Special rubber sponge foam material with high flame resistance and high tear strength and application

A high tear strength, special rubber technology, applied in the field of neoprene sponge foam material, can solve the problem of the flame retardancy of neoprene rubber, and achieve the effect of high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

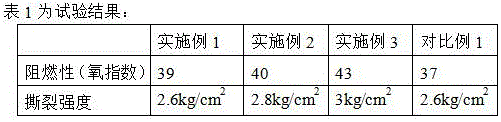

Examples

Embodiment 1

[0025] A special rubber sponge foam material with high flame retardancy and high tear strength, consisting of the following components in parts by weight: 55 parts of neoprene rubber, 12 parts of rubber softening oil, 6 parts of vulcanized ointment, and 5 parts of foaming agent 4 parts of zinc oxide, 6 parts of magnesium oxide, 0.6 parts of vulcanization accelerator, 6 parts of antimony trichloride, 8 parts of decabromodiphenyl ether, 2 parts of antioxidant, 3 parts of activator, and 5 parts of carbon black.

[0026] The preparation method of embodiment 1 is:

[0027] (1) Put chloroprene rubber, vulcanized ointment, carbon black, magnesium oxide, flame retardant decabromodiphenyl ether, antimony trioxide and anti-aging agent into the mixer and knead for 5-6 minutes;

[0028] (2) When the temperature of the rubber material rises to 105~110℃, add rubber softening oil, foaming agent, zinc oxide, vulcanization accelerator and activator, continue mixing for 3~4 minutes, and dischar...

Embodiment 2

[0033] A special rubber sponge foam material with high flame retardancy and high tear strength, which consists of the following components in parts by weight: 70 parts of neoprene rubber, 18 parts of rubber softening oil, 7 parts of vulcanized ointment, and 6 parts of foaming agent 4 parts of zinc oxide, 3 parts of magnesium oxide, 0.7 parts of vulcanization accelerator, 10 parts of antimony trichloride, 7 parts of decabromodiphenyl ether, 1 part of antioxidant, 1 part of activator, and 3 parts of carbon black.

[0034] The preparation method of this embodiment is identical with embodiment 1.

Embodiment 3

[0036] A special rubber sponge foam material with high flame retardancy and high tear strength, consisting of the following components in parts by weight: 90 parts of neoprene rubber, 22 parts of rubber softening oil, 15 parts of vulcanized ointment, and 9 parts of foaming agent 5 parts of zinc oxide, 3 parts of magnesium oxide, 0.6 parts of vulcanization accelerator, 15 parts of antimony trichloride, 20 parts of decabromodiphenyl ether, 3 parts of antioxidant, 3 parts of activator, 10 parts of carbon black, paraffin wax 3 parts, 3 parts of tackifier, 3 parts of dispersant.

[0037] The preparation method of embodiment 3 is:

[0038] (1) Put chloroprene rubber, vulcanized ointment, carbon black, magnesium oxide, flame retardant decabromodiphenyl ether, antimony trioxide and antioxidant, paraffin, tackifier, and dispersant into the mixer for mixing 5~6 minutes;

[0039] (2) When the temperature of the rubber material rises to 105~110℃, add rubber softening oil, foaming agent,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap