Servo-motor-driven lifting device for one-step injection-blowing hollow molding machine

A technology of servo motor and lifting device, applied in the field of plastic machinery, can solve the problems of large impact, slow response and high noise when the action is in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

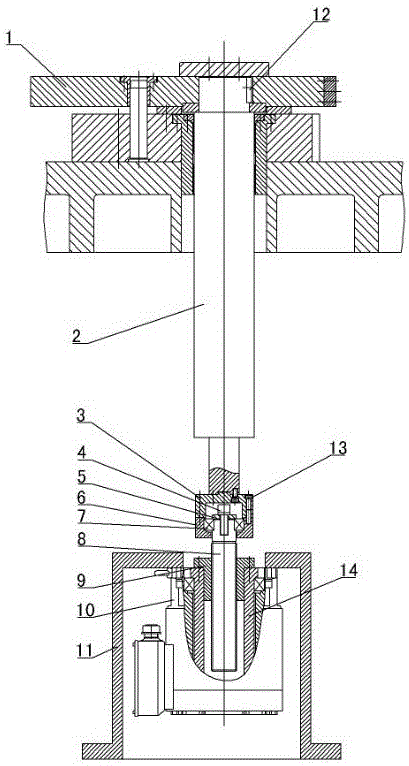

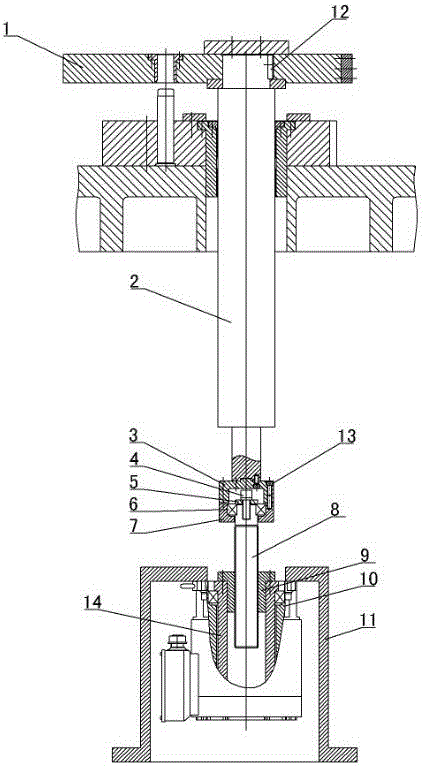

[0009] The invention relates to a servo motor-driven lifting device for a one-step injection blow molding machine, such as figure 1 , figure 2 As shown, it includes a mounting seat 11, on which the main shaft 2 is arranged, and the turntable 1 is installed on the main shaft, and the servo motor 10 is arranged in the mounting seat 11, and the output shaft 14 of the servo motor 10 is connected to the guide sleeve 9, and the guide sleeve 9 A ball screw 8 is provided, and the ball screw 8 is connected to the main shaft 2 through a connecting mechanism. When the turntable is raised, the control system sends an instruction, and the servomotor 10 executes the action. The output shaft 14 of the servomotor is a hollow shaft rod, which is a prior art, and the guide sleeve 9 is arranged in the hollow shaft rod, so , when the output shaft 14 rotates, it drives the guide sleeve 9 to rotate, and the guide sleeve 9 is then driven by the ball screw 8 to change the rotation into a linear mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com