High speed railway ballastless track pre-tensioning method flow unit production line

A ballastless track, high-speed railway technology, applied in conveyors, ceramic molding machines, mechanical conveyors, etc., can solve the problems of synchronous control error of tension cylinder displacement, individual steel bar tension error, safety hazards, etc., and reduce production. cost, product quality assurance, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

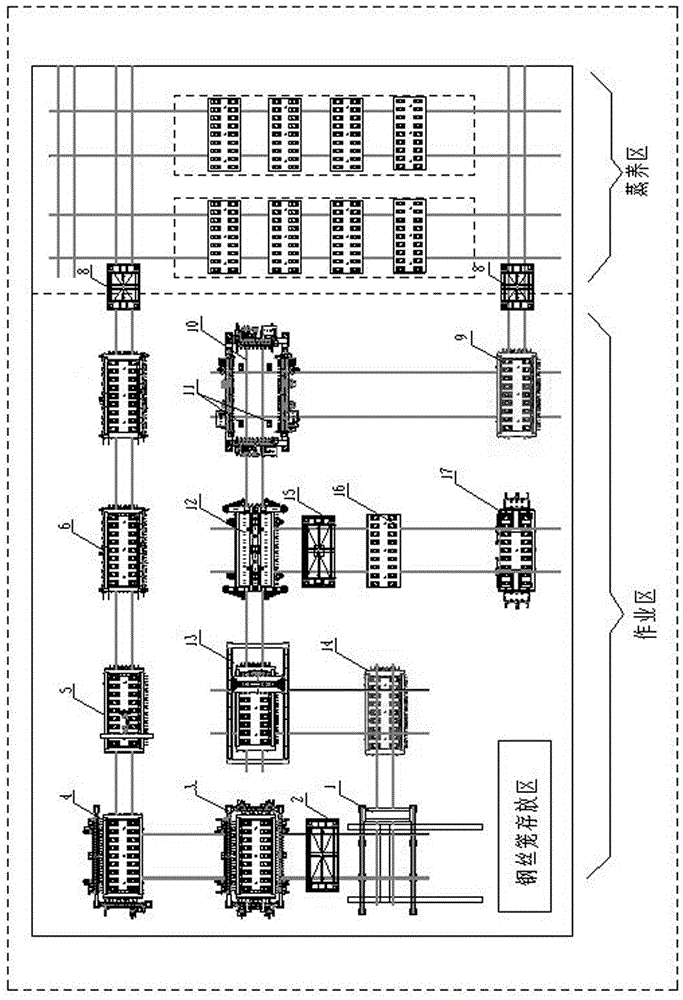

[0027] Refer to attached figure 1 , the high-speed railway ballastless track slab pretensioning assembly line production line of the present invention mainly includes two areas: an operation area and a steam curing area. Each job station is set in sequence according to the process sequence. Each station is fixed on the ground by ground fixing brackets through anchor bolts, and there is a running space between the work station and the ground for the mobile trolley to move. If the length of the work site is sufficient, each station can be arranged in a straight line along a center line according to the process sequence. A movable running trolley 2 is provided, and the running trolley drives the track plate mold and / or the track plate to the corresponding station or moves the track plate mold and / or the track plate to the next station according to the process requirements. Positioning support 11 matching the working height of the station is provided on the inner side of each st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com