A gravel-variable cross-section pile composite structure with drainage and anti-sliding functions and its construction method

A technology of variable cross-section piles and composite structures, which is applied in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of no drainage effect, weakened shear and bending strength, etc., and achieve the effect of reducing construction costs and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

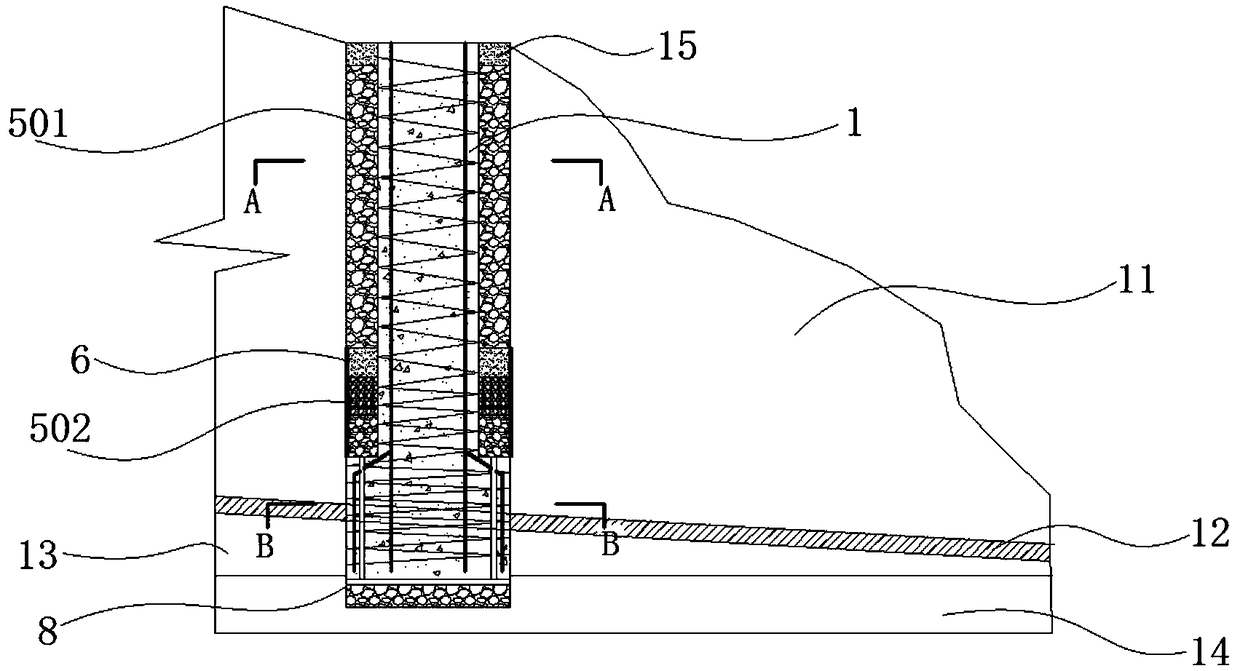

[0042] This embodiment discloses a gravel-variable cross-section pile composite structure with drainage and anti-sliding functions, including: a reinforced concrete variable cross-section pile 1 implanted in a landslide body 11 .

