Intelligent brick clamping machine

A brick clamping machine, intelligent technology, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of increased cost of mechanical structure, unfavorable operation simplification, broken, etc., to achieve simple structure, daily Low-maintenance, easy-to-promote effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but not limited to the following content.

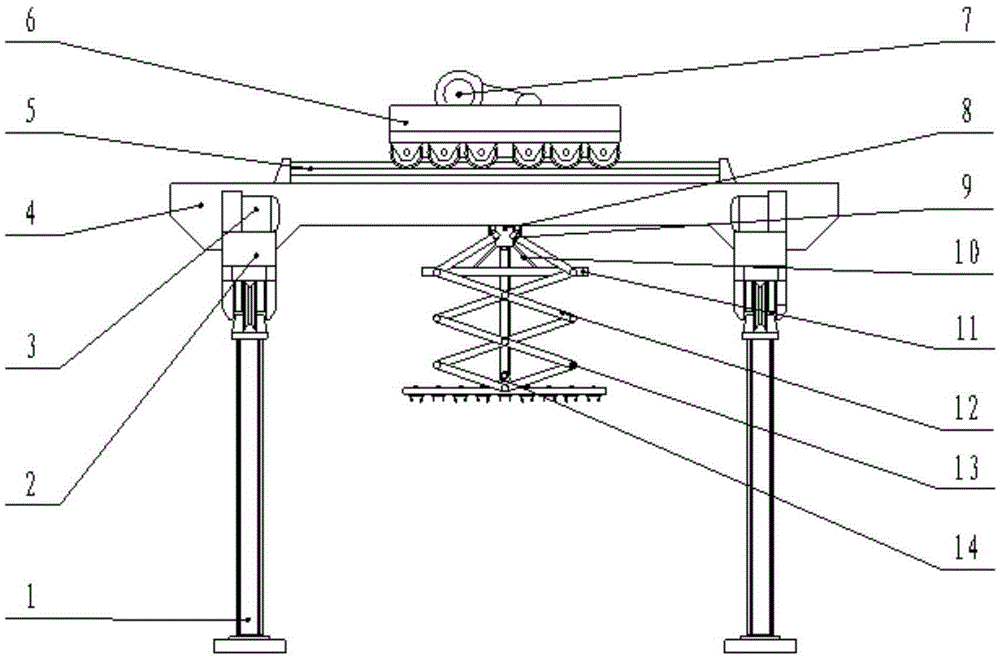

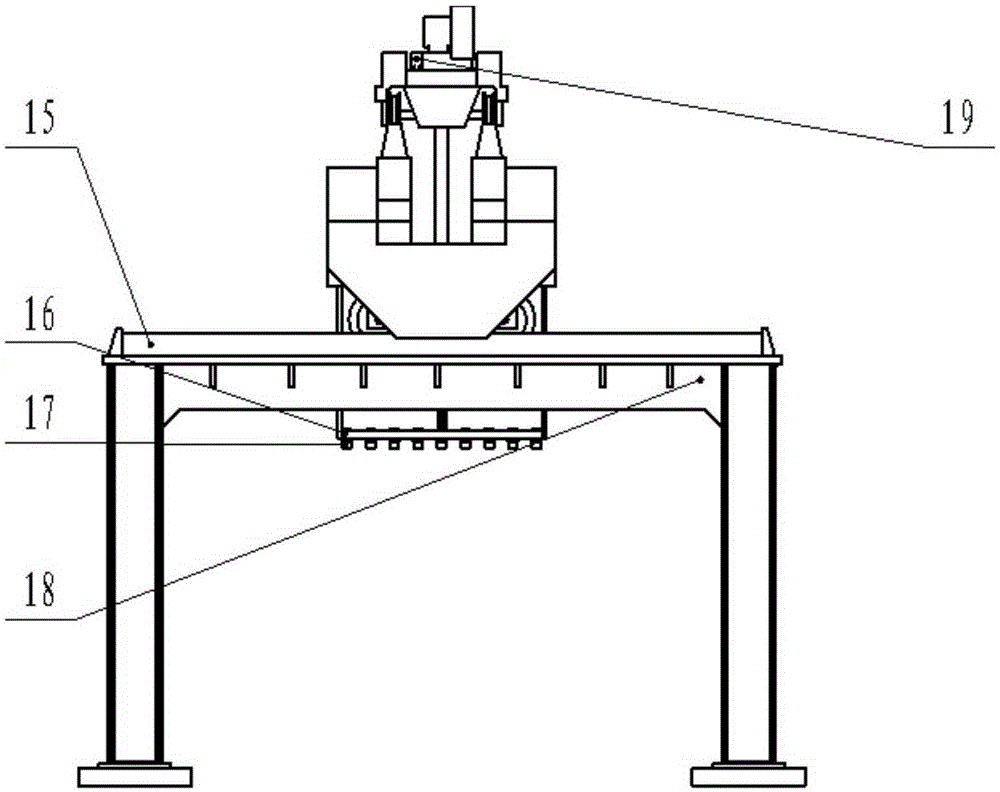

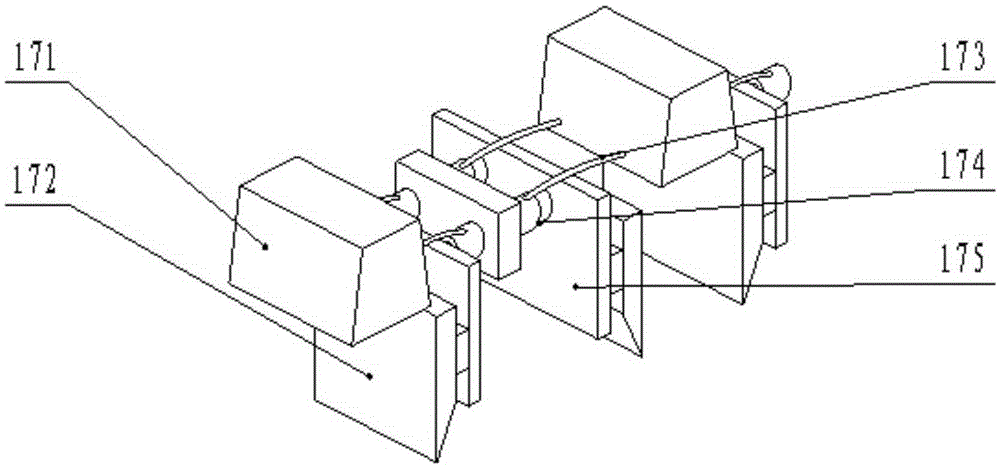

[0016] Intelligent brick clamping machine of the present invention such as figure 1 with figure 2 Shown, mainly be made up of driving mechanism, elevating mechanism and clamping brick mechanism 17. Wherein the main structure of the traveling mechanism is as follows, the pillar 1 is fixed on the ground in the brick kiln, the traveling main beam 18 is erected on the top of the pillar 1, each traveling main beam 18 is laid with a main beam rail 15, two main beam rails 15 It is assumed that there is a driving sub-beam 4, and two sets of main beam wheel trains 2 are installed under the driving sub-beam 4, which are used for the front and rear movement of the driving sub-beam 4 above the driving main beam 18, and the power source is 2 groups installed on the driving The main beam driving motor 3 of the subbeam 4 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com