Mulching soil removing device for cave of phosphorite mine

A clearing device and mining technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of large working load and impact load, reduced service life of gear rod and tooth tip, and increased cost, so as to speed up loosening, Easy to excavate and transport, increase the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

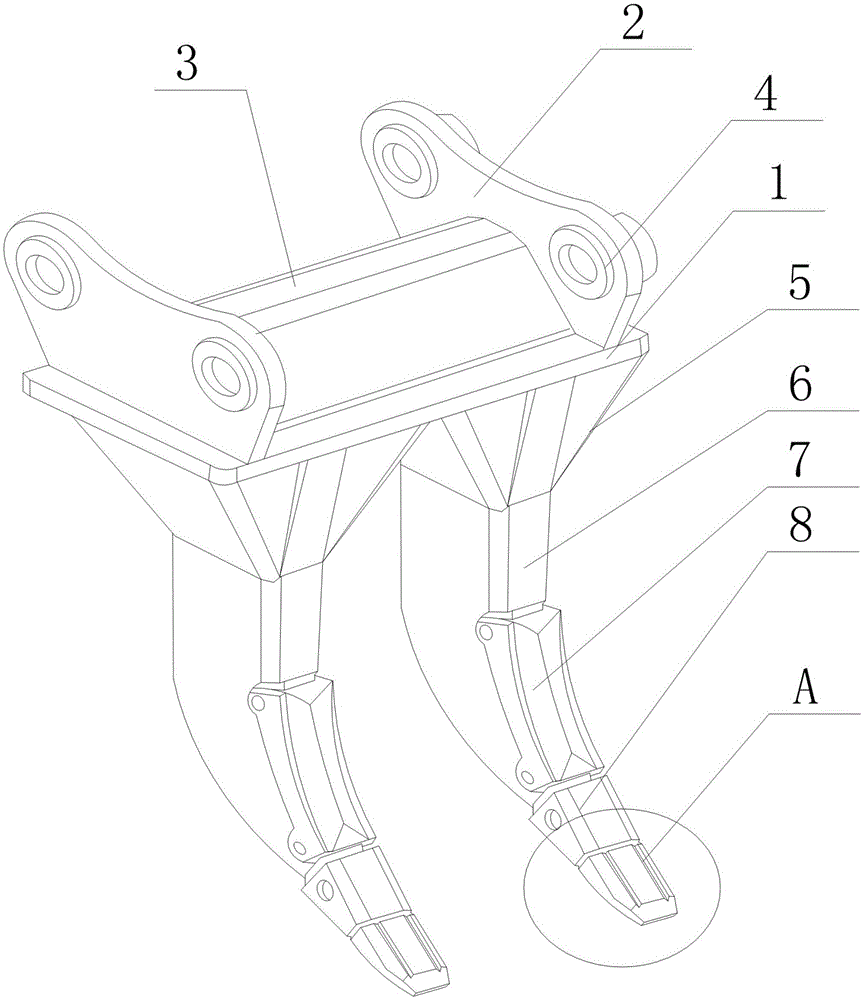

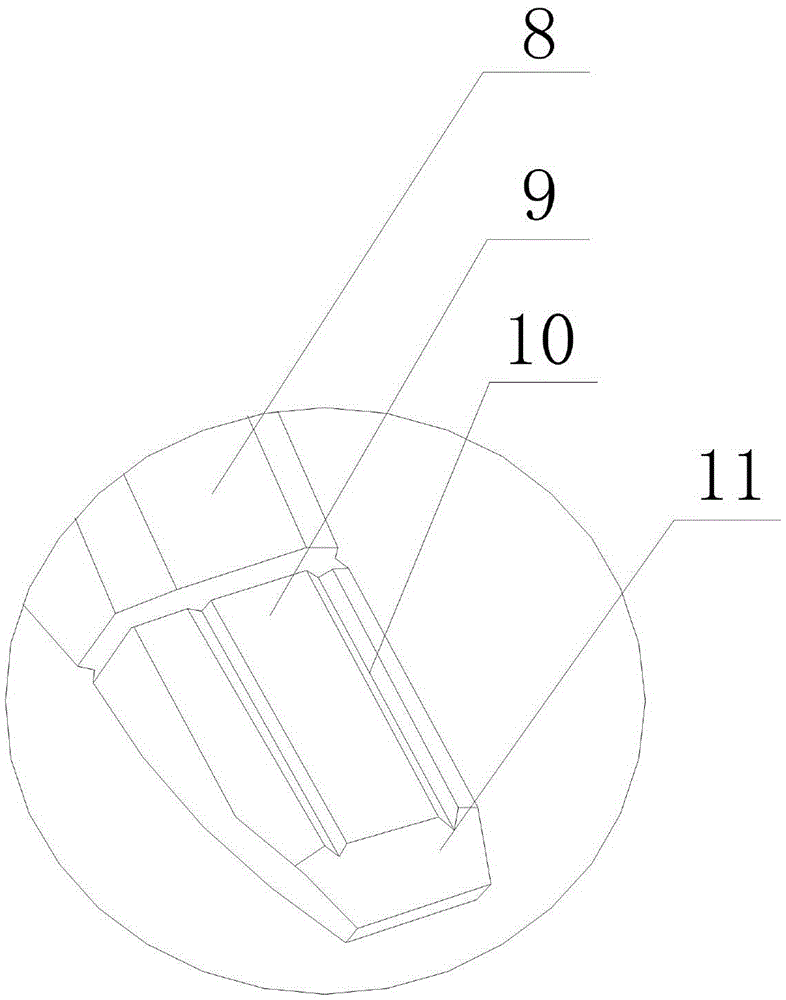

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes a square connecting plate 1, lugs 2 with shaft holes 4 are installed on both sides of the upper part of the connecting plate, and a trapezoidal reinforcing plate 3 is welded between the two lugs 2, Weld two or more than two arc-shaped tooth bars 6 with bucket teeth 9 at the bottom middle position of the connecting plate 1, and connect with the outer wall of the tooth bar 6 at the square peripheral edge of the connecting plate 1 A reinforcing plate 5 is welded between them, and the distance between the upper ends of two adjacent gear rods 6 is 40-60 cm, and an alloy sheath 7 is installed on the inner side of the curved surface of the gear rod 6 through a pin shaft, A gear sleeve 8 is installed on the upper part of the bucket tooth 9 through a pin shaft, and two arc-shaped diversion grooves 10 are opened on the inner side wall of the lower part of the bucket tooth 9, and the diversion groove 10 is along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com