Heat treatment method for 2Cr3WMoV material gear forging

A heat treatment method and heat treatment furnace technology, which are applied in metal material coating process, coating, solid diffusion coating and other directions, can solve problems such as unqualified, and achieve high hardness, high wear resistance, and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A heat treatment method for a 2Cr3WMoV material gear forging is provided:

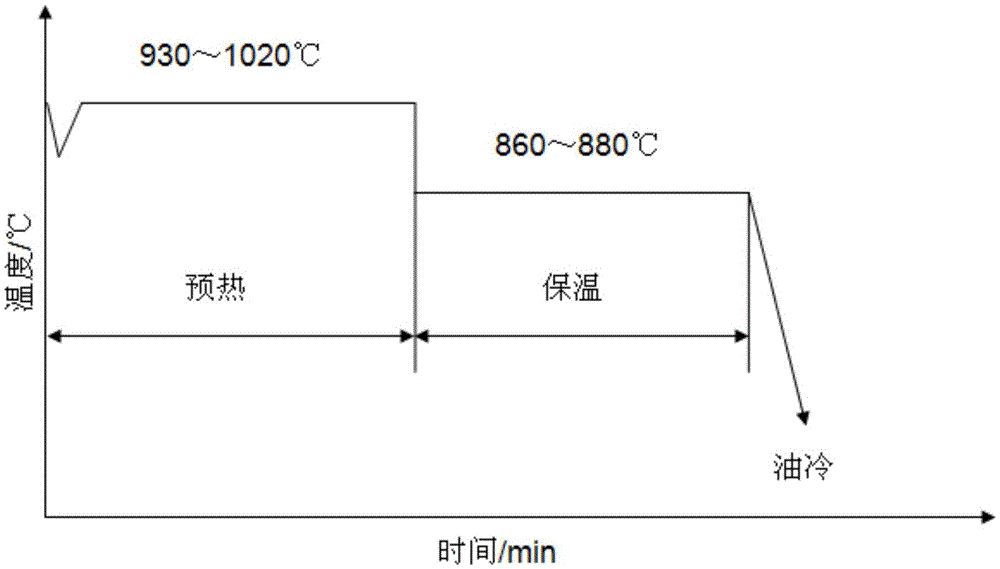

[0023] Step 1. Preprocessing

[0024] Process the bar of 2Cr3WMoV material into gear forgings, put the gear forgings into the heat treatment furnace to heat after cooling, and then normalize; after normalizing, quench and temper the gear forgings; and adopt lower temperature and lower carbon potential to enter the furnace , reduce internal stress and prevent cracks.

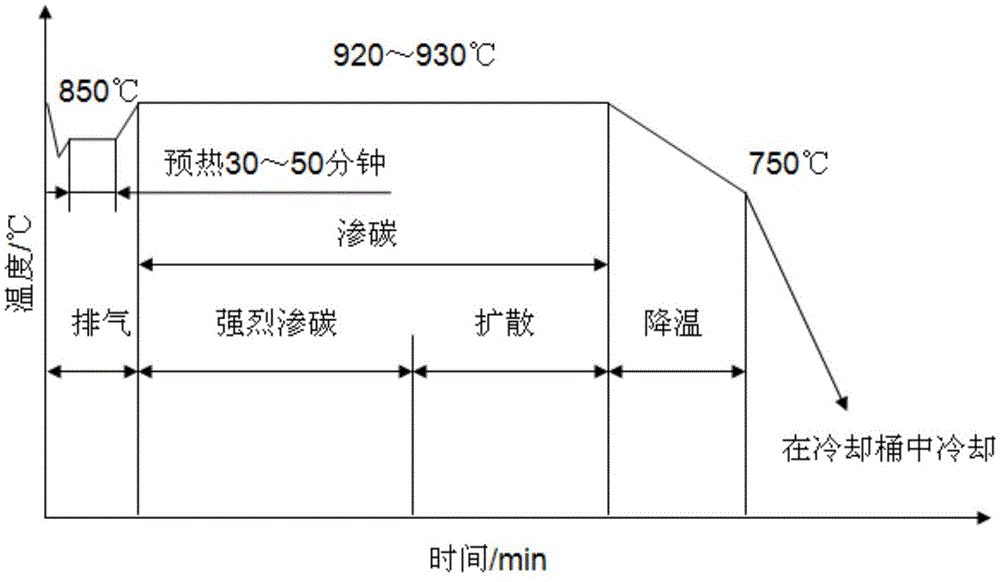

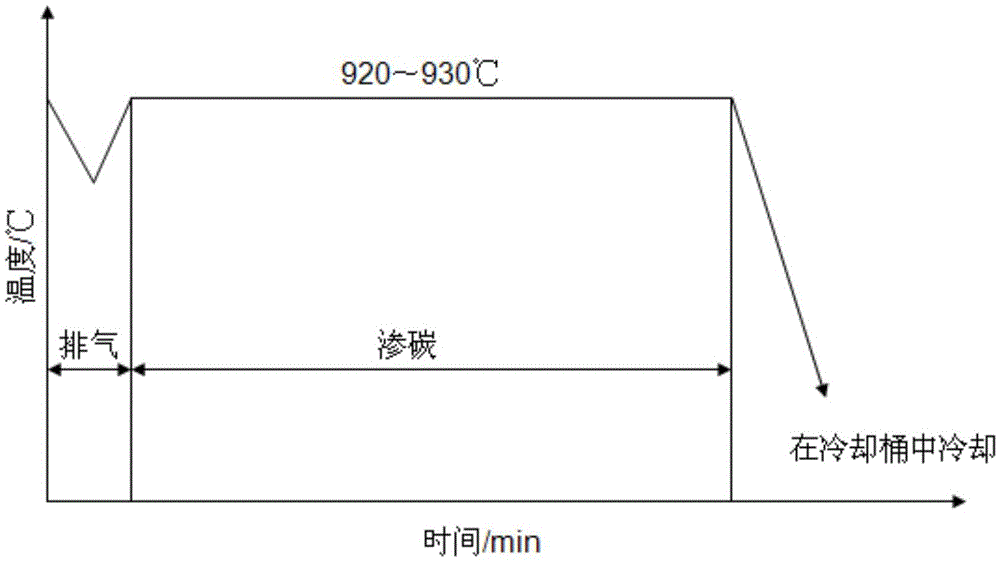

[0025] Step two, two-stage carburizing

[0026] Put the gear forging into a carburizing furnace, and carry out two-stage carburizing on the gear forging continuously, wherein the carbide grade in the two-stage carburizing is controlled to be ≤6 grade, and the depth of the carburized layer after the two-stage carburizing is 1.25-1.4 mm;

[0027] In the first stage of carburizing, the carbon potential is 1.1-1.3, the heating temperature is 925±5°C, the heat preservation is 3.5-4.5 hours, and the high carbon concentration gradient ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com