An automatic entry and exit tank system for the cathode plate of the electrolytic manganese post-processing production line

A technology of cathode plates and access tanks, which is applied in photography technology, instruments, photography auxiliary technology, etc., can solve problems such as heavy metal waste liquid pollution, achieve the effects of reducing pollution, improving production efficiency, and ensuring utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

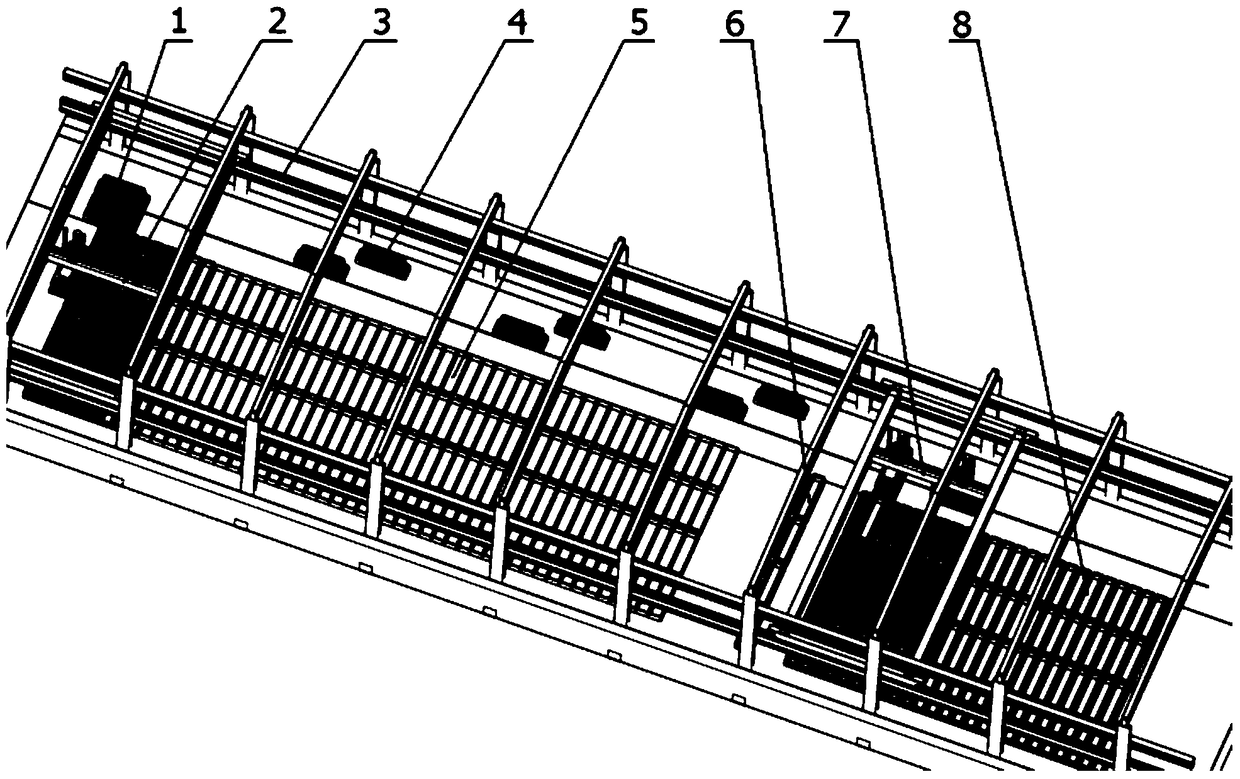

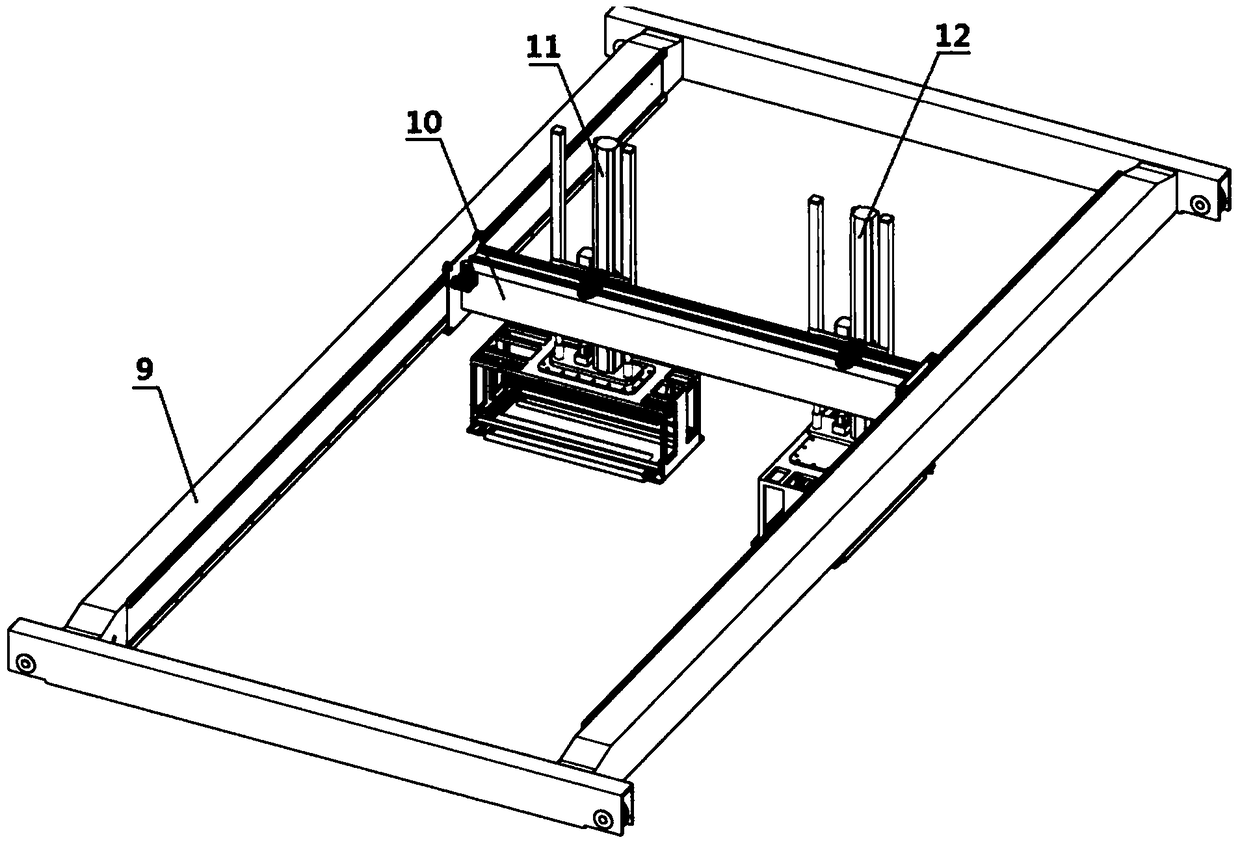

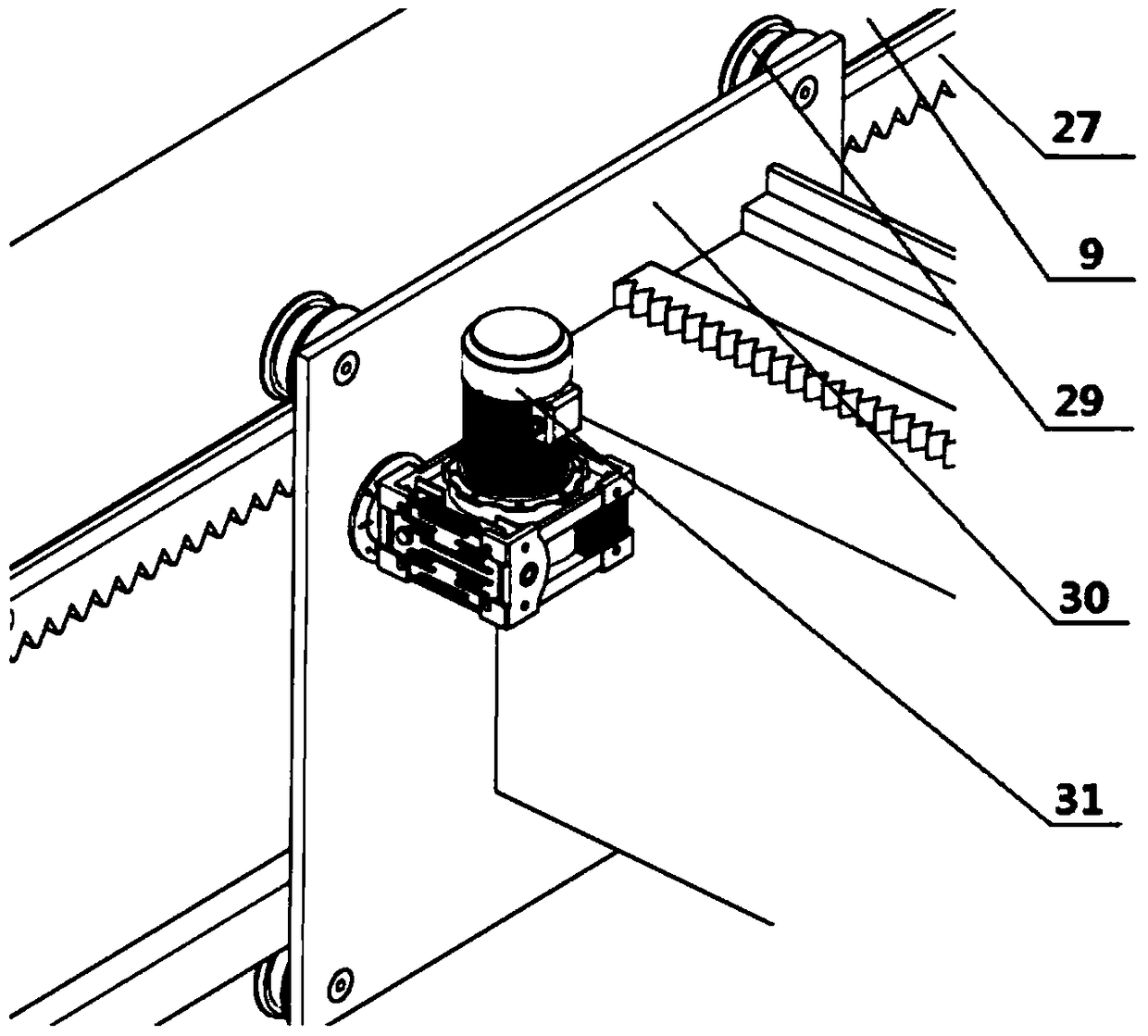

[0033] like figure 1 As shown, the cathode plate automatic entry and exit tank system of a kind of electrolytic manganese post-processing production line provided by the present invention includes heavy metal reduction AGV car 1, access tank crane 2, guide rail 3, transfer AGV car 4, ground electrolyzer 5, automatic post-processing The equipment 6 and the transfer crane 7, wherein the access trough crane 2 and the transfer crane 7 span the top of the workshop, and can be slidably installed on the guide rail 3 placed on the column of the workshop, the access trough crane 2 and the transfer Crane 7 carries out moving operation through guide rail 3 as carrier. The heavy metal reduction AGV vehicle 1 and the transfer AGV vehicle 4 are located on the side of the column of the workshop, and are close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com