Segmentation and phase-split insulator

An insulator and phase separation technology, applied in the direction of overhead lines, etc., can solve the problems of replacement of consumable parts, damage to the integrity of the contact surface, and accidents, so as to facilitate installation and disassembly operations, easy on-site replacement and maintenance, and ensure smooth transition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

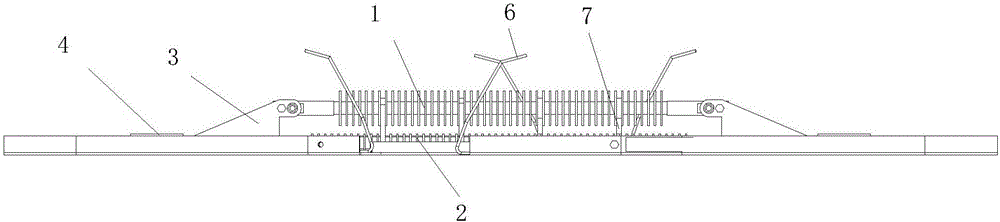

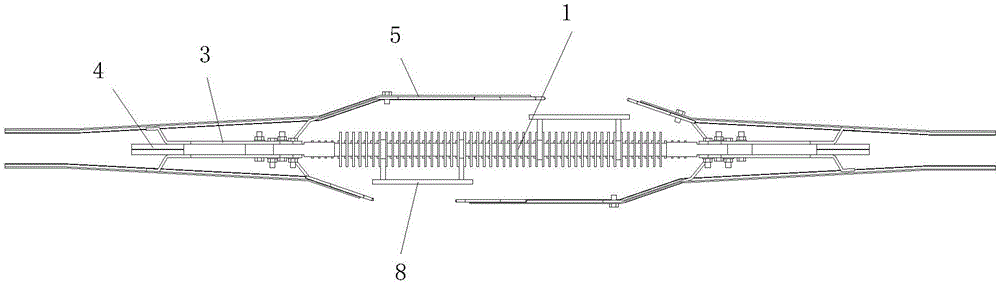

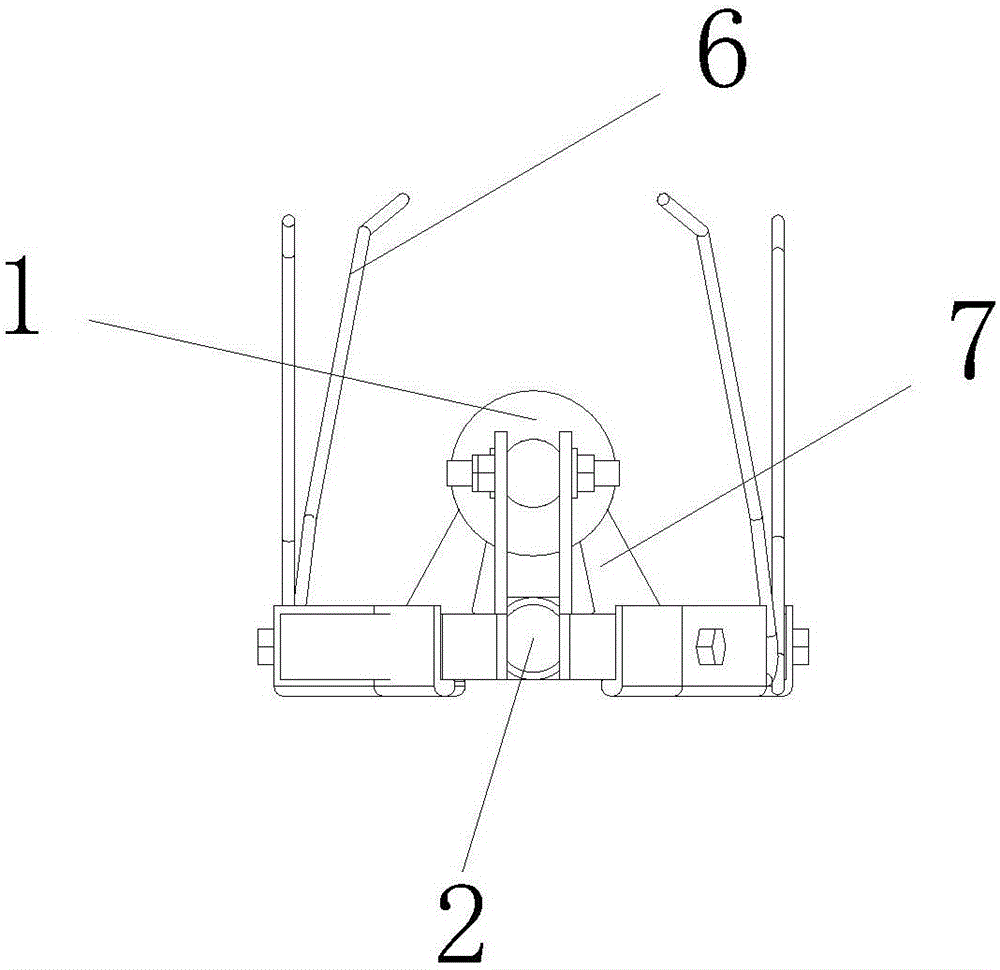

[0025] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a main insulating structure, a slide plate arranged on the main insulating structure and fixing splints 3 arranged at both ends of the main insulating structure, and the main insulating structure includes an upper insulating rod 1 arranged horizontally and an The lower insulating rod 2 below the insulating rod 1 and arranged vertically parallel to the upper insulating rod 1, the fixed splint 3 is connected to both ends of the upper insulating rod 1 and the lower insulating rod 2, and the sliding plate includes a main sliding plate 5 and a Auxiliary sliding plates 8 arranged on both sides of the insulating rod 2 and in parallel with the lower insulating rod 2, contact wire joint clamps 4 are arranged on the outer sides of the two ends of the lower insulating rod 2, the main sliding plate 5 and the contact wire joint clamps 4 Both are fixedly connected with the fixed splint 3, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com