Detachable road steel bridge carrying erecting vehicle achieving low-position mounting and butt joint

A technology of dismantling and erecting vehicles, which is applied in the direction of bridge construction, erection/assembly of bridges, bridges, etc. It can solve the problems that affect the efficiency of truss docking, the position is fixed and cannot be changed, and the whole cannot be disassembled, so as to expand the versatility and scope of application. Increased scope of application, ease of maintenance and guaranteed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

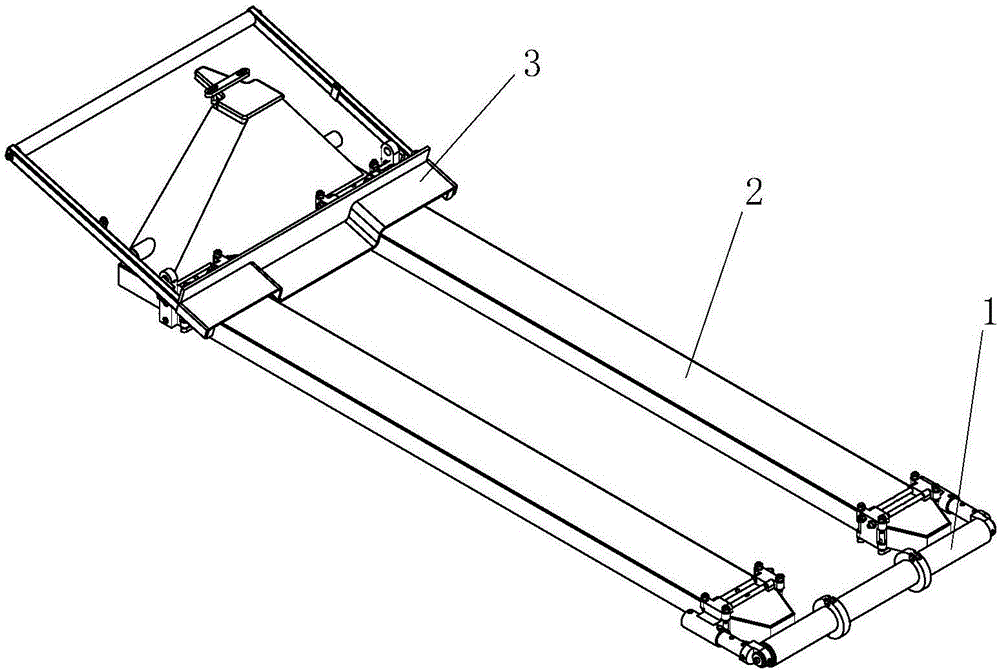

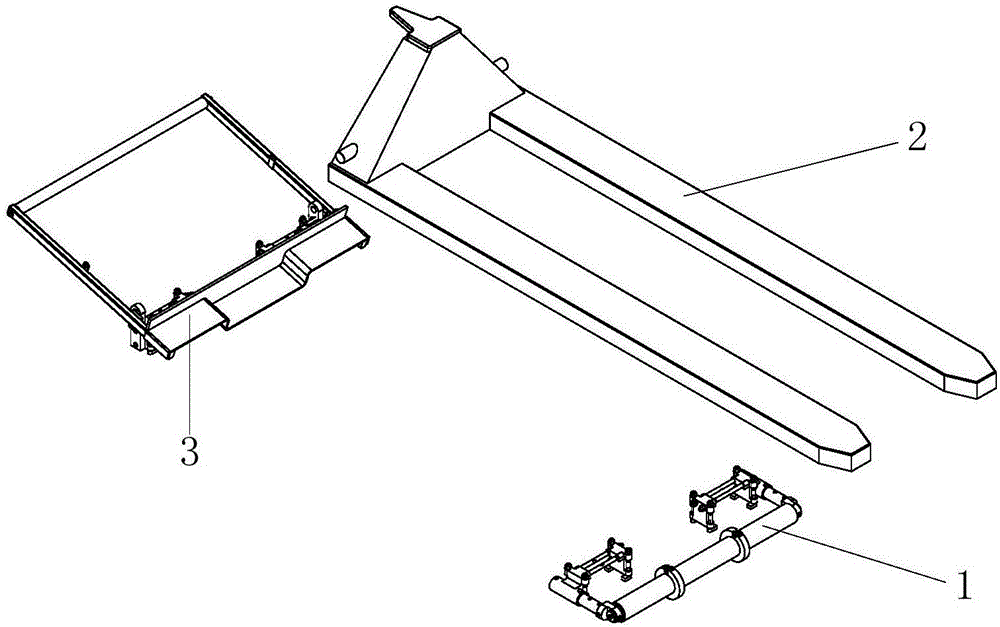

[0037] As shown in Figure 1(a) and Figure 1(b), the detachable highway steel bridge transport and erection vehicle with low-level