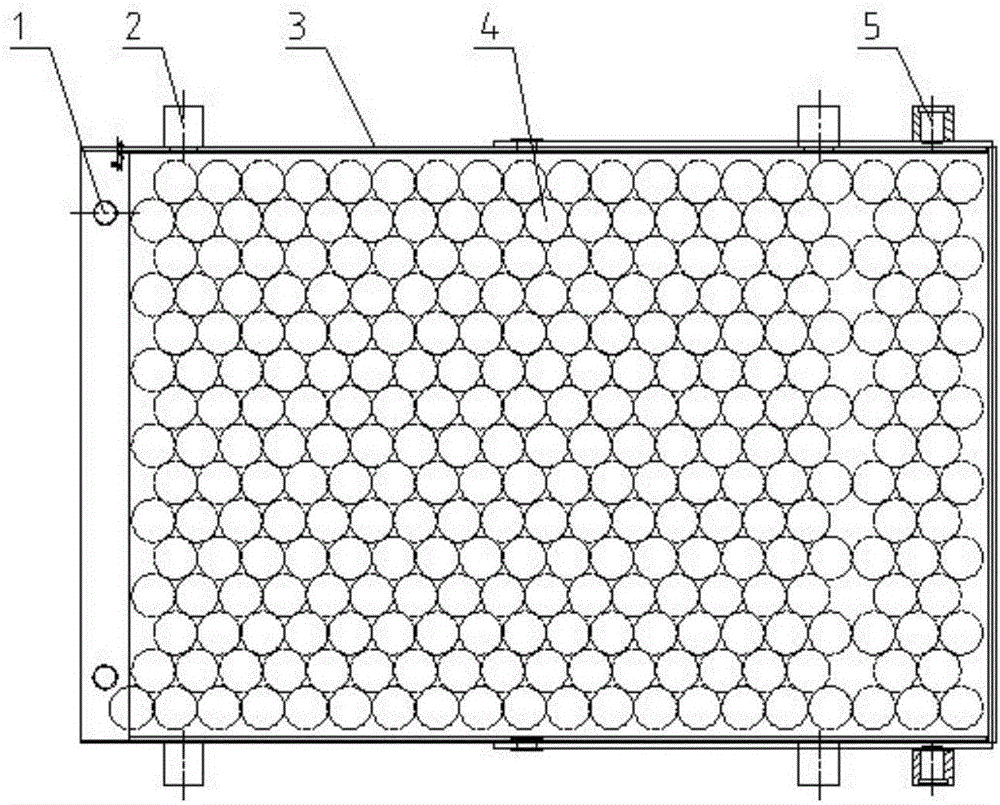

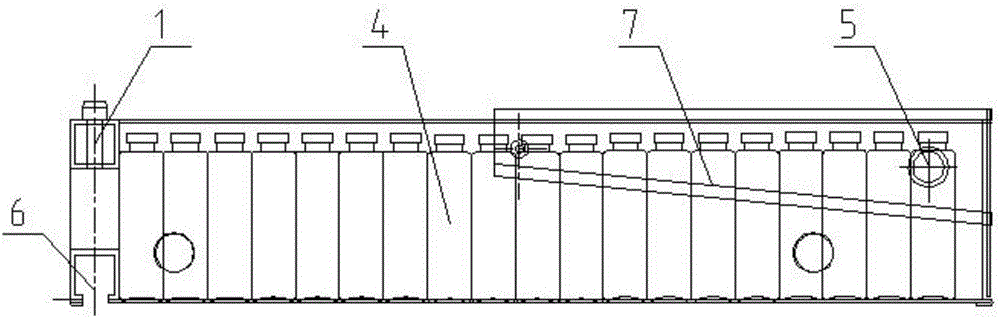

Small-capacity oral liquid bottle storage tray

An oral liquid, small-capacity technology, applied in the field of Ejiao pulp product production equipment, can solve problems such as low efficiency of manual handling of bottle storage trays, and achieve the effects of ensuring preservation integrity, improving clamping stability and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] On the basis of Embodiment 1, different from Embodiment 1, the limiting through-hole is set as a bar-shaped hole with semicircular arcs at both ends, and the wall of the limiting through-hole is covered with an anti-skid pad along the periphery. It plays an anti-slip effect, and avoids the oral liquid bottle 4 from toppling over.

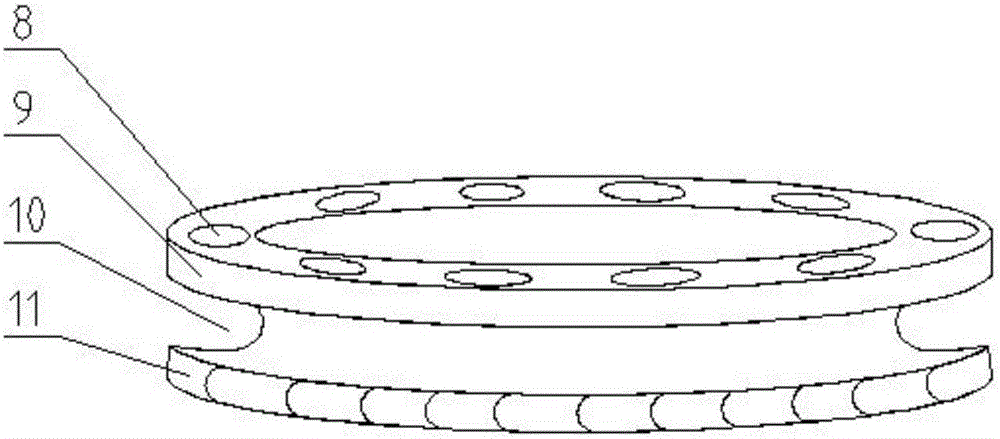

[0027] Such as image 3 As shown, the anti-slip pad is an integral structure formed by connecting the upper hollow cavity 9 and the lower cavity 11 in a hollow shape. The peripheries of the upper cavity 9 and the lower cavity 11 are inwardly recessed to form a U-shaped groove 10 . The elastic structure of the upper and lower pockets 11 enables the anti-slip pad to play a certain role in buffering and shockproofing. The U-shaped groove 10 is convenient to engage on the hole wall of the limiting through hole, and the upper and lower edges are covered evenly.

[0028] The upper cavity 9 protrudes from the wall of the cavity and is provided with...

Embodiment 3

[0030] On the basis of Embodiment 1, different from Embodiment 1, the transfer button 2 and the opening button 5 are cylindrical parts formed by turning, and the outer side of the opening button 5 is equipped with a sleeve, and the opening button 5 and the transfer button 2 The outer cover is provided with a protective cover.

[0031] Such as Figure 4 As shown, the side wall of the protective cover adopts a hollow cylinder structure formed by erecting inner cylinder 14 and outer cylinder 12. Both inner cylinder 14 and outer cylinder 12 are made of elastic rubber pad material, and inner cylinder 14 1. Between the outer cylinders 12, half-moon arc-shaped steel bars 13 criss-crossing are arranged.

[0032] The inner and outer cylinders 12 of the protective cover have a certain degree of elasticity, and the internal arc-shaped steel bars further strengthen the support stability. When the manipulator is engaged on the outer protective cover of the transport button 2, the clamping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hem width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com