A high-barrier high-temperature-resistant packaging film that does not roll after sterilization

A high-temperature, high-barrier technology, applied in the field of high-barrier, non-rolling packaging films after high-temperature sterilization, can solve problems such as curling, packaging films prone to curling, and easy curling, etc., to achieve strong barrier properties and achieve cost-effective Control and maintain the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation of the present invention will be further described below in conjunction with the examples.

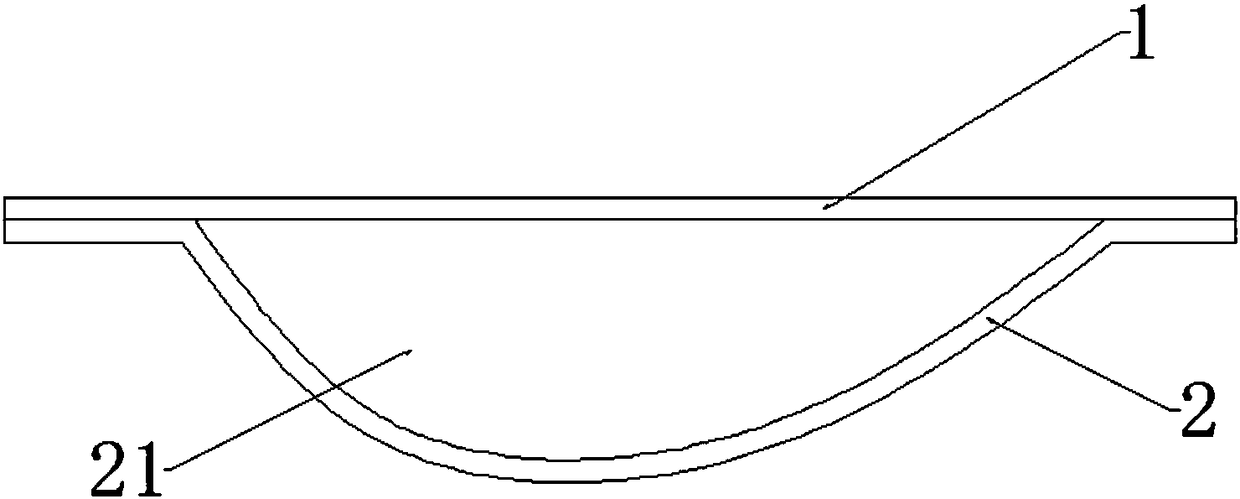

[0010] Such as figure 1 As shown, a high-barrier high-temperature-resistant packaging film that does not roll after sterilization includes an upper film 1 and a lower film 2. The upper film is a flat film, and the lower film has a storage cavity 21. The upper film and the lower film are heat-sealed. The surface of the upper film is physically cross-linked to make its melting point reach 180-190°C, which can ensure that the packaging film maintains good flatness and no curling during the high-temperature sterilization process. The upper film includes the CPP layer and the CPP layer. The first adhesive layer, the first PA layer, the ink layer, the second adhesive layer, and the PE layer are sequentially arranged on the lower surface, and the CPP layer includes a CPP copolymer layer on the uppermost layer, an intermediate layer blended with PP and POP, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com