installation and docking is composed of a front lifting roller assembly 1, a car body 2 and a lifting plate assembly 3; the front lifting roller The assembly 1 straddles the two forks of the vehicle body 2 and is installed on the front side of the vehicle body 2 along the horizontal direction; the lifting plate assembly 3 is installed on the rear side of the vehicle body 2 .

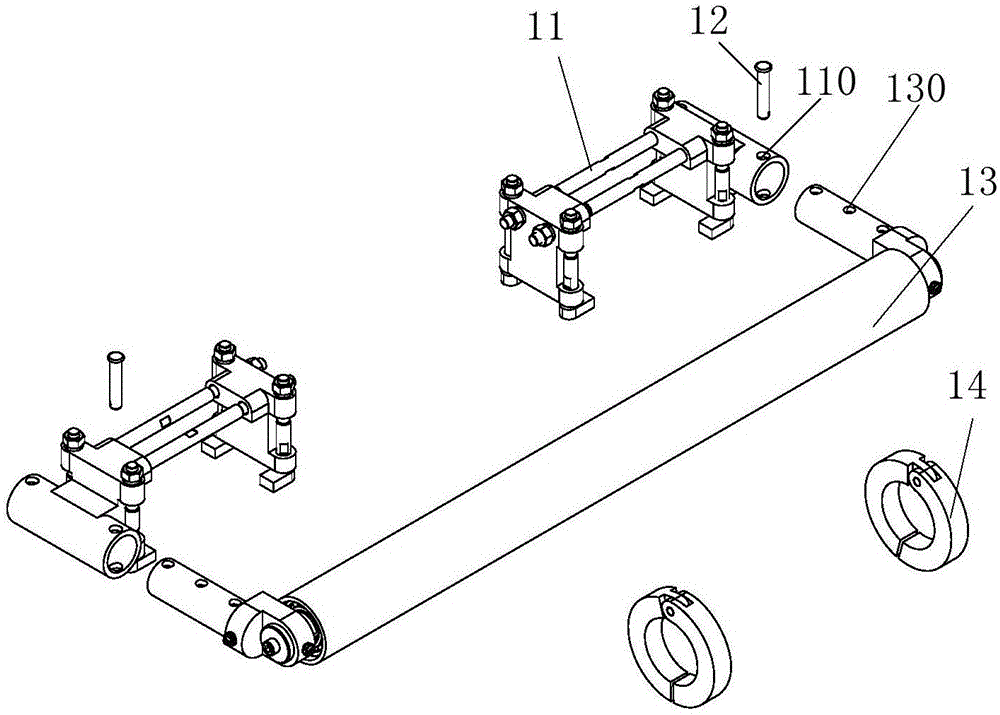

[0038] Such as figure 2 As shown, the front lifting roller assembly 1 is composed of a front mounting seat assembly 11, a pin shaft 12, a lifting roller assembly 13, and a retaining ring assembly 14; there is at least one position adjustment hole 110 on the front mounting seat assembly 11 , there is at least one position adjustment h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com