A kind of lightweight multi-layer composite sound insulation and heat insulation material and preparation method thereof

A technology of multi-layer composite and thermal insulation materials, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., which can solve the problem of difficult balance between sound insulation and density of sound insulation materials, uncontrollable layer interface and complex preparation process and other problems, to achieve the effect of easy structure control, good sound insulation and heat insulation effect, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

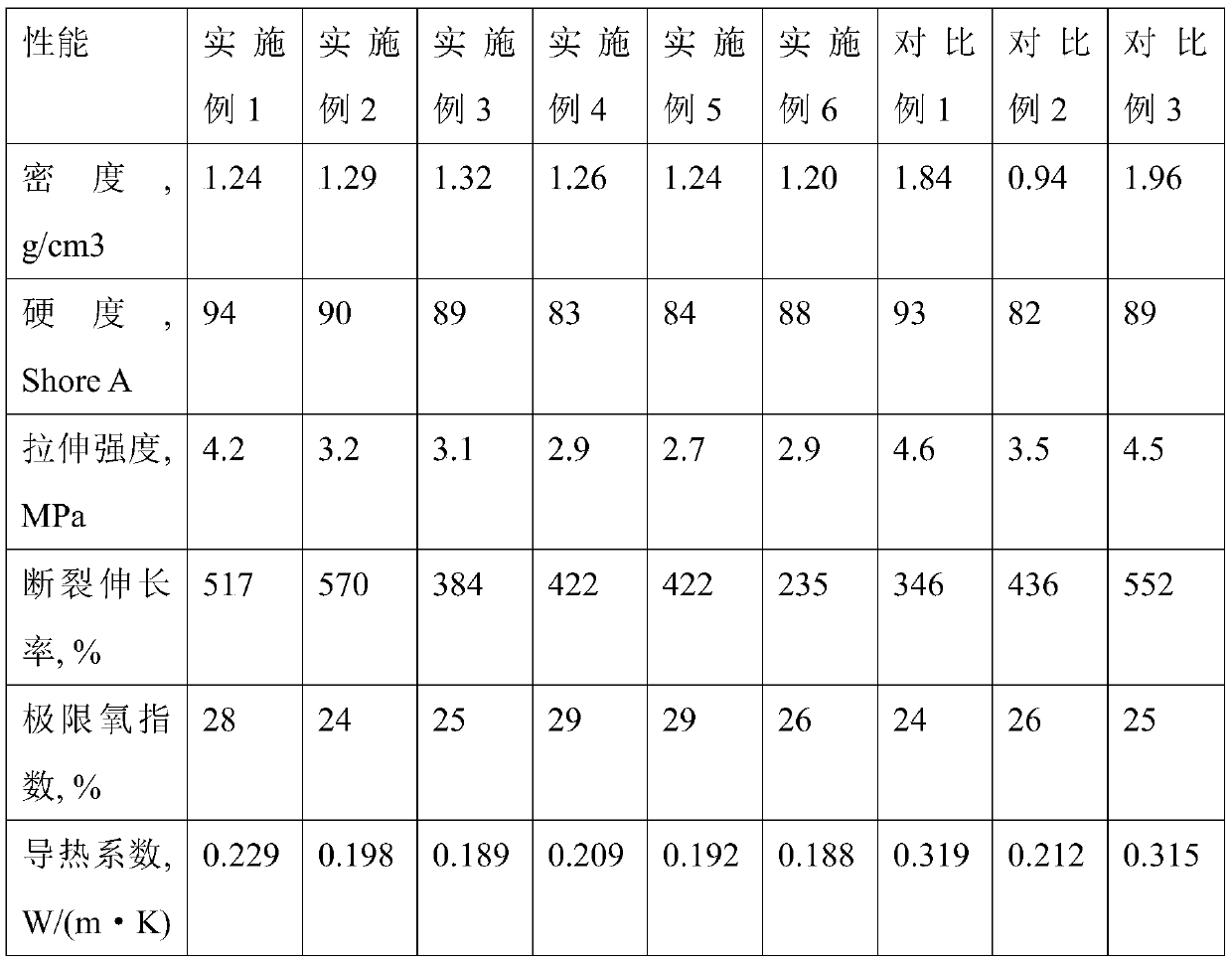

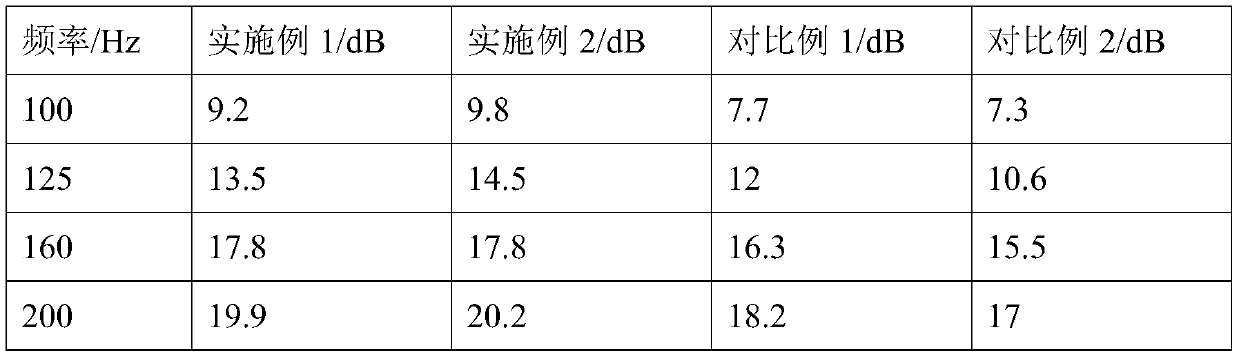

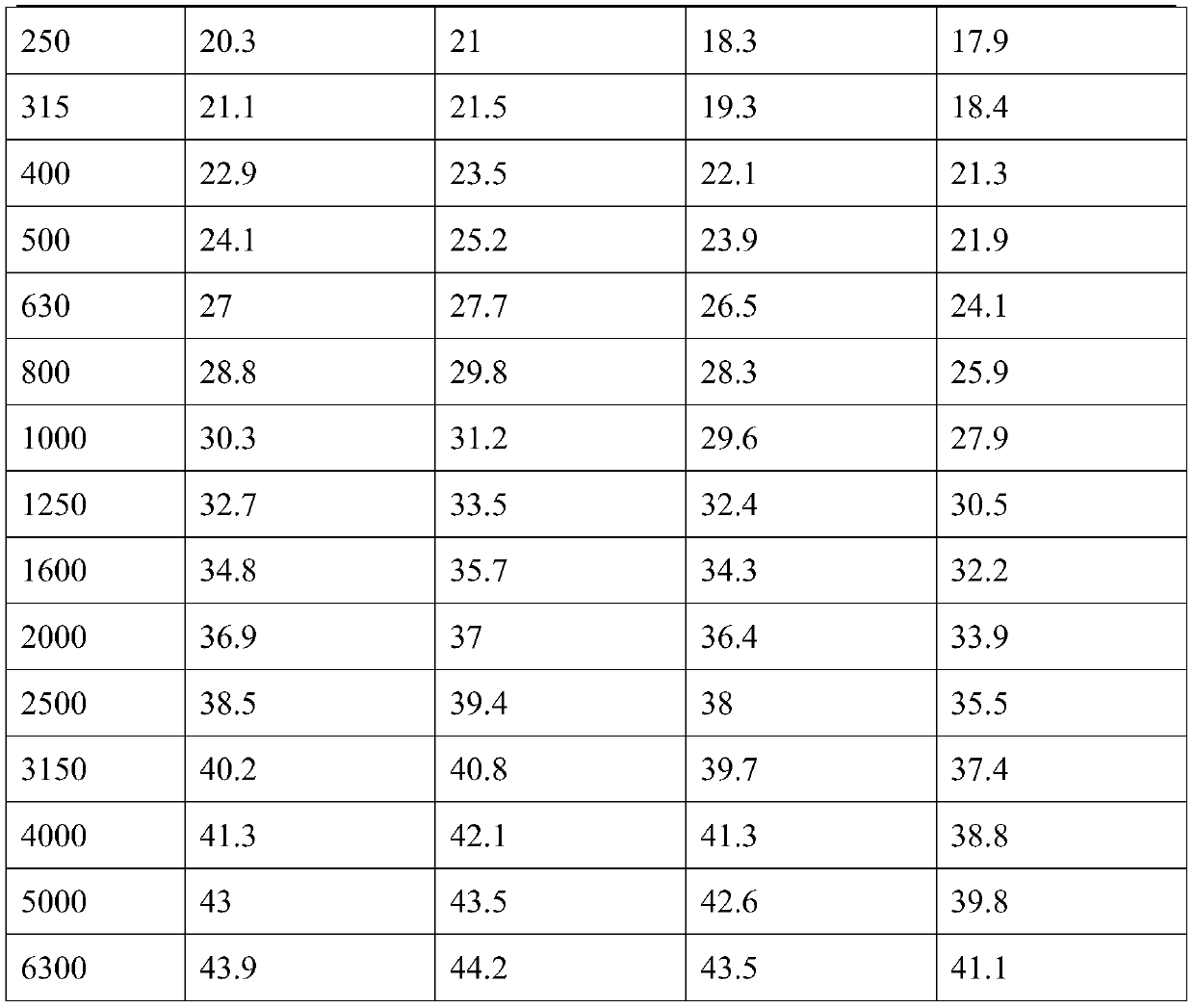

Examples

Embodiment 1

[0042] The ratio of each component of the polymer material A is: low-density polyethylene: 60 parts, ethylene-vinyl acetate copolymer: 20 parts, polyolefin elastomer POE: 20 parts, hollow glass microspheres (average particle size 80 μm, Density 0.6g / cm 3 , compressive strength 82MPa): 50 parts, heavy calcium carbonate: 80 parts by weight, aluminum hydroxide: 100 parts, plasticizer is white oil: 3 parts, lubricant is stearic acid: 2 parts, colorant is carbon Black: 2 parts, coupling agent is titanate: 2 parts.

