Pearlescent button and preparation method thereof

A button and pearlescent technology, applied in the field of clothing production, can solve the problems of no specificity, single product structure, uniform pearlescent direction, etc., and achieve the effects of good impact resistance, low cost and good color fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

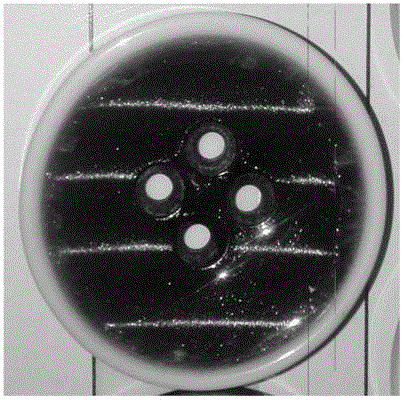

Image

Examples

preparation example Construction

[0048] The invention discloses a preparation method of a pearlescent button, which is characterized in that it comprises the following steps:

[0049] A) After uniform mixing of epoxy resin and magnetic pearl powder, adding curing agent and mixing uniformly again to obtain glue-dropping slurry;

[0050] B) Drop the glue-dropping slurry obtained in the above step A) on the surface of the button semi-finished product, and leave it to stand under the action of a magnetic field to obtain a pearlescent button.

[0051] In the above-mentioned preparation method of the present invention, the optimal principle and the added amount of the raw materials used are the same as those in the above-mentioned drip glue slurry, and will not be repeated here.

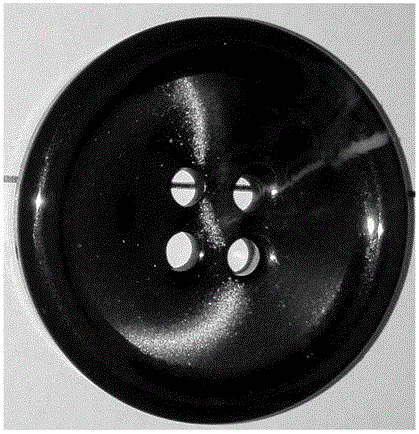

[0052] In the present invention, epoxy resin and magnetic pearl powder are uniformly mixed at first, and then a curing agent is added to mix uniformly again to obtain glue-dropping slurry; the viscosity of the glue-dropping slurry is prefer...

Embodiment 1

[0073] Mixed slurry for blank making: mix 710g of 989 unsaturated resin with 290g of styrene to obtain a mixed solution, then add 10ml of cobalt naphthenate to it and stir well, then add 8ml of methyl ethyl ketone peroxide, and stir evenly , to obtain the billet slurry.

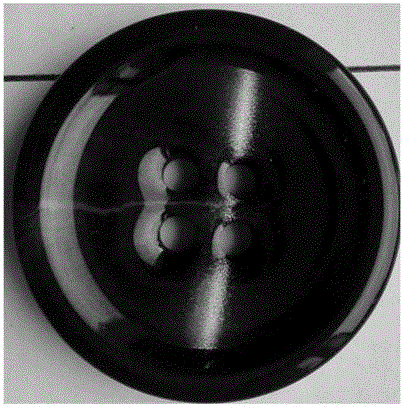

[0074] Blank-making and button-making process: After the blank-making slurry obtained in the above steps is processed by a centrifuge, a button blank with a thickness of 5.5mm is obtained; then the button blank is made into a button blank with a side thickness of 4.0mm and a diameter of 20.0mm, depth 1.5mm, hole distance 5.0mm and hole diameter 2.1mm button shape, and finally get the resin button blank.

[0075] Initial polishing: Pour the resin button blanks made by the button making machine into the polishing machine, and carry out water tumbling polishing with a polishing stone for 5 hours to remove the burrs and uneven knife feet left during the button making.

[0076] Fine polishing: Put the dried resin...

Embodiment 2

[0083] Mixed slurry for blank making: Mix 750g of 989 unsaturated resin with 300g of styrene to obtain a mixed solution, then add 11ml of cobalt naphthenate and stir well, then add 9ml of methyl ethyl ketone peroxide, and stir well , to obtain the billet slurry.

[0084] Blank-making and button-making process: After the blank-making slurry obtained in the above steps is processed by a centrifuge, a button blank with a thickness of 6.0mm is obtained; then the button blank is made into a button blank with a side thickness of 4.5mm and a diameter of 25.3mm, depth 1.6mm, hole distance 5.5mm and hole diameter 2.25mm button shape, and finally get the resin button blank.

[0085] Initial polishing: Pour the resin button blanks made by the button making machine into the polishing machine, and carry out water tumbling polishing with a polishing stone for 6 hours to remove the burrs and unevenness of the knife feet left during the button making.

[0086] Fine polishing: Put the dried r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com