Preparation method of pure acetic acid bazedoxifene crystal form A

A technology of xifen crystal form and acetic acid, which is applied in the field of preparation of pure bazedoxifene acetate crystal form A, can solve the problems of high drug prices, complicated processes, and high production costs, and achieve easy operation, simple process, and improved production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

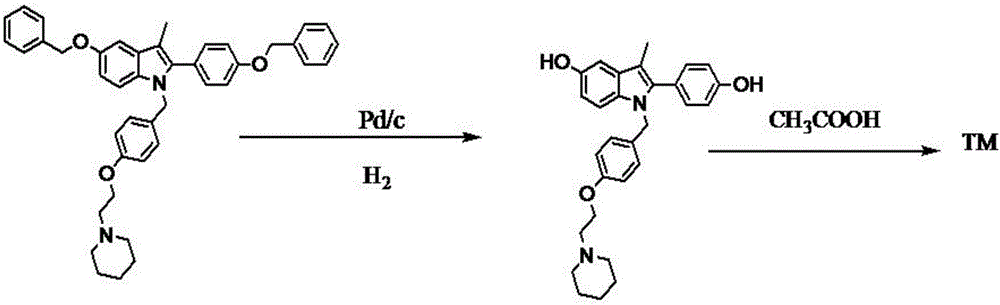

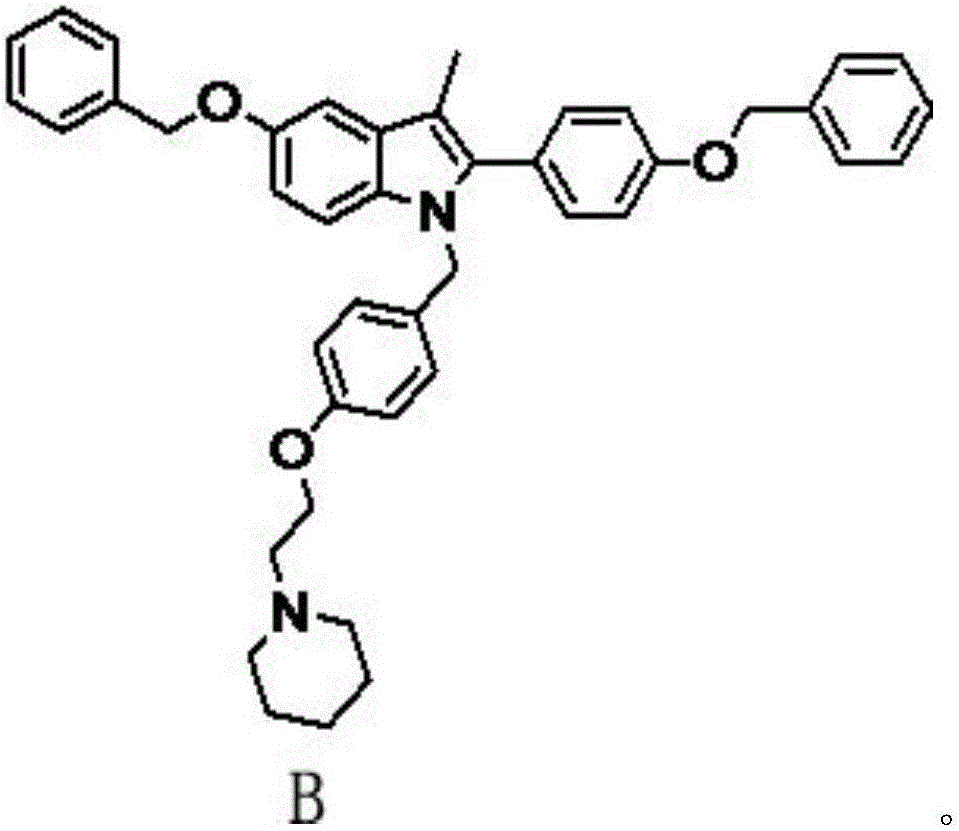

[0019] Such as figure 1 Shown, a kind of preparation method of pure bazedoxifene acetate crystal form A comprises the following processing steps:

[0020] (1) Take 500ml of absolute ethanol as a solvent, add 50g of raw materials, 1.5g of palladium carbon, flow hydrogen, and react in a closed room at room temperature for 2h;

[0021] (2) Filter off the palladium carbon, first add 2.5g acetic acid dropwise to the filtrate at room temperature, stir for 30min, cool to -5°C ~ 0°C, then add 2.5g acetic acid dropwise, stir for 30min, warm up to room temperature, then add 2.5g dropwise Acetic acid, stirred for 30 min, filtered and dried to obtain the crude product of crystal form A.

Embodiment 2

[0023] A preparation method of pure bazedoxifene acetate crystal form A, comprising the following processing steps:

[0024] (1) Take 200ml of anhydrous methanol as a solvent, add 30g of raw materials, 1.0g of palladium carbon, flow hydrogen, and react in a closed room at room temperature for 2h;

[0025] (2) Filter out palladium carbon, first add 1.5g acetic acid dropwise to the filtrate at room temperature, stir for 30min, cool to -10°C ~ 15°C, then add 1.5g acetic acid dropwise, stir for 30min, warm up to room temperature, then add 1.5g dropwise Acetic acid, stirred for 30 min, filtered and dried to obtain the crude product of crystal form A.

Embodiment 3

[0027] A preparation method of pure bazedoxifene acetate crystal form A, comprising the following processing steps:

[0028] (1) Take 400ml of anhydrous isopropanol as a solvent, add 40g of raw materials, 1.3g of palladium carbon, flow hydrogen, and react in a closed room at room temperature for 2h;

[0029] (2) Filter out the palladium carbon, first add 2 g of acetic acid dropwise to the filtrate at room temperature, stir for 30 min, cool to -10°C to 0°C, then add 2 g of acetic acid dropwise, stir for 30 min, warm up to room temperature, then add 2 g of acetic acid dropwise, and stir After 30 minutes, it was filtered and dried to obtain the crude product of Form A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com