Composite plate turnover

A composite plate and turning machine technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, high manufacturing cost, and bulky turning machine equipment, and achieve energy saving and low cost , The effect of low machine height requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example example

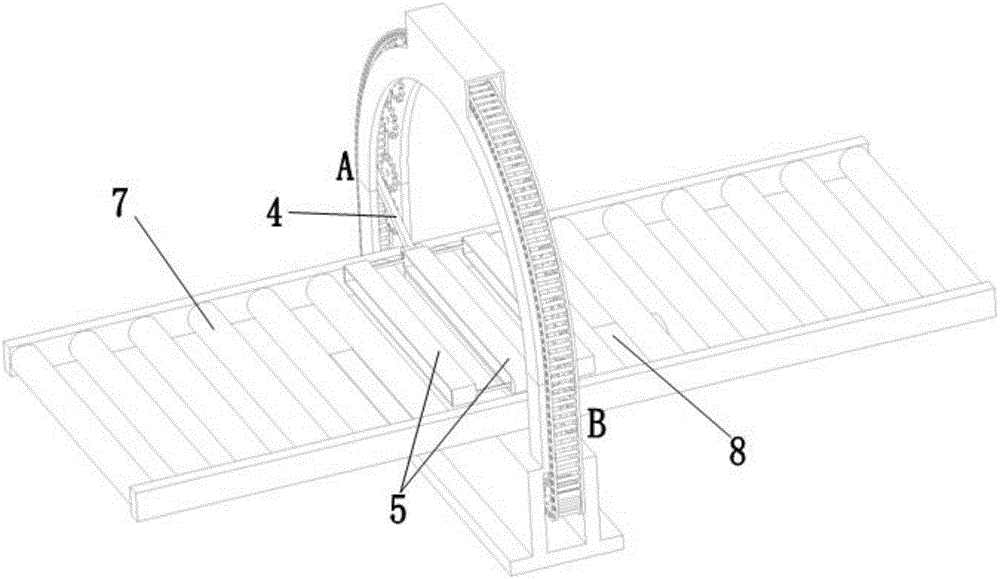

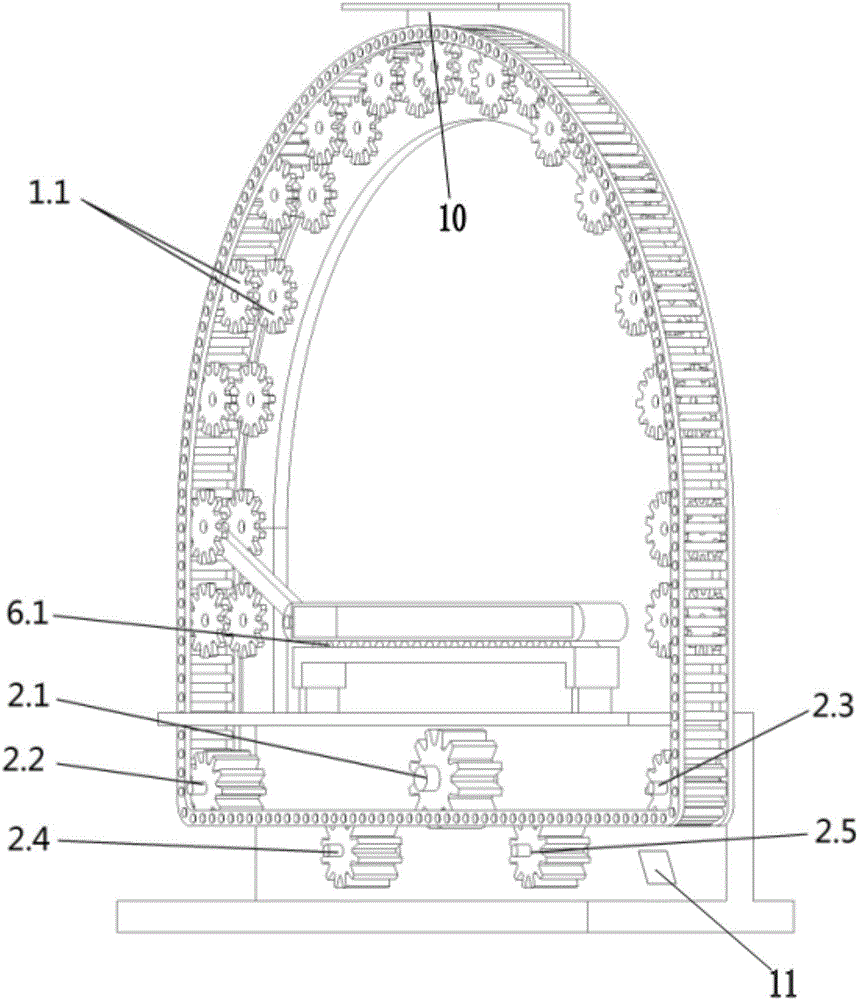

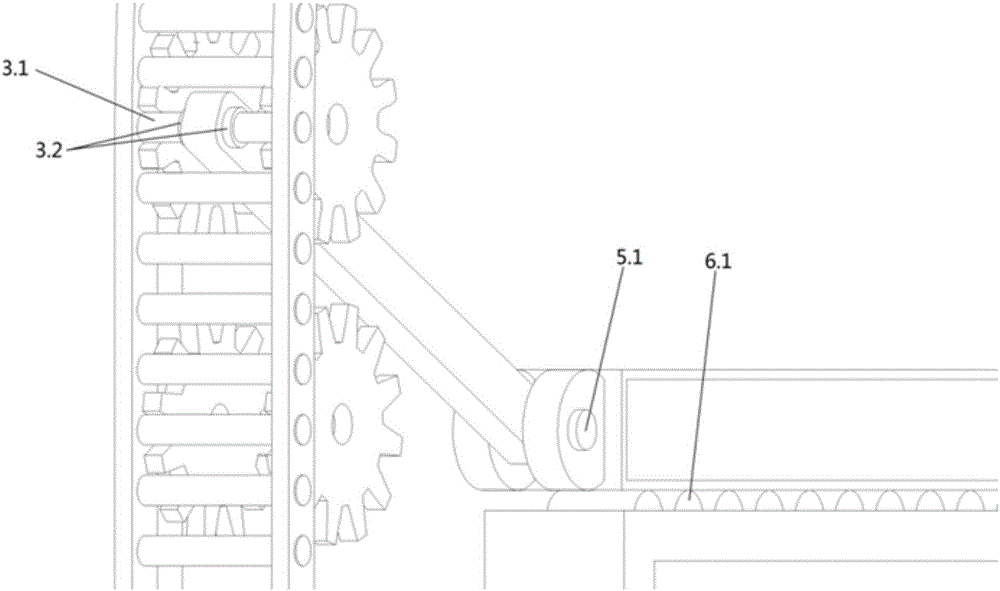

[0071] Working principle of the present invention is (narrate with the first embodiment as example):

[0072] The plate to be flipped is conveyed into the plate clamping frame 5 by the supporting roller 7, and the power sprocket 2.1 rotates under the drive of the motor 8, driving the power sprocket 2.1 set on the upper frame sprocket 1.1 and the lower frame, and the lower frame sprocket 1 2.2, The lower frame sprocket 2 2.3, the chain 3 sandwiched between the lower frame sprocket 3 2.4, the lower frame sprocket 4 2.5 and the power sprocket 2.1 moves along the upper frame 1 from A to B, and then drives the connecting rod 4 And the plate clamping frame 5 moves from A to B direction along the inverted U-shaped trajectory of the upper frame 1, and the plate clamping frame 5 slides on the pulley platform 6. When the connecting rod 4 is driven by the chain 3 from the direction A to the top of the upper frame 1, The plate clamping frame 5 is perpendicular to the ground, and the arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com