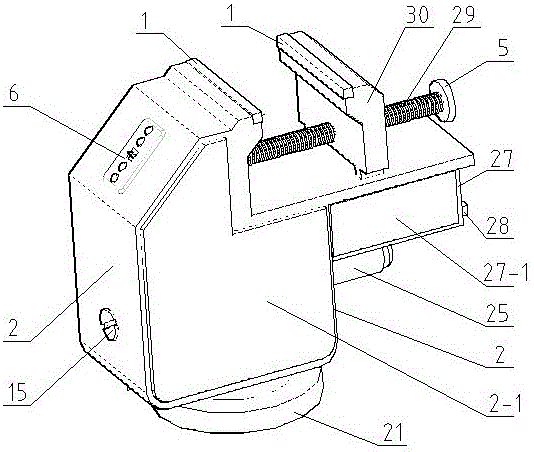

Electric bench screw

A bench vise, electric technology, applied in the field of bench vise, can solve the problems of low work efficiency, slow speed, high labor intensity, and achieve the effect of less original parts, high efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

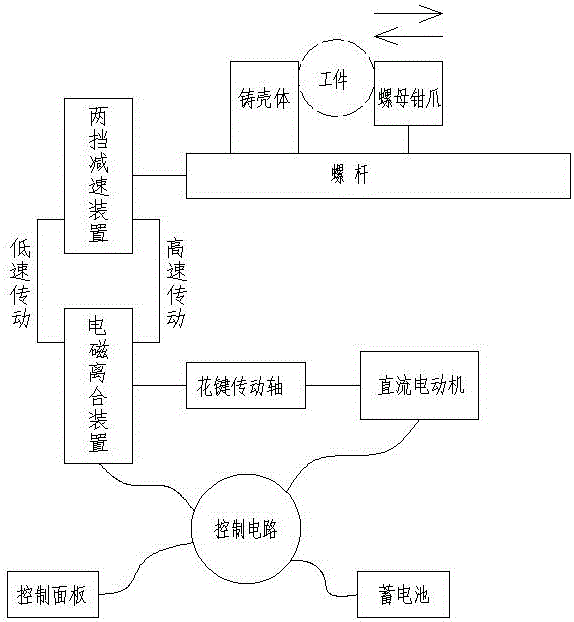

[0019] According to the present invention figure 1 , figure 2 Shown; The present invention is to drive the spline drive shaft → transmission → electromagnetic clutch device → transmission → two-speed deceleration device → transmission → screw to rotate to make the nut claw move by accumulator to DC motor power supply; control circuit and accumulator, DC motor, electromagnetic The clutch device and the control panel are connected by wires; the operation control panel can realize the left and right movement of the nut claws, and can perform the clamping or loosening function on the workpiece.

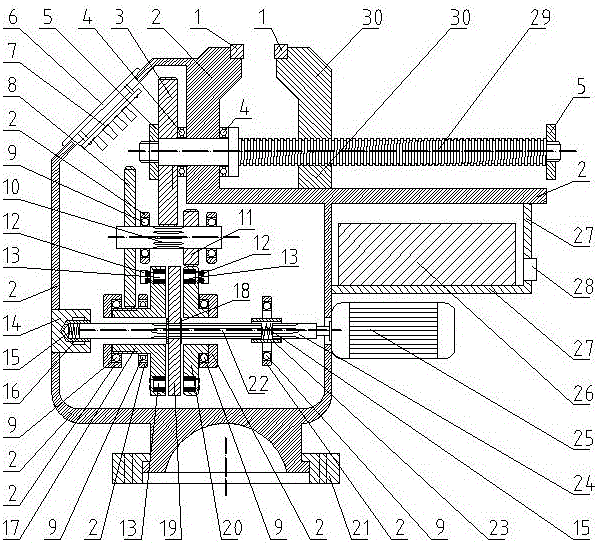

[0020] The structural sectional view of embodiment 1 of the present invention: in image 3 Middle; the DC motor (25) is fixedly installed on the cast housing (2), connected with the short spline shaft (24), and the short spline shaft (24) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com