A multi-functional fuel filling pipeline system and its application method

A pipeline system, fuel filling technology, applied in packaging, liquid distribution, conveying or transfer devices, transportation and packaging, etc., can solve the problems of mixing function, difficult to meet the requirements of use, and can not be withdrawn from the pipeline, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

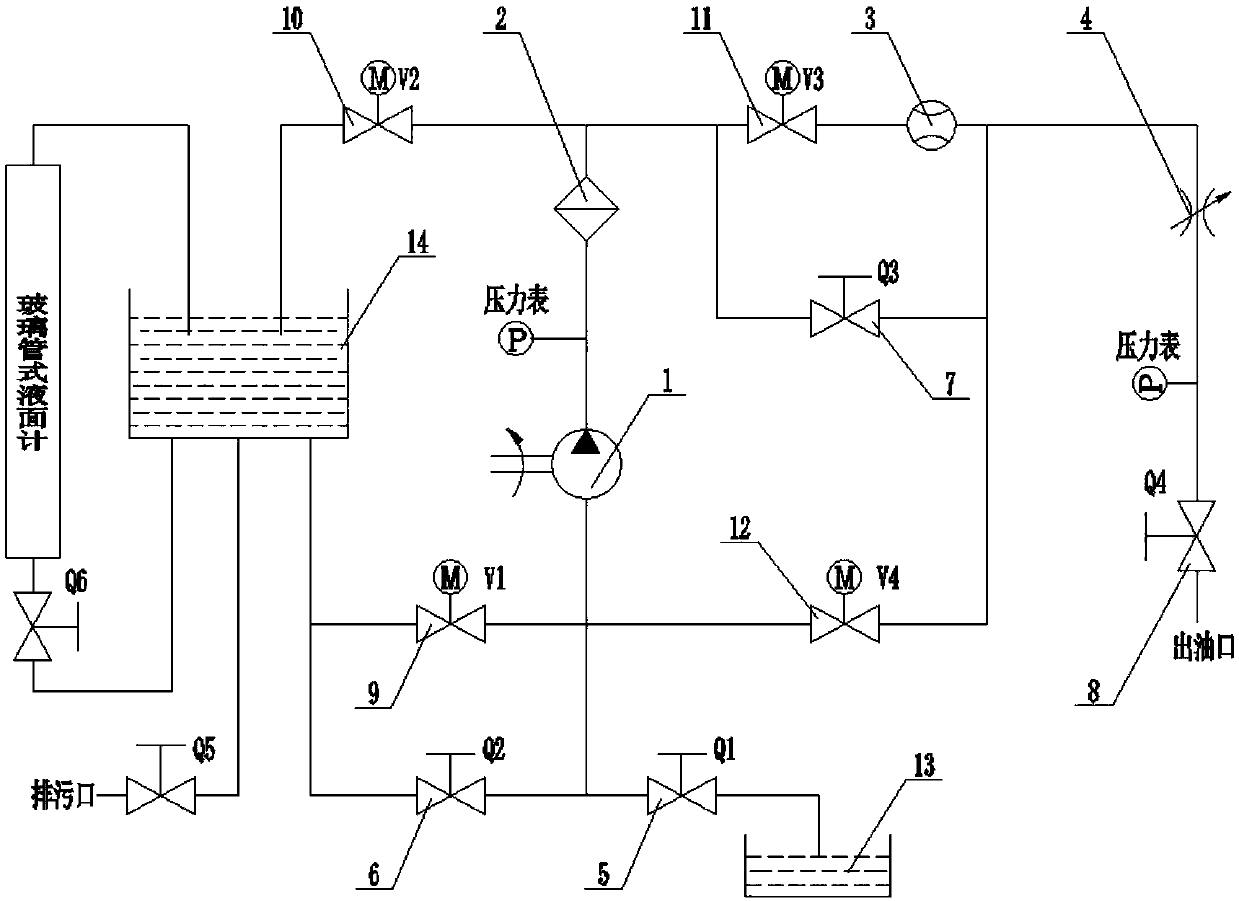

[0018] 1. If figure 1 As shown, a multifunctional fuel filling pipeline system includes a fuel delivery pump (1), a filter (2), a flow meter (3), a throttle valve (4), a three-piece ball valve (5, 6, 7 , 8), normally closed solenoid valves (9, 10, 11, 12), external container (13) and oil carrying tank (14); Close the electromagnetic valve (10), filter (2), oil delivery pump (1) and three-piece ball valve (5) and then connect the external container (13); The three-piece ball valve (6) is connected in series between the ball valves (5); the pipeline drawn between the normally closed solenoid valve (10) and the filter (2) is sequentially connected in series with the normally closed solenoid valve (11), the flow meter (3 ), the throttle valve (4), and the three-piece ball valve (8) are connected to the oil outlet; the lower oil port of the oil carrying tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com