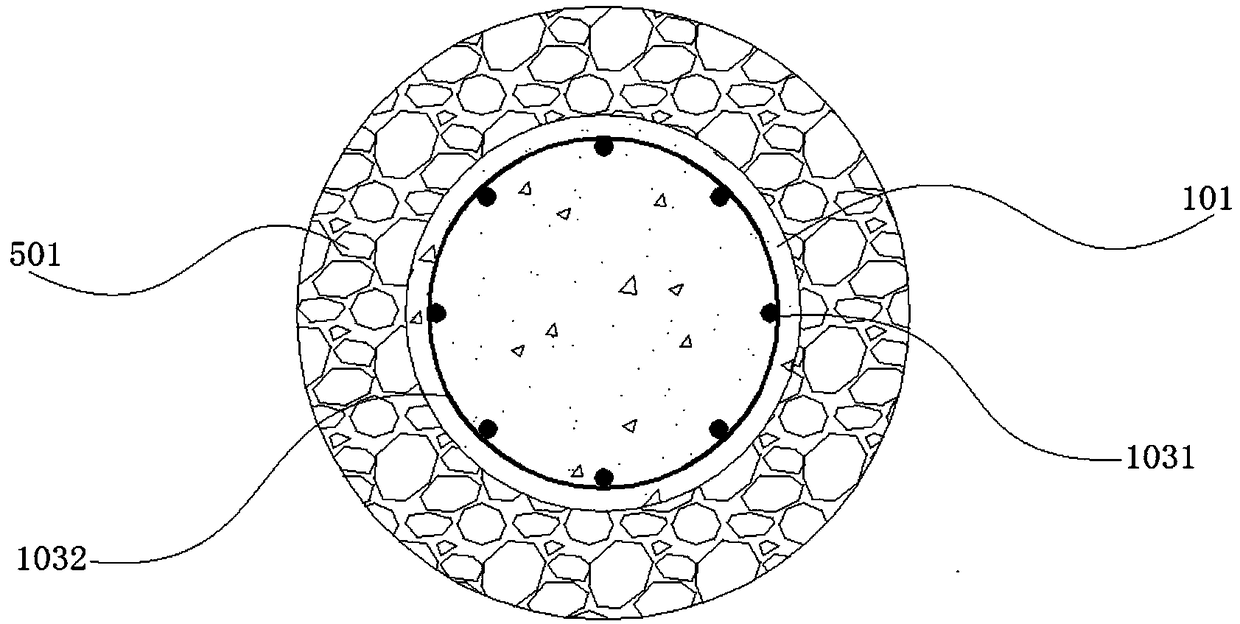

[0043] see figure 2 , the reinforced concrete variable-section pile 1 includes a small-section pile 101 and a large-section pile 102 . The large-section pile 102 is arranged at the bottom of the small-section pile 101 . The small-section pile 101 and the large-section pile 102 are integrated. The reinforced concrete variable cross-section pile 1 has the main reinforcement 1031 of the pile body and the spiral stirrup 1032 of the pile body. The main reinforcement 1031 of the pile body and the spiral stirrup 1032 of the pile body together form a reinforcement cage 103 .

[0044] see figure 1 , image 3 and Figure 4 , the small-section pile 101 and the large-section pile 102 are both round piles. The pile diameter ratio of the small-section pil...

Embodiment 2

[0052] This embodiment discloses a gravel-variable cross-section pile composite structure with drainage and anti-sliding functions, including: a reinforced concrete variable cross-section pile 1 implanted in a landslide body 11 .

[0053] The reinforced concrete variable-section pile 1 includes a small-section pile 101 and a large-section pile 102 . The large-section pile 102 is arranged at the bottom of the small-section pile 101 . The small-section pile 101 and the large-section pile 102 are integrated. The reinforced concrete variable cross-section pile 1 has the main reinforcement 1031 of the pile body and the spiral stirrup 1032 of the pile body. The main reinforcement 1031 of the pile body and the spiral stirrup 1032 of the pile body together form a reinforcement cage 103 .

[0054] see Figure 5 and Figure 6 After the large-section pile 102 passes through the sliding surface 12, it is embedded in the stable bedrock 13 below, and the embedding depth meets the requir...

Embodiment 3

[0063] This embodiment discloses a construction method of the gravel-variable cross-section pile composite structure with drainage and anti-sliding functions described in Embodiment 1, including the following steps:

[0064] 1) Prefabricated reinforced concrete variable section pile 1.

[0065] 2) According to the geological conditions, excavate the pile hole to the design depth. The diameter of the pile hole is x, and the diameter of the large section pile 102 is y. Among them, x-y=20~50mm.

[0066] 3) Lay gravel drainage cushion 8 at the bottom of the pile hole.

[0067] 4) Lift the reinforced concrete variable section pile 1, align the pile position, adjust the verticality of the reinforced concrete variable section pile 1, and then put the reinforced concrete variable section pile 1 into the pile hole to the design elevation.

[0068] 5) The design position of the pile hole is surrounded by the geotextile 6, and the reverse filter layer 502 is applied layer by layer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com