[0043] The ratio of each component of the polymer material B is: low-density polyethylene: 60 parts, ethylene-vinyl acetate copolymer: 20 parts, polyolefin elastomer POE: 20 parts, calcium carbonate: 280 parts, aluminum hydroxide: 200 parts, the plasticizer is white oil: 5 parts, the lubricant is stearic acid: 2 parts, the colorant is carbon black: 2 parts.

[0044] The density of polymer material A is 1.04g / cm 3 , with a modulus of 5.34×10 3 MPa; the density of pol...

Embodiment 2

[0047] The ratio of each component of the polymer material A is: ethylene-vinyl acetate copolymer: 50 parts, low-density polyethylene: 30 parts, polyolefin elastomer POE: 20 parts, hollow glass microspheres (average particle size 50 μm, Density 0.3g / cm 3 , compressive strength 82MPa): 80 parts, heavy calcium carbonate: 80 parts, plasticizer is naphthenic oil: 3 parts, lubricant is stearic acid: 1.5 parts, colorant is carbon black: 2 parts, coupling The agent is titanate: 2 parts.

[0048] The ratio of each component of the polymer material B is: ethylene-vinyl acetate copolymer: 50 parts, low-density polyethylene: 30 parts, polyolefin elastomer POE: 20 parts, barium sulfate: 500 parts, and the plasticizer is Naphthenic oil: 3 parts, lubricant: stearic acid: 1.5 parts, colorant: carbon black: 2 parts.

[0049] The density of polymer material A is 0.97g / cm 3 , with a modulus of 3.68×10 3 MPa; the density of polymer material B is 1.85, and the modulus is 4.67×10 3 MPa.

[0...

Embodiment 3

[0052] The ratio of each component of polymer material A is: styrene-butadiene-styrene block copolymer: 75 parts, polyolefin elastomer POE: 25 parts, hollow glass microspheres (average particle size 50 μm, density 0.9g / cm 3 , compressive strength 70MPa): 100 parts, talcum powder: 100 parts, plasticizer is naphthenic oil: 4 parts, lubricant is 1.5 parts of stearic acid, colorant is carbon black 2 parts, coupling agent is titanic acid Esters: 2 parts.

[0053] The ratio of each component of polymer material B is: styrene-butadiene-styrene block copolymer: 75 parts, polyolefin elastomer POE: 25 parts, barium sulfate: 400 parts, plasticizer is ring Paraffin oil: 3 parts, lubricant is 1.5 parts of stearic acid, coloring agent is 2 parts of carbon black.

[0054] The density of polymer material A is 0.88g / cm 3 , with a modulus of 3.42×10 3 MPa; the density of polymer material B is 1.82, and the modulus is 4.82×10 3 MPa.

[0055] Mix the polymer material A and the polymer mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com