Vehicular interceptor and high-pressure blow-molding rapid forming process thereof

A molding process and spoiler technology, which is applied in the direction of body, application, household components, etc., can solve the problems of easy damage or deformation, reduced rear wheel grip, and more steering of the car, so as to increase the compression resistance and bending resistance. capacity, improve installation efficiency, and prevent rainwater from gathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

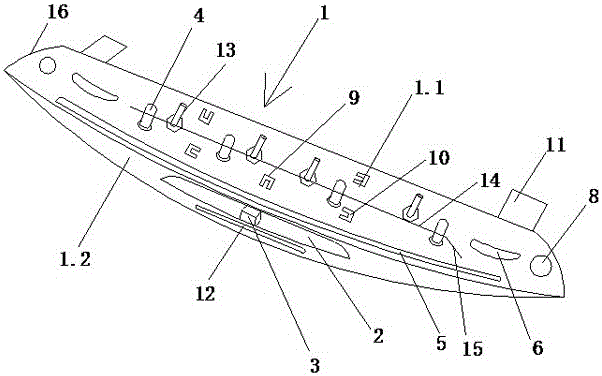

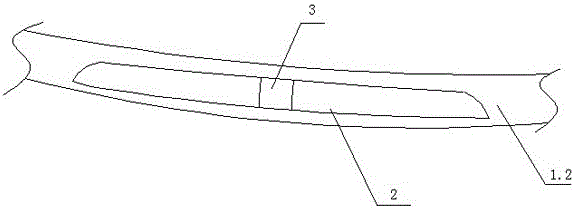

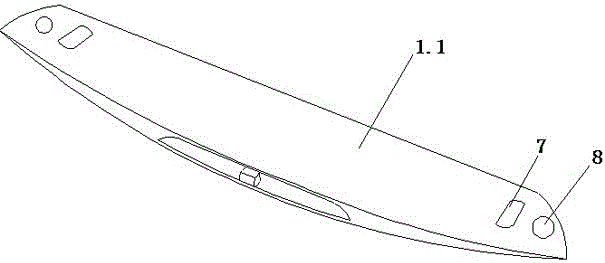

[0024] Such as Figure 1 to Figure 6 , the present invention relates to a spoiler for vehicles, comprising a spoiler body 1, a through hole 2 and a process piece 3, which improves the heat resistance of the spoiler, and the spoiler body 1 is composed of a bottom plate 1.1 and a vertical plate 1.2, the vertical plate 1.2 is provided with a through hole 2, and the through hole 2 is elongated. The process piece 3 is arranged in the through hole 2, and its two ends are connected and fixed with the vertical plate 1.2. The spoiler body 1 Bolts 4 are provided on the back of the spoiler, and the bolts 4 include a bolt seat 4.1, a bolt head 4.2 and a bolt protective sleeve 4.3. The bolt seat 4.1 is fixed on the back of the spoiler body 1, and the bolt head 4.2 is fixed on the bolt seat 4.1. On, the upper end of the bolt protective sleeve 4.3 is sealed, and the lower end is set on the bolt head 4.2;

[0025] The back of the spoiler body 1 is provided with a long inner concave rib 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com