is installed on the tank wall of the oil cooler 1. According to the flow switch 3 on the oil outlet pipe of the oil cooler, it feeds back to the liquid level electrical control program unit to control the volume of the oil tank. start-stop command. The control amount of the oil tank volume is obtained by adding the maximum dynamic oil volume of the inner chamber of the headstock